Seal structure design method for narrow sealing plane box parts with complex shape

A linear sealing, sealing plane technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., to achieve the effect of easy implementation, good effect, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

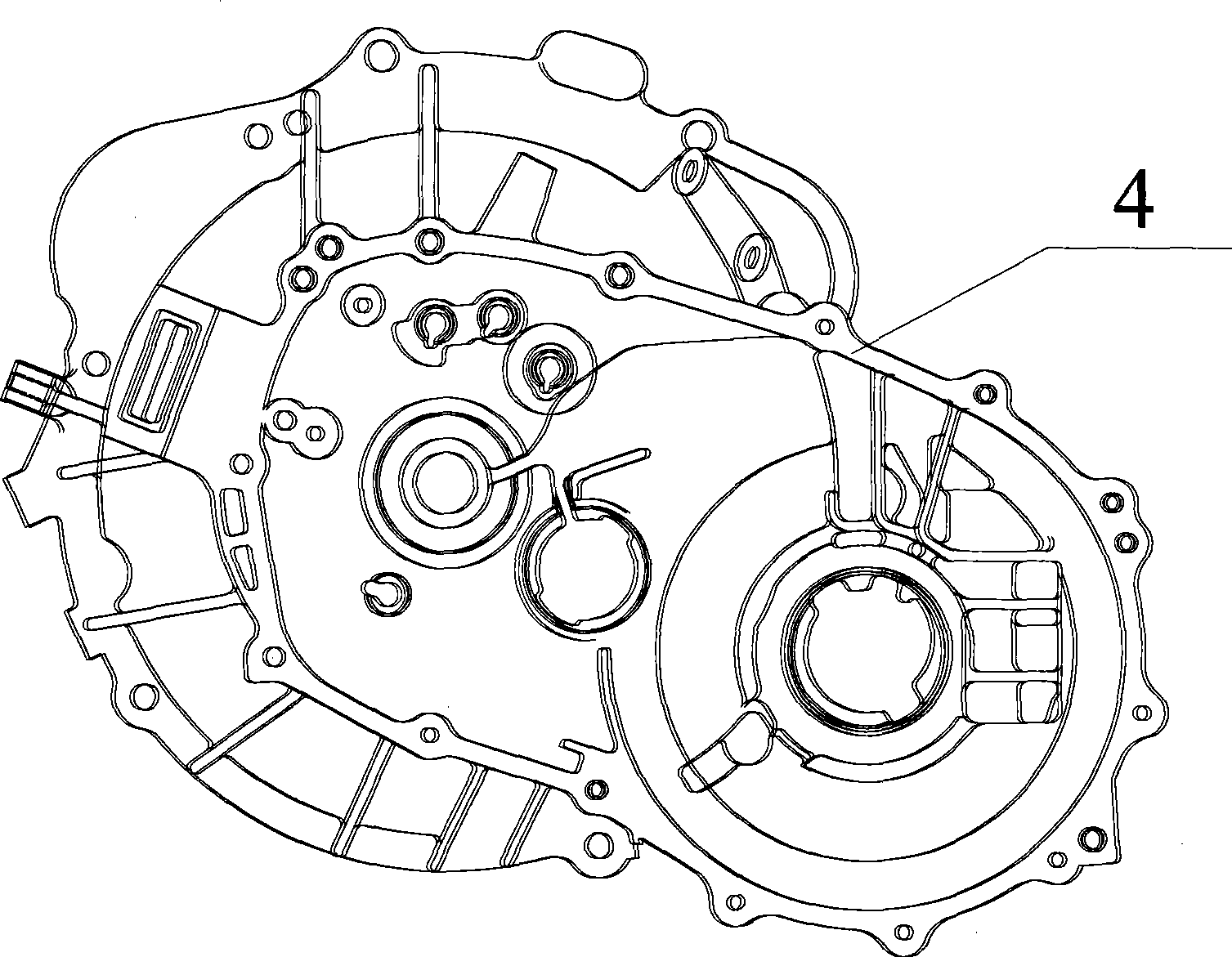

[0025] The present invention makes two improvements to the standard O-ring sealing technology, so as to meet the needs of complex track and narrow plane sealing.

