Water-shutoff method for sealing gas well effluent section by combination of incline cement and gas injection compression

A gas injection and section technology, which is applied in earth-moving drilling, sealing/isolation, wellbore/well components, etc., and can solve problems such as curing problems, inability to fill pores, and inability to plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further have a deeper, clear and detailed understanding and understanding of the structure, use and characteristics of the present invention, a preferred embodiment is now given, and the details are as follows in conjunction with the drawings:

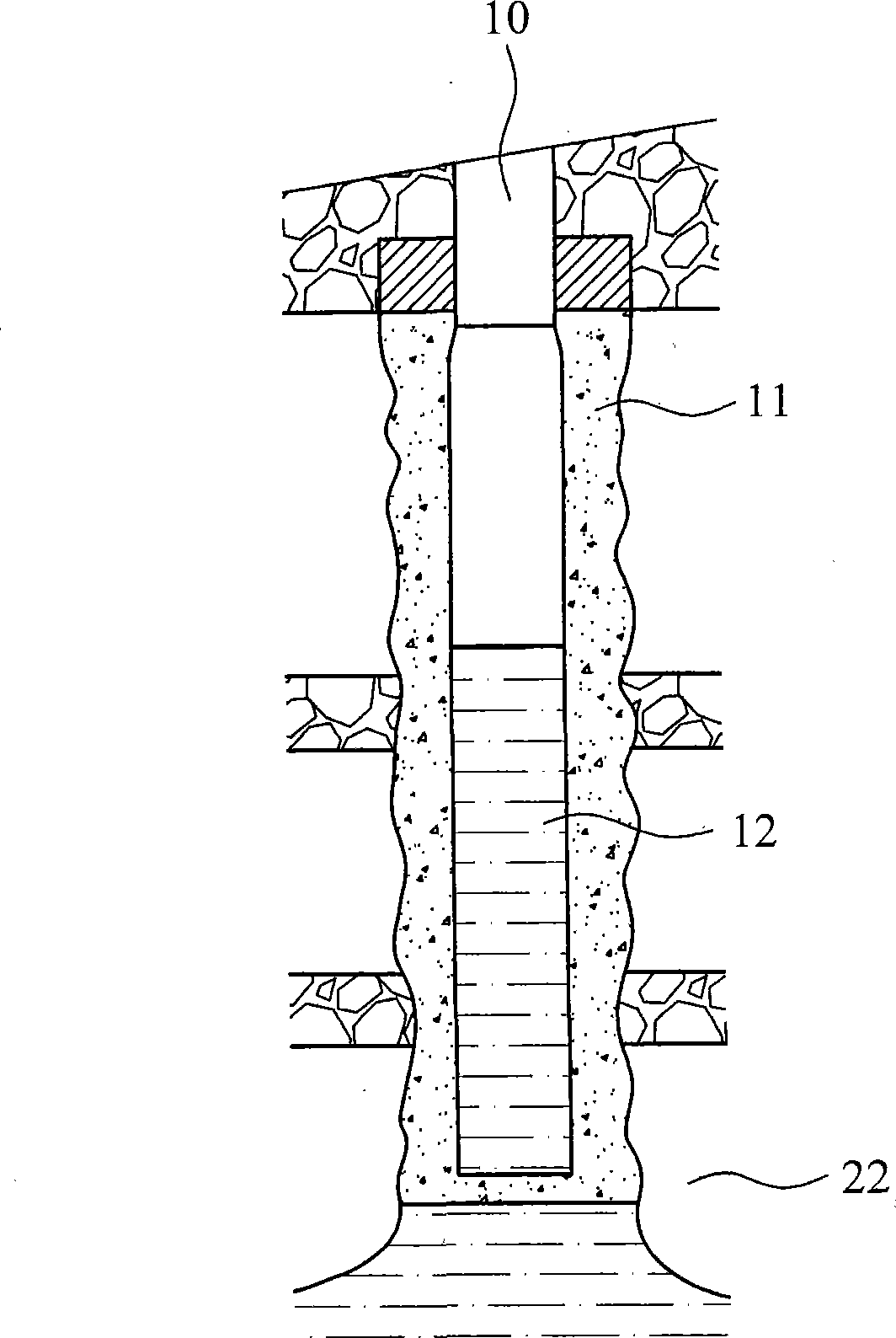

[0039] See first figure 1 , after the production of the gravel-packed production well 10, due to the rise of the gas-water interface, the accompanying water is also sucked out while the gas is produced. From the illustrated embodiment, the above-mentioned gravel-packed production well 10 drills through three layers of oil and gas layers, from top to bottom The bottom is the first oil and gas production layer 20, the second oil and gas production layer 21 and the third oil and gas production layer 22, and the impermeable layers between the above production layers are shale layers. In the third oil and gas production layer 22, it is clearly seen that the water cone rises into the gravel-filled production well 10, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com