Axial flow fan

An axial flow, fan technology, applied in non-variable displacement pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of no airfoil section, no blade position and angle adjustment. problems, to achieve the effect of fewer parts and lower manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

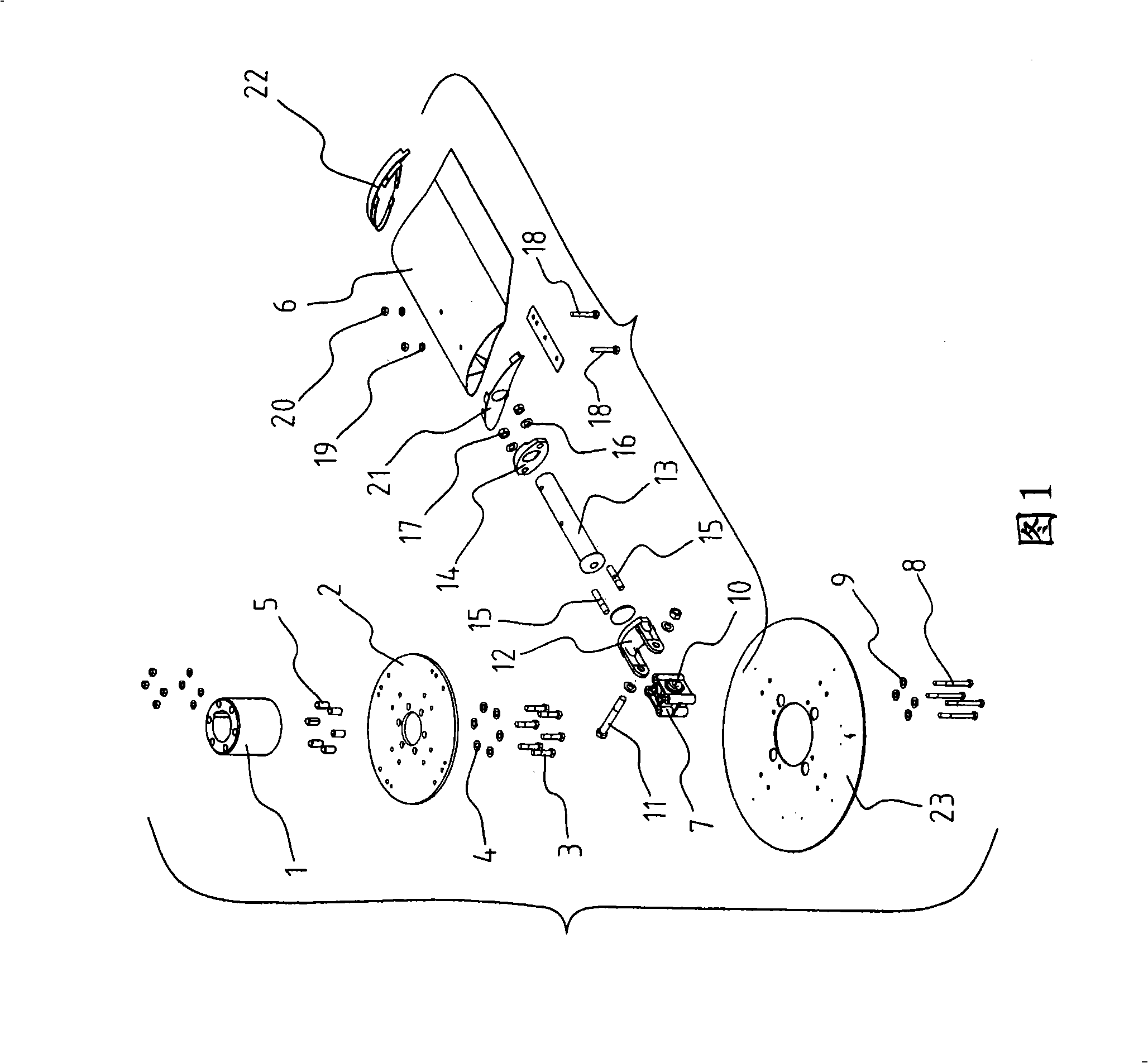

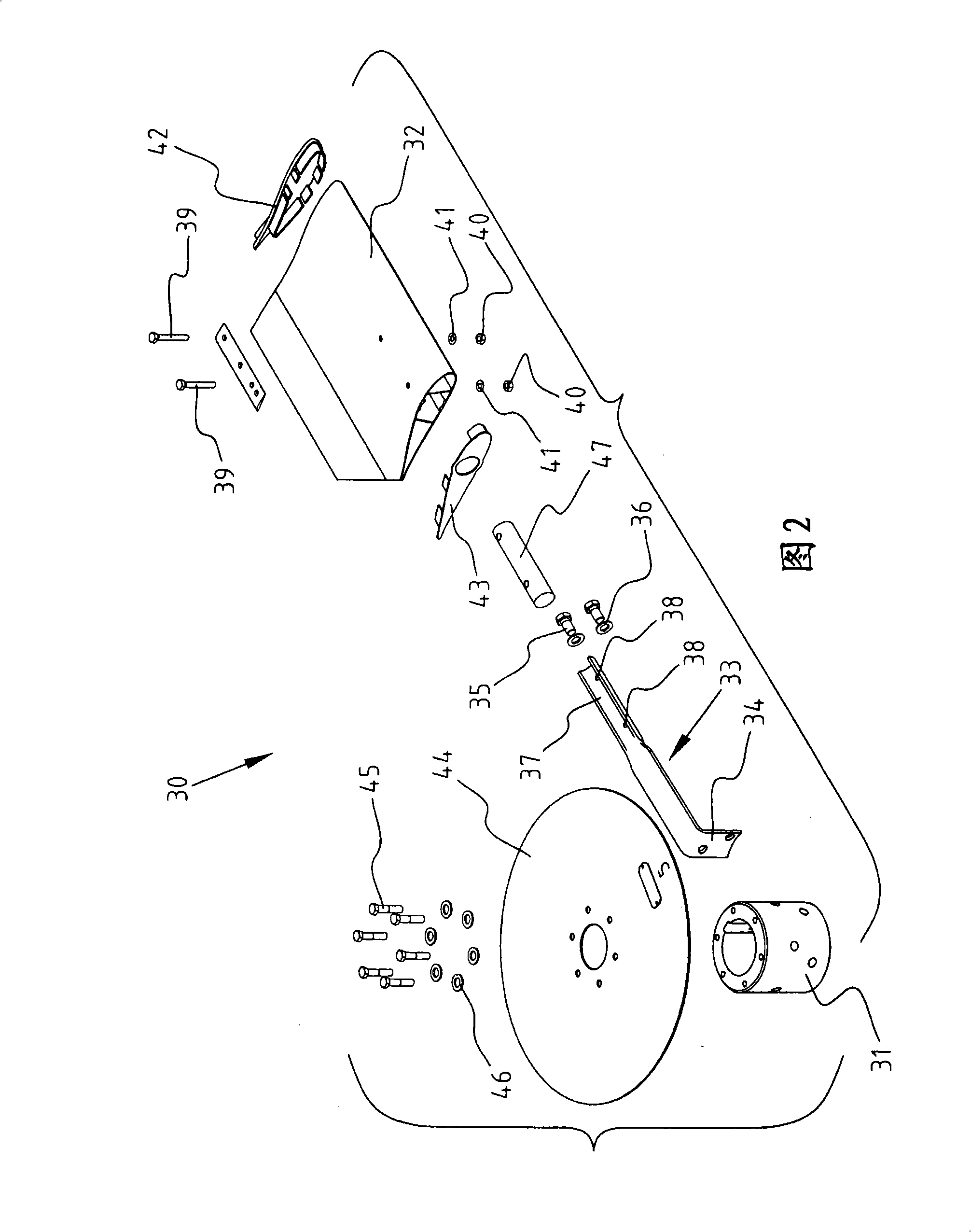

[0028] FIG. 2 shows an axial fan 30 of the present invention. The axial fan 30 includes a hub 31 on which blades 32 are mounted. The L-shaped strap 33 has a short segment 34 of concave shape which is directly bolted to the cylindrical outer surface of the hub 31 by means of bolts 35 and washers 36 . The long section 37 of the L-shaped strip 33 is partially bent and a slot-shaped opening 38 is provided. The curved portion of the long section 37 is inserted into the hollow blade 32 . It is also possible to mount long sections of the L-shaped straps on the outside of the blades. The filler member 47 is also inserted into the blade 32, and then, the bolt 39 is inserted, thereby connecting the L-shaped strap 33, the filler member 47 and the blade 32 together. The bolt 39 is fastened with a nut 40 and a washer 41 .

[0029] The hollow vanes 32 are closed with end caps 42 and 43 .

[0030] Finally, the closure plate 44 is attached to the hub 31 by means of bolts 45 and washers 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com