Medium test method for extracting oil and protolysate from peanut with water-enzyme method

A technology of hydrolyzing protein and hydrolyzed protein powder, which is applied in the application field of biotechnology in the food industry, and can solve the problems of unseen water enzymatic oil and hydrolyzed protein pilot scale, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

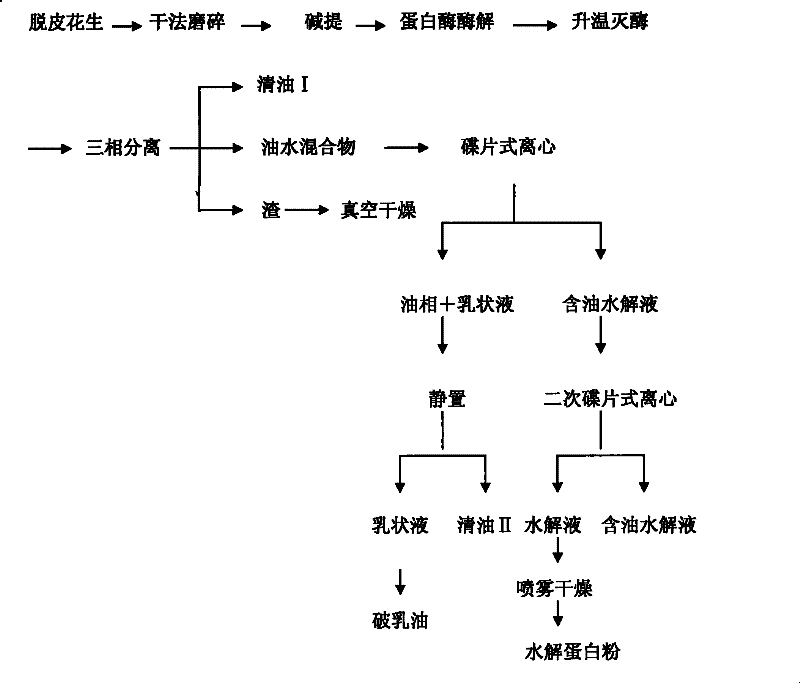

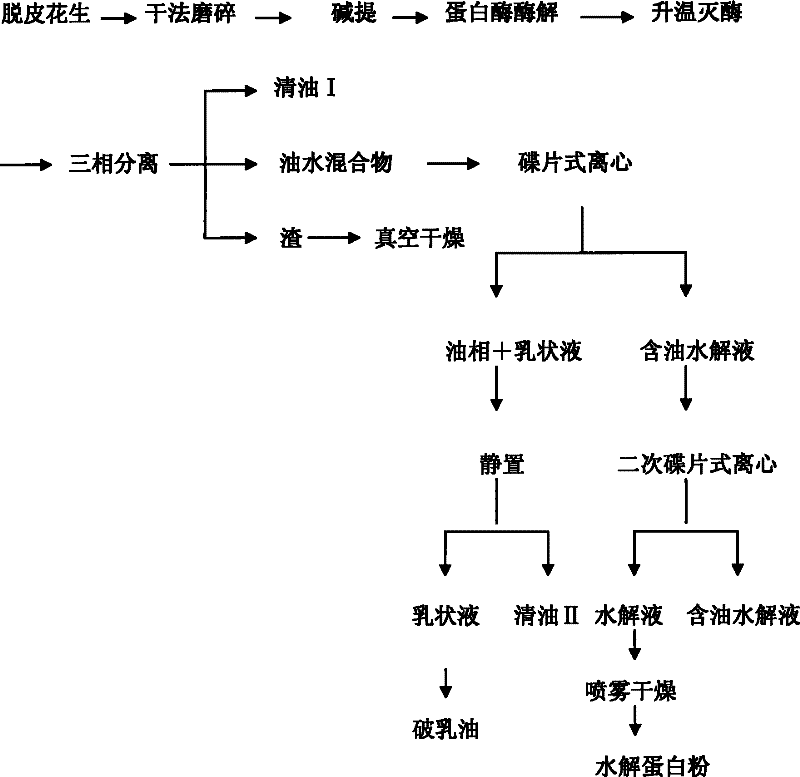

Image

Examples

Embodiment 1

[0034]Dry crush the peeled peanuts with a stone mill, weigh 130kg and add it to an electric heating type 1000L biochemical reactor, then add 650L tap water, mix well, adjust the pH to 9.5 with 2mol / L NaOH, and carry out alkaline extraction at 60°C for 30 minutes; Add Alcalase alkaline protease, the amount of enzyme added is 1.5mL / 100g protein, enzymatically hydrolyze at 60°C for 5h, heat up to 80°C to inactivate the enzyme for 15min; then use a three-phase separator to separate the three phases of the enzymatic hydrolysis system to obtain clear oil I Three parts, oil-water mixture and slag; the obtained oil-water mixture is separated by a disc centrifuge to obtain two parts, one part is oil phase and emulsion, and the other part is oily hydrolyzate. The oil phase and the emulsion are left to stand to obtain clear oil II and the emulsion, wherein the emulsion is demulsified by freezing and thawing to obtain the demulsified oil. The oil-containing hydrolyzate is disc-centrifuged...

Embodiment 2

[0041] Dry crush the peeled peanuts with a stone mill, weigh 150kg and add it to an electric heating 1000L biochemical reactor, then add 750L tap water, mix well, adjust the pH to 8.5 with 2mol / L NaOH, and carry out alkaline extraction at 60°C for 30 minutes; Add Alcalase alkaline protease, the amount of enzyme added is 1.5mL / 100g protein, enzymatically hydrolyze at 60°C for 8h, heat up to 80°C to inactivate the enzyme for 15min; then use a three-phase separator to separate the three phases of the enzymatic hydrolysis system to obtain clear oil I Three parts, oil-water mixture and slag; the obtained oil-water mixture is separated by a disc centrifuge to obtain two parts, one part is oil phase and emulsion, and the other part is oily hydrolyzate. The oil phase and the emulsion are left to stand to obtain clear oil II and the emulsion, wherein the emulsion is demulsified by freezing and thawing to obtain the demulsified oil. The oil-containing hydrolyzate is disc-centrifuged aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com