Micro optical fibre voltage sensor based on ring micro-cavity

A voltage sensor, annular microcavity technology, applied in the process of producing decorative surface effects, microstructure technology, microstructure devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

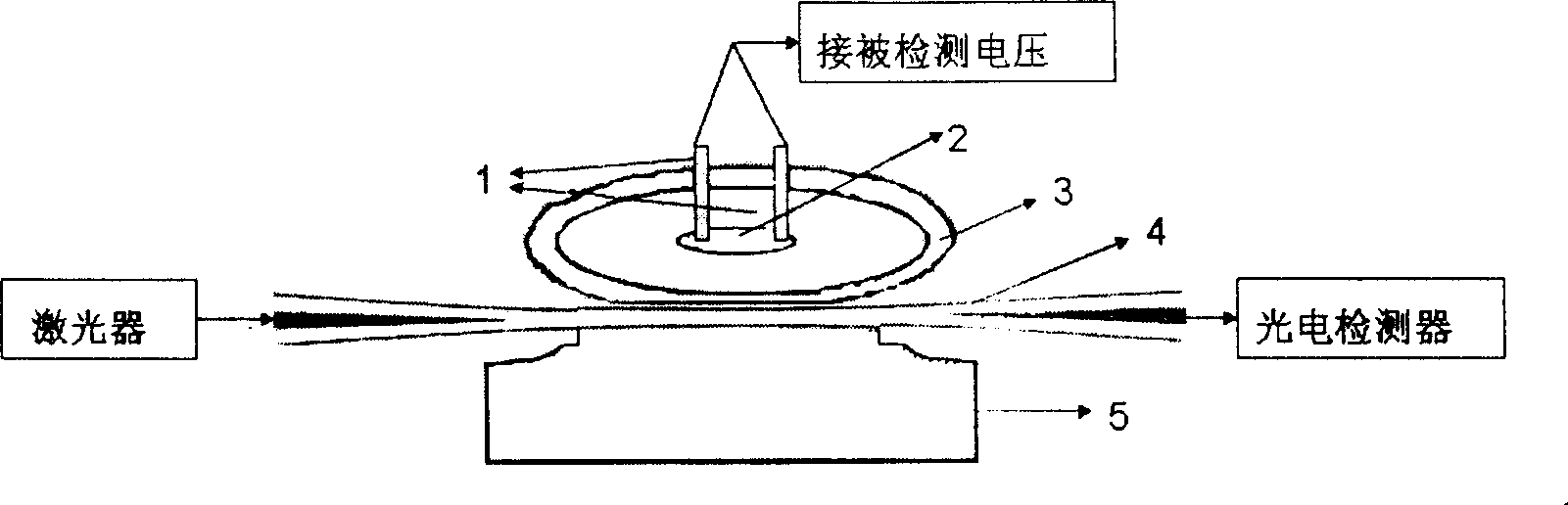

[0043] Such as figure 1 Shown schematically, a kind of micro-optical fiber voltage sensor based on the ring microcavity, the structure includes the planar ring microcavity 3 supported by the silicon column 5, and the tapered optical fiber 5 coupled with the planar ring microcavity 3, the middle part of the planar ring microcavity 3 An aluminum ohmic contact 2 is set on the microdisc, and two tungsten probes 1 are planted on the metal ohmic contact 2. The diameter of the annular microcavity in the above device is 60um--120um, the diameter of the ring is 5um--8um, and the silicon column The height of the tapered fiber is 30um--45um, the diameter of the tapered optical fiber is 1um--3um, the diameter of the ohmic contact is 20um--25um, the thickness is 0.1um, and the diameter of the probe is 10um--20um.

