Seal structure for tank periscopic lens

A technology of sealing structure and sight glass, used in telescopes, optics, instruments, etc., can solve the problems of large resistance torque and short service life of the peripheral sight glass, and achieve the effects of long service life, small resistance torque and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained in conjunction with the drawings:

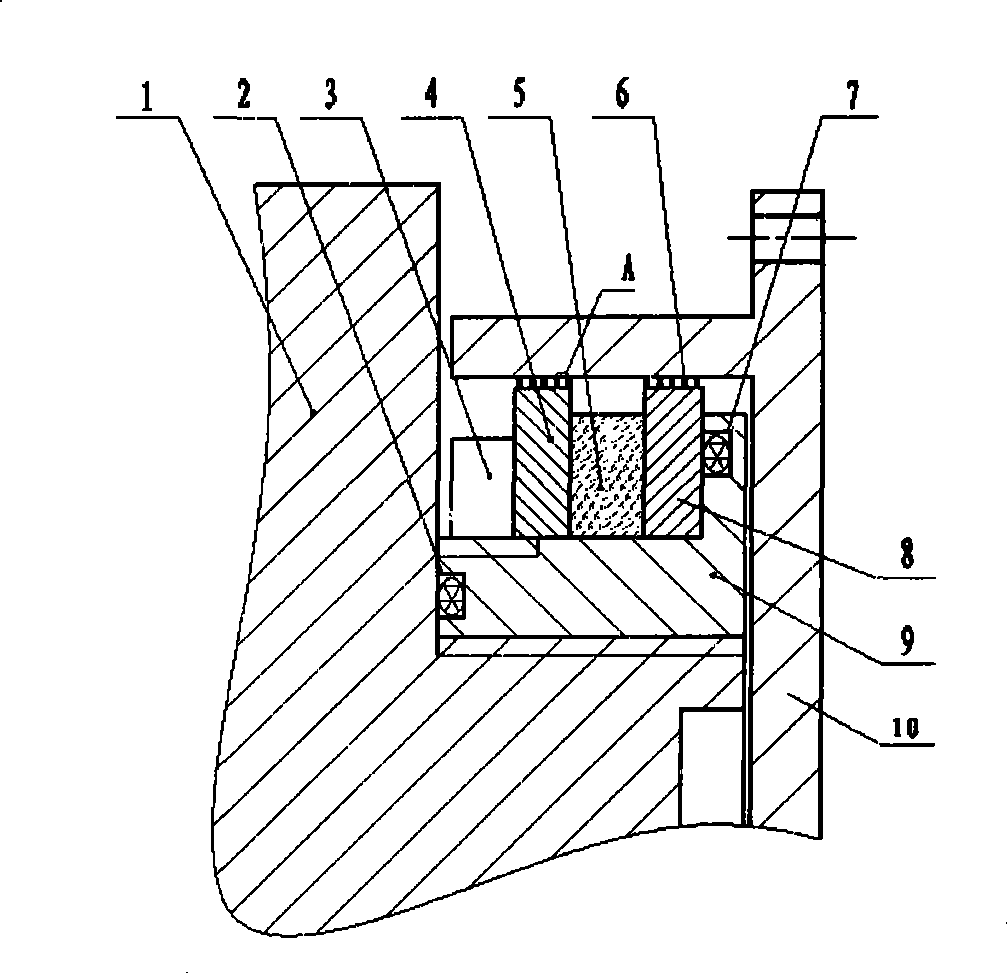

[0016] The sealing structure of the tank mirror, see figure 1 .

[0017] Put the first "O" ring 2 into the annular groove 12 on the small-diameter end of the non-magnetic sleeve 9, the second

[0018] The "O" ring 7 is inserted into the annular groove 13 on the inner surface of the large diameter end of the non-magnetic conductive sleeve 9;

[0019] Insert the right pole shoe 8, the permanent magnet 5 and the left pole shoe 4 from the small diameter end of the non-magnetic sleeve 9 in sequence, and use the screw connection of the nut 3 and the small diameter end of the non-magnetic sleeve 9 to lock the above three parts in the non-magnetic sleeve. On the magnetic sleeve 9, the non-magnetic sleeve 9 is threadedly connected with the azimuth shaft 1;

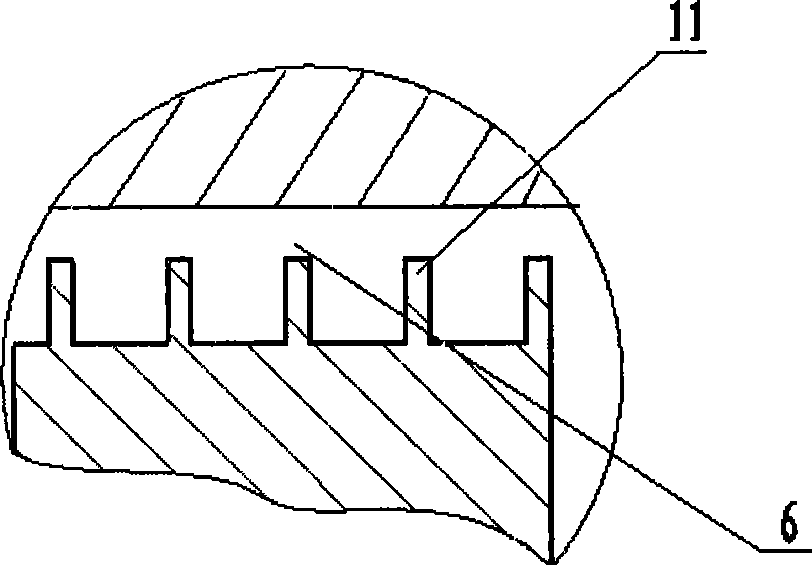

[0020] The upper reverse head 10 is sleeved on the right pole shoe 8 and the left pole shoe 4 assembled above, and forms a sealing gap 6, see f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com