Rear periphery and kickplate matching structure of automatic escalator step

A technology of escalator and kick plate, applied in the direction of escalator, transportation and packaging, can solve the problem of unimproved step clearance, and achieve the effect of improving the gap, enhancing the rigidity of the kick plate and improving the safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

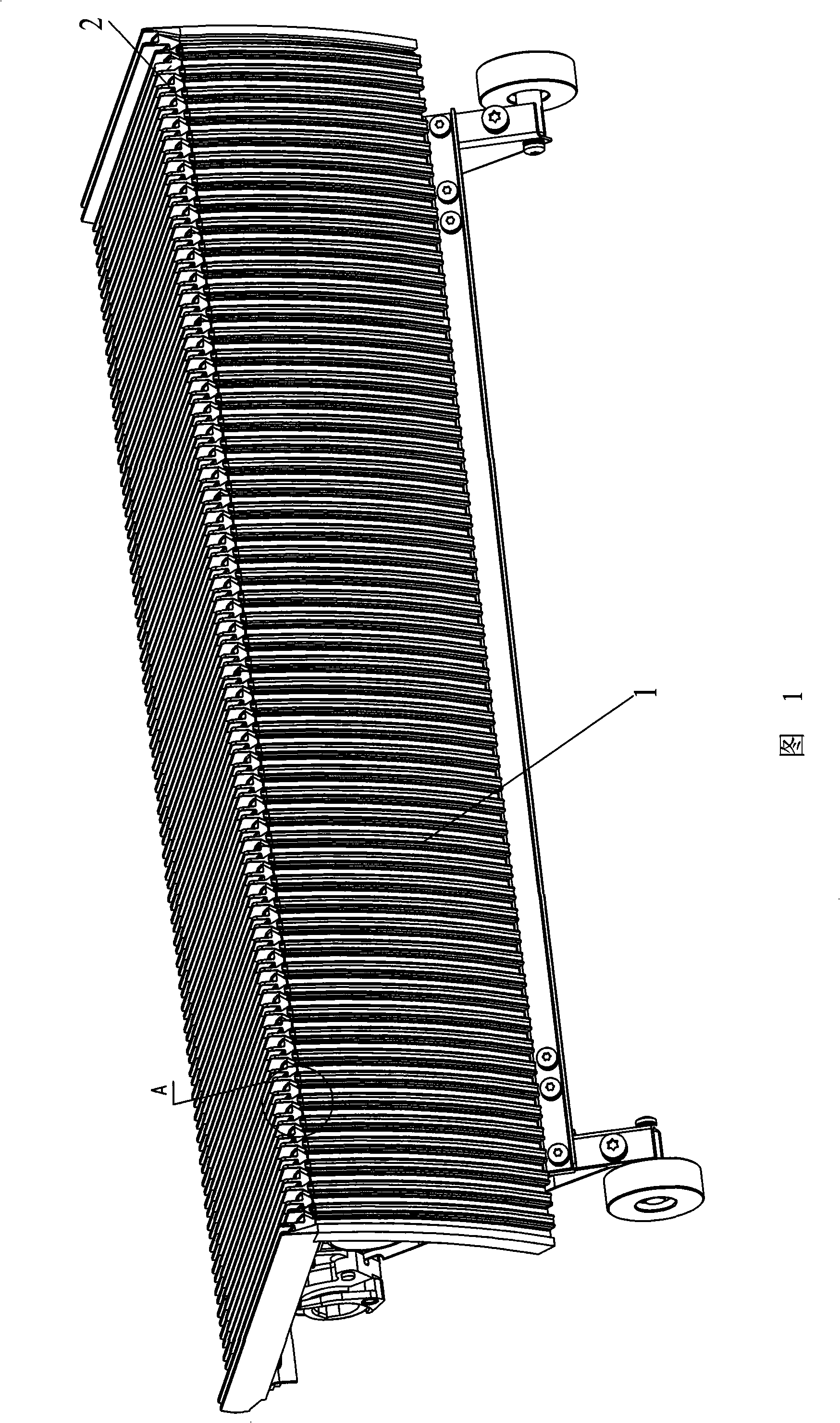

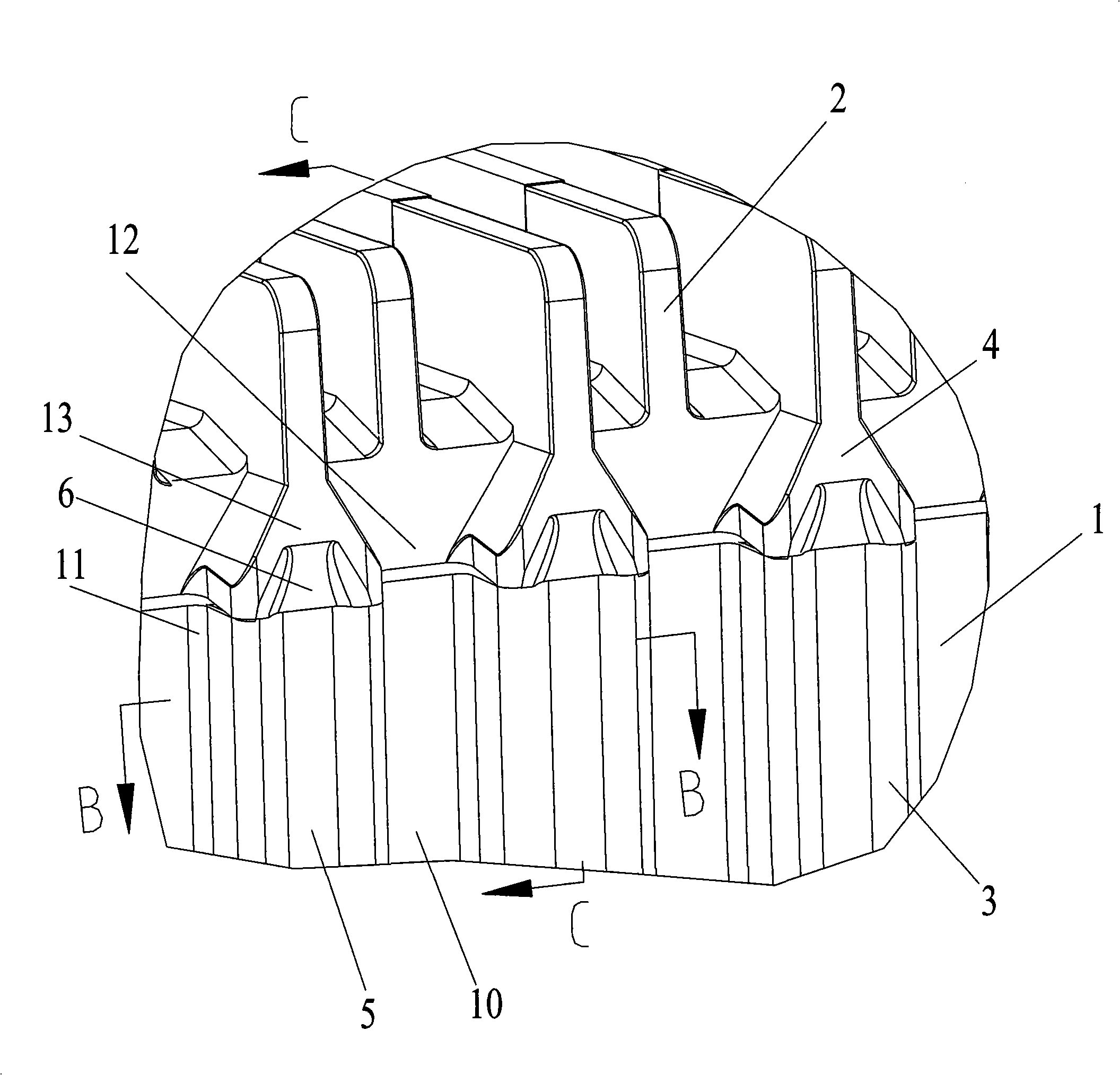

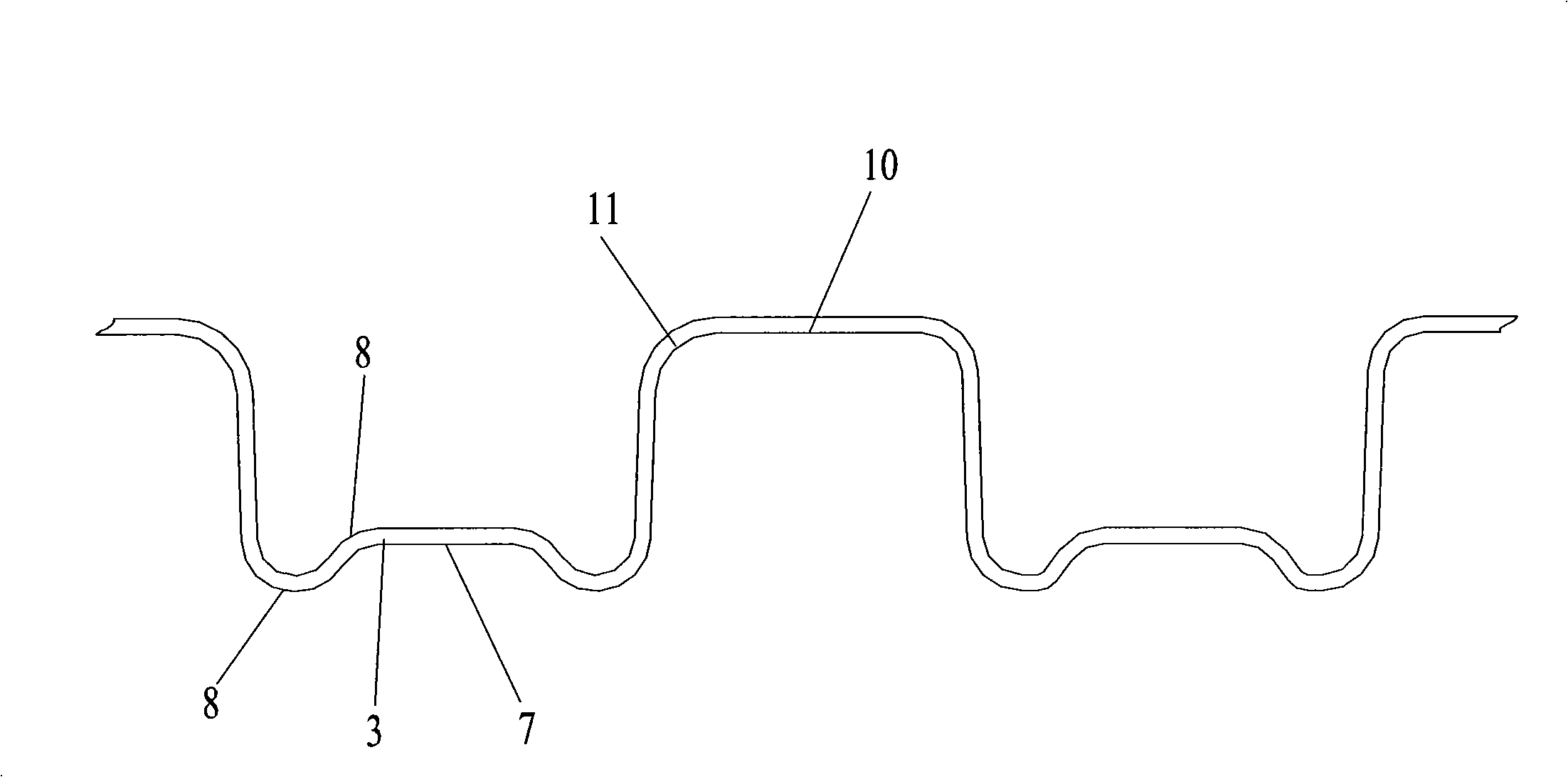

[0019] Embodiment: as shown in Figure 1 to Figure 6 As shown, an escalator step rear boundary and kick plate inlaid structure, including a kick plate 1 and a rear boundary 2 whose lower end is inlaid with the upper end of the kick plate 1, and the surface of the kick plate 1 is evenly provided with several parallel kick plates Convex teeth 3, the rear side of the rear border 2 is provided with a rear protruding tooth 4 corresponding to the kick plate protruding tooth 3, the shape of the lower end of the rear protruding tooth 4 is consistent with that of the kick plate protruding tooth 3 and correspondingly engaged. A kick plate groove 5 is provided on the outer surface of the kick plate convex tooth 3, and a rear boundary groove 6 is provided at the bottom of the rear convex tooth 4, and the lower end of the rear boundary groove 6 is consistent with the shape of the kick plate groove 5 and Corresponding to the engagement, the rear boundary groove 6 gradually transitions upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com