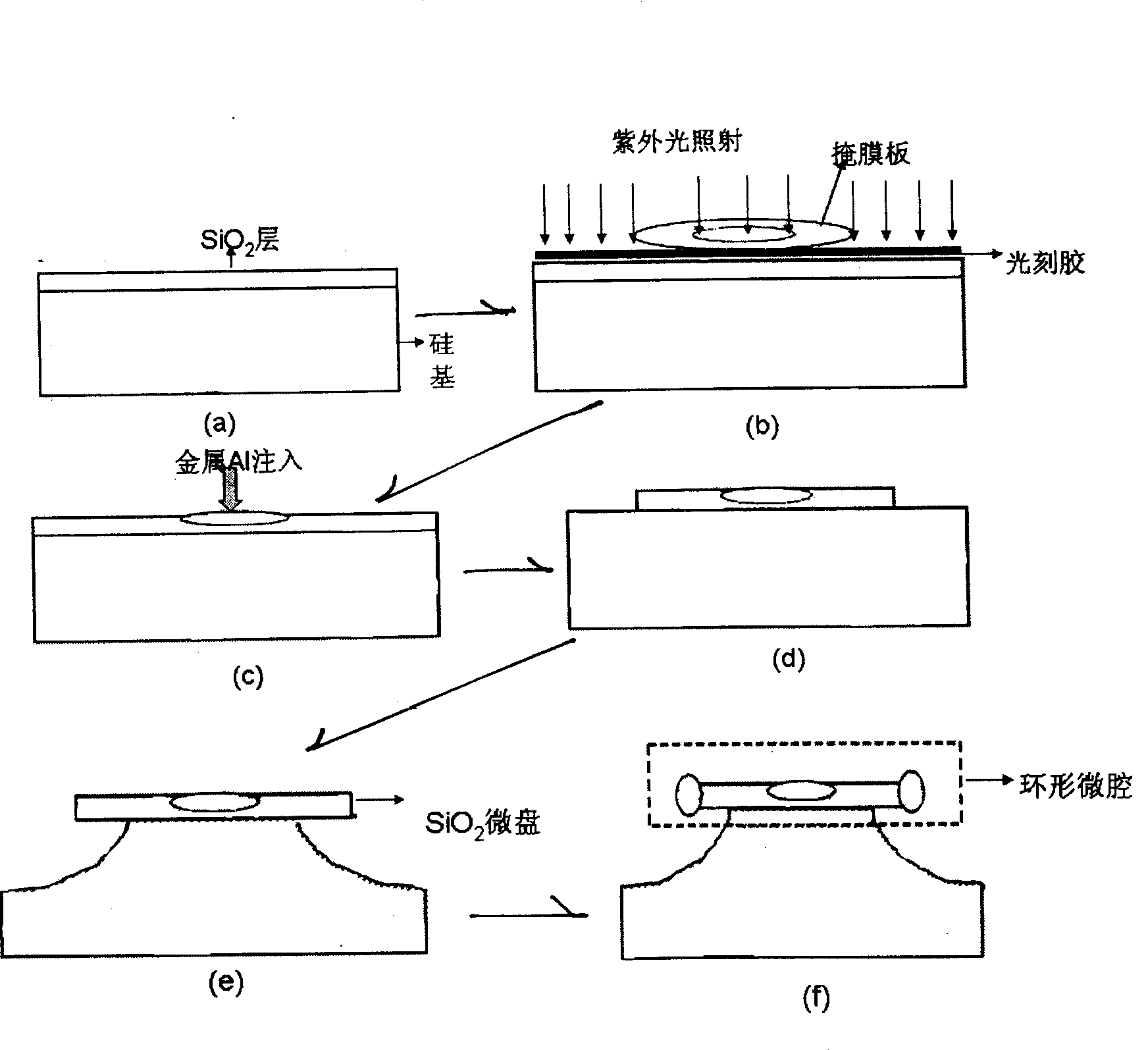

[0044] Such as figure 2 As shown, the processing method is, one, the making of annular microcavity,

[0045] 1. Thermally grow a silicon dioxide layer on a polished p-type hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com