Outdoor equipment for load driving apparatus and air conditioner, and load driving method

A technology of load driving and driving method, which is applied in the direction of AC motor control, refrigerator, heating method, etc., can solve problems such as inappropriate power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

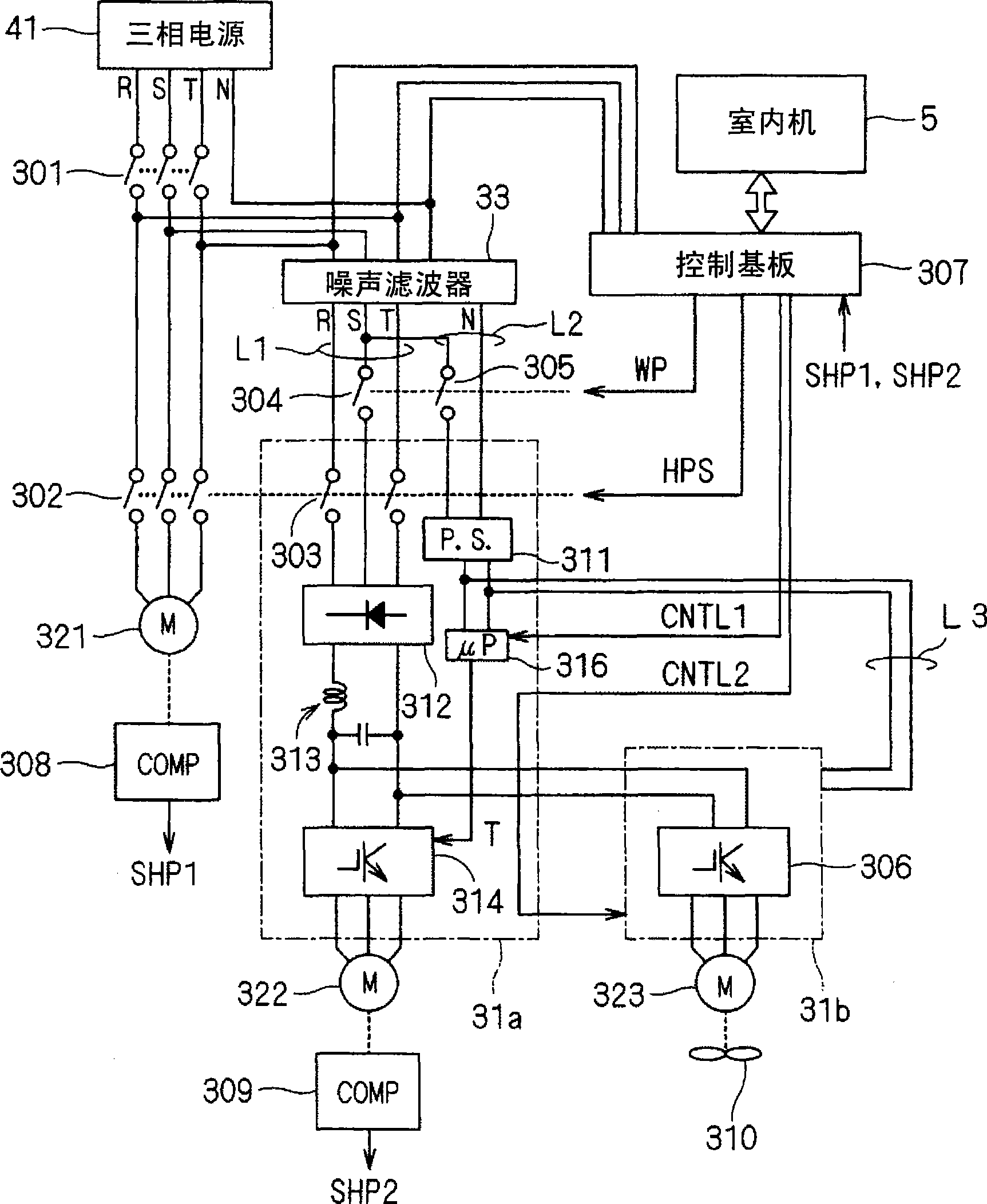

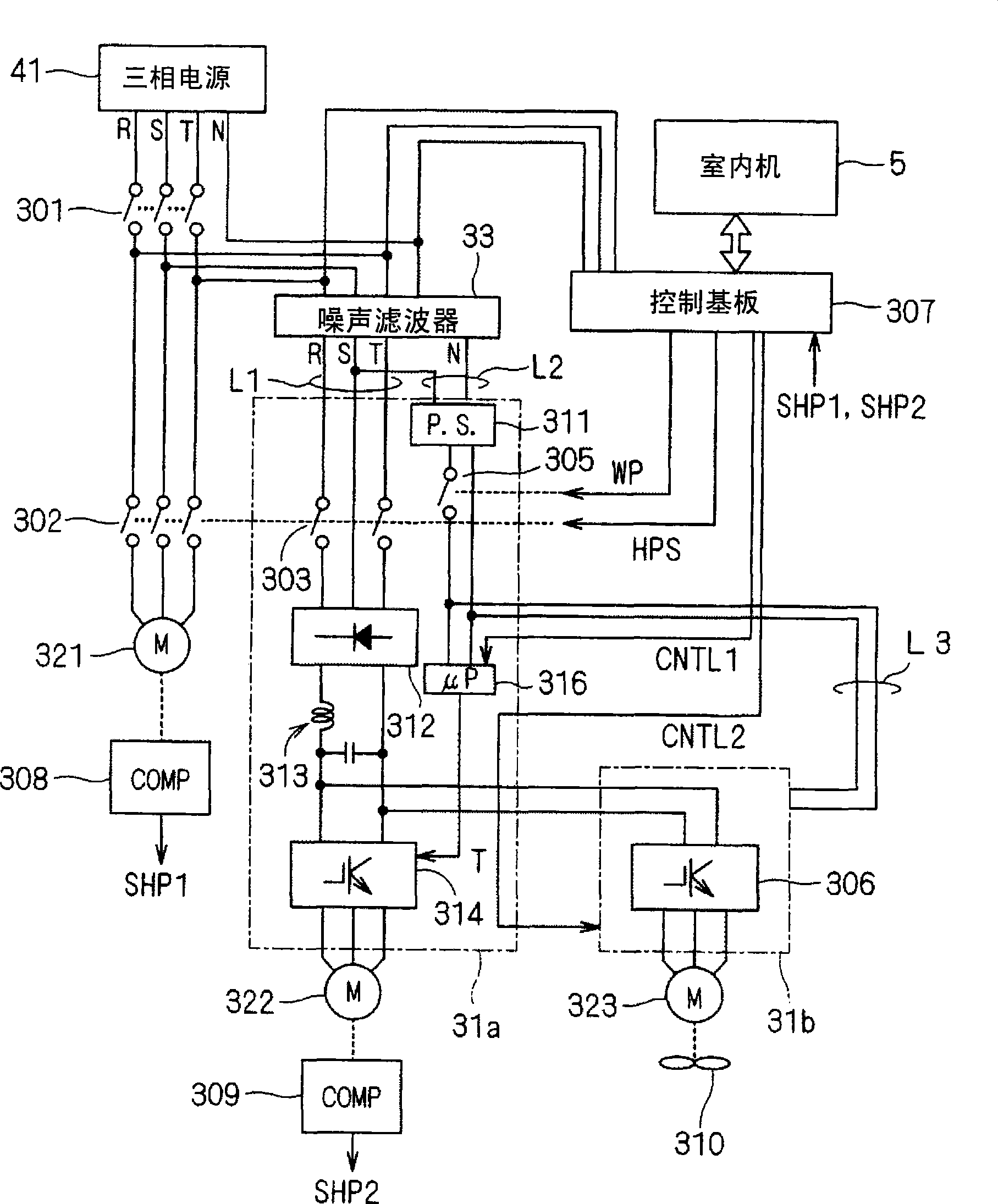

[0068] figure 1 It is a circuit diagram illustrating the configuration of an embodiment of the present invention. exist Figure 6 The structure shown and figure 1 In the shown structure, the same code|symbol is attached|subjected to the same component.

[0069] and Figure 6 The main difference of the shown structure is that: the control switch 305 connected to the output side of the power switch 301 and turned on / off by the switching command WP is provided; and the switching command WP is output from the control board 307 .

[0070] More specifically, the control switch 305 is located between the noise filter 33 and the power input 311 of the compressor driver 31a, and supplies / shuts off electric power to the compressor driver 31a.

[0071] In this embodiment, as the power line group L2 connected to the power supply input 311 in the compressor driver 31a, neutral point N and S-phase power lines are used, and the conduction of one S-phase power line in the power line group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com