Transparent, conducting and textured layer and method of fabrication

A transparent conductive layer, conductive layer technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing the reflection of light and reducing the current generated by light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

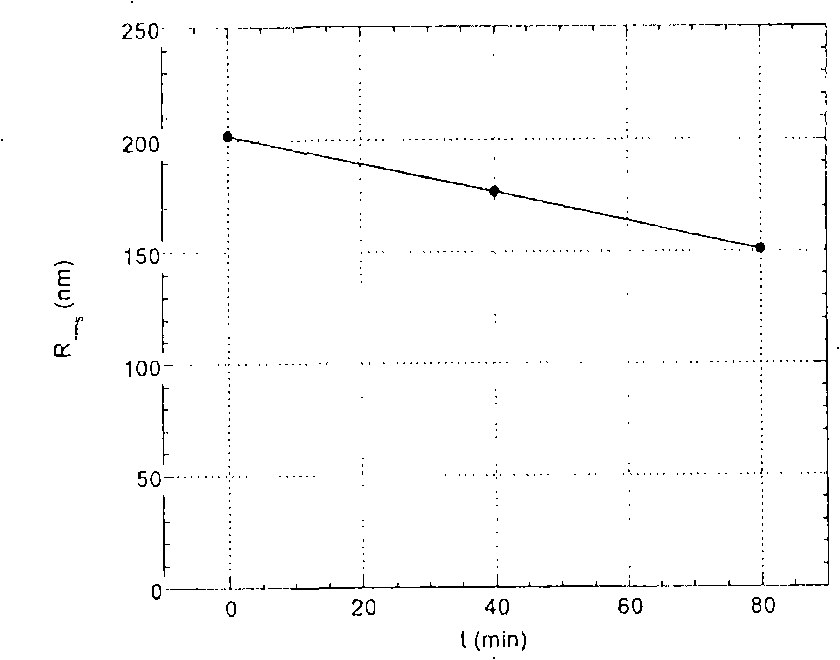

Image

Examples

Embodiment Construction

[0024] Before giving a description of the TCO layer according to the invention and its method of manufacture, we recall that optoelectronic devices, whether they include solar cells or photodetectors, are characterized by conversion properties η and light-harvesting capabilities, as long as the light generates current The collection of is good, the former term depends on the latter term.

[0025] The conversion performance η of a device of this type is given by the ratio between the electrical power supplied by the device and the received candle power, the supplied power being equal to the product of:

[0026] Short circuit current (I sc )×open circuit voltage (V oc )×fill factor (FF).

[0027] A good characterization of the light-harvesting ability is the photocurrent density provided by the cell at reverse voltage (I inv ) given, this reverse voltage makes it possible to extract all the photogenerated carrier current and thus be independent of V oc And the value of FF to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com