Motor/pump assembly

A technology for motor pumps and motor shafts, which is applied in the direction of pumps, pump components, mechanical equipment, etc., can solve problems such as high cost, and achieve the effects of simple methods, simplified assembly, and compensation for assembly tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

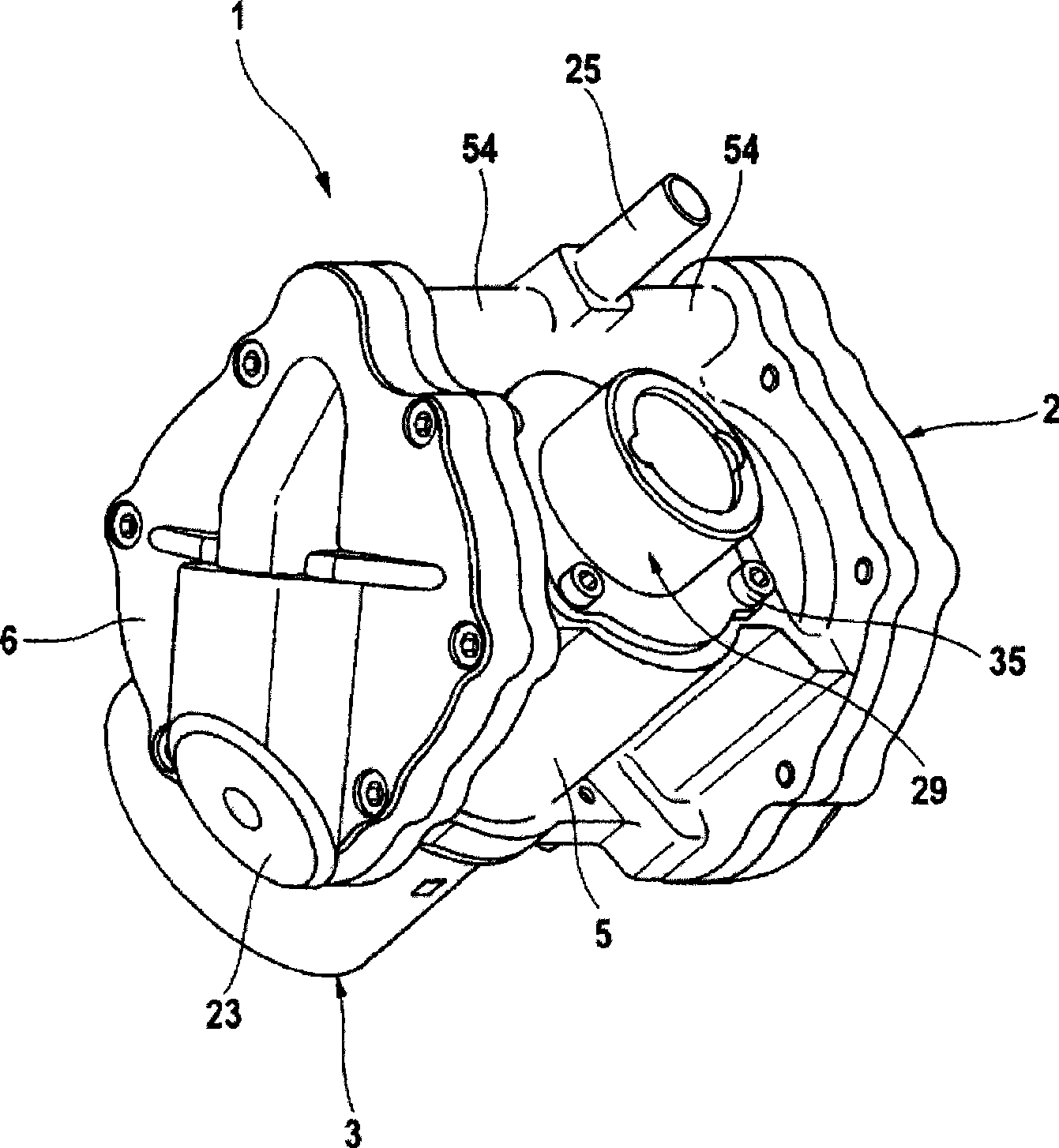

[0050] figure 1 A first embodiment of an electric motor-pump unit 1 according to the invention is shown in perspective view, for example for a brake actuator of a motor vehicle brake system equipped with a pneumatic brake booster (not shown) Provide vacuum. The motor-pump assembly 1 comprises a pump 2 with a pump housing 5 and an electric motor 3 driving the pump 2 , which can be designed as a DC motor, for example.