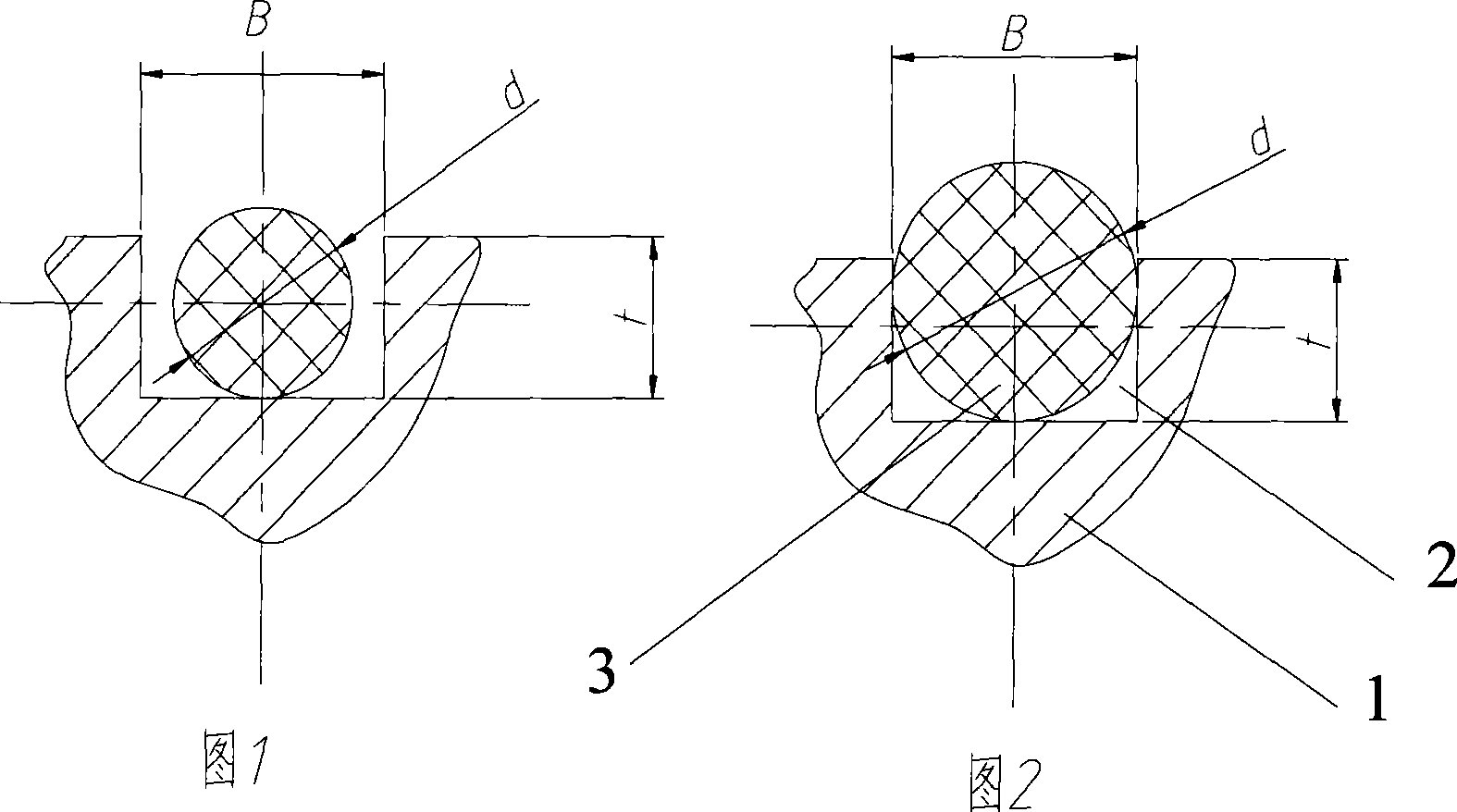

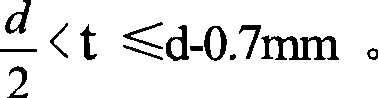

[0026] 1. Improved design of the groove size of the O-ring. Figure 2. In order to achieve the sealing accuracy of the narrow plane with complex tracks, the groove width dimension of the sealing groove 2 where the O-ring 3 is placed is improved, and the depth t of the groove remains unchanged, and the standard depth is still used. The design formula of the groove width B is: B=(1+3.5%~1+4.5%)d, where d is the cross-sectional diameter of the O-ring.

[0027] 2. Improved design of the actual length of the O-ring. Since the width of the sealing groove has changed, and the O-ring is an elastic material, its radial elongation is transferred to the length elongation along the center line of the O-ring under the action of sealing pressure, then the standard O-ring The length of the sealing ring is obviously too long in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com