Transitional rolling bed with electric elevating apparatus for front axle end head

A lifting device and transition roller technology, which is applied in the direction of transportation and packaging, conveyor objects, roller tables, etc., can solve the problems of difficult manufacturing, large structure occupation space, and insufficient compactness of movement, etc., to achieve excellent durability and compact overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

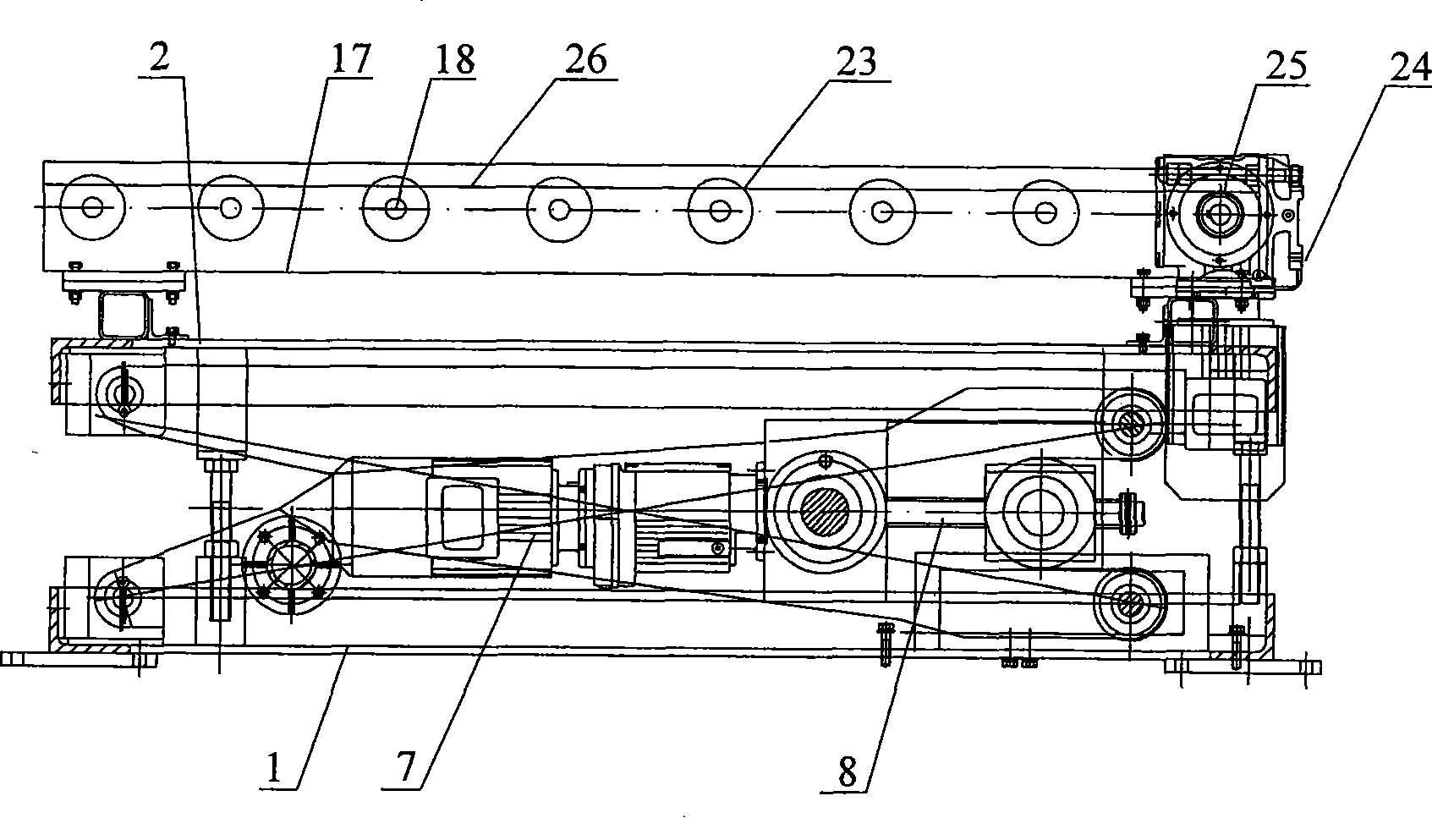

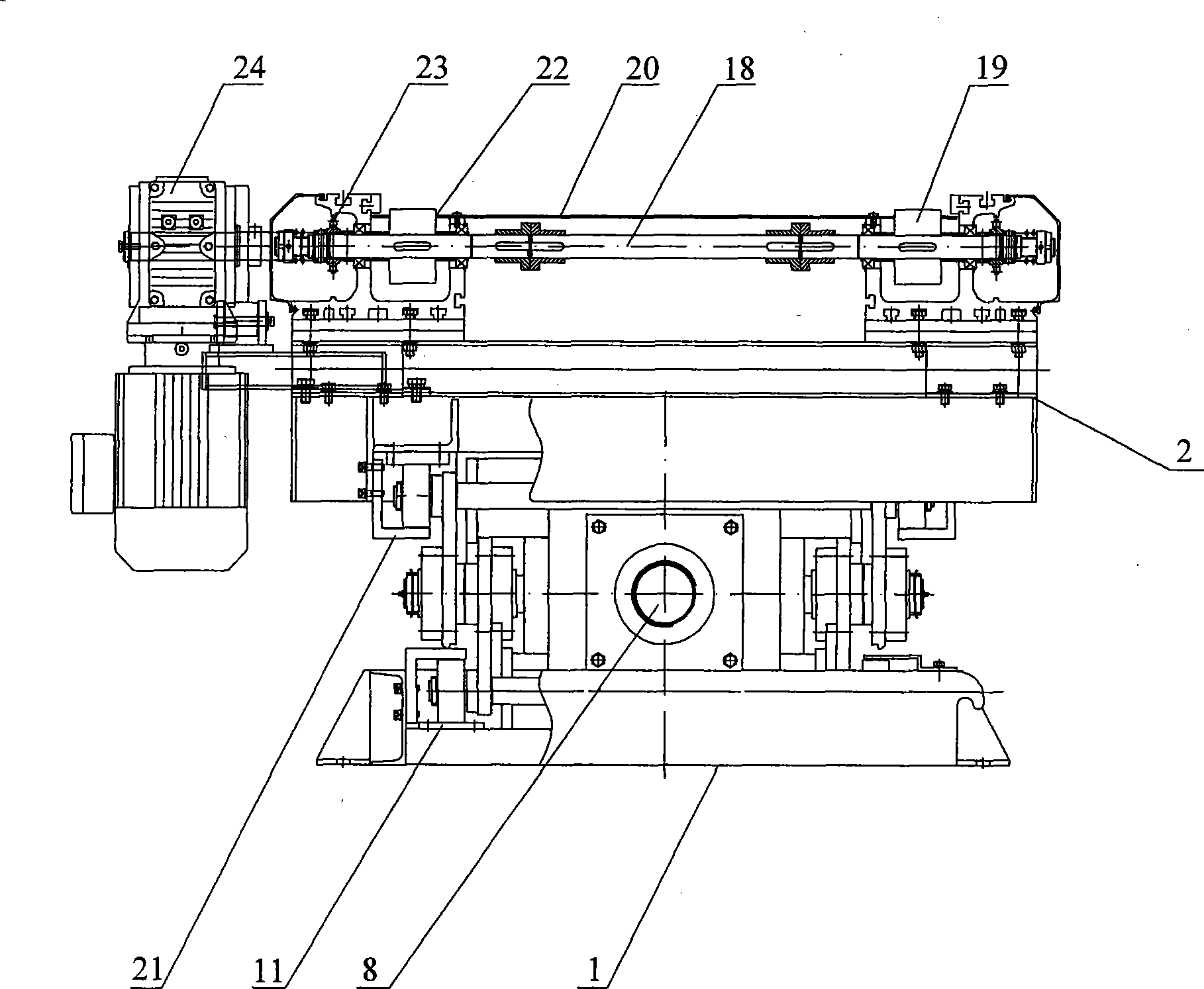

[0016] As shown in the figure: the present invention mainly consists of base plate 1, installation top plate 2, first driving arm 3, second driving arm 4, first roller 5, second roller 6, driving motor 7, screw mandrel 8, screw mandrel nut 9 , mounting seat 10, lower rail 11, first mounting part 12, second mounting part 13, first push rod 14, second push rod 15, main shaft 16, roller bed frame 17, roller shaft 18, roller 19, cover Plate 20, upper slide rail 21, groove body 22, transmission sprocket wheel 23, roller bed motor 24, drive sprocket wheel 25 and transmission chain 26 etc. are formed.

[0017] The present invention includes installing the fixed roller bed base frame 17 on the top plate 2, erecting a number of roller shafts 18 which are arranged parallel to the roller bed frame 17 and connected to it in rotation. There is a cover plate 20, and a groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com