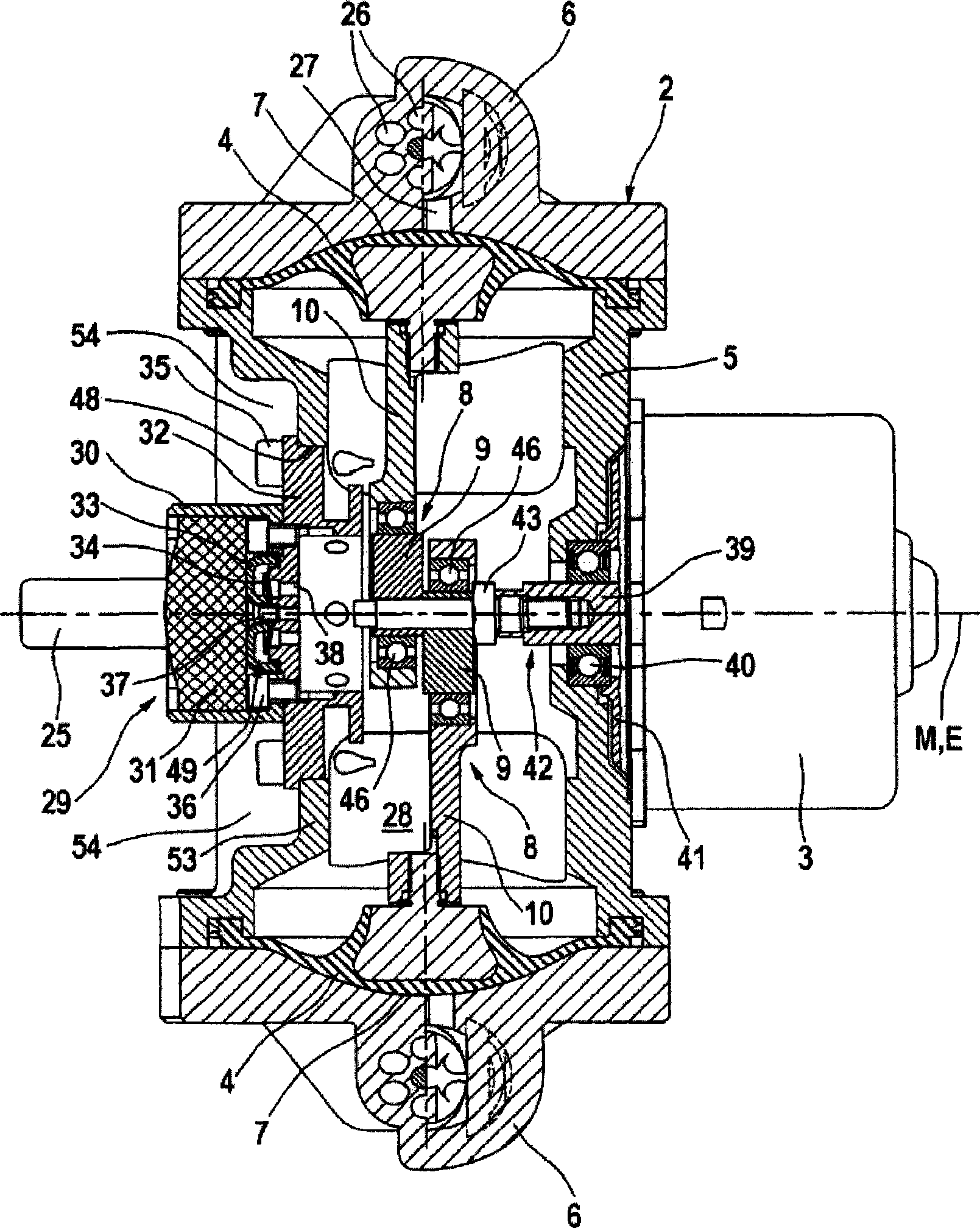

[0051] In particular, the motor-pump unit 1 is shown in a longitudinal section along a first plane. figure 2 It can be seen that the pump 2 is designed as a double-diaphragm pump with two opposing working diaphragms 4 which are each stretched between the pump housing 5 and the working chamber cover 6 and thereby delimit the working chamber 7 . The working diaphragms 4 can be moved in opposite directions by means of a crank drive 8 , which comprises an eccentric body 9 and a connecting rod 10 for each working diaphragm 4 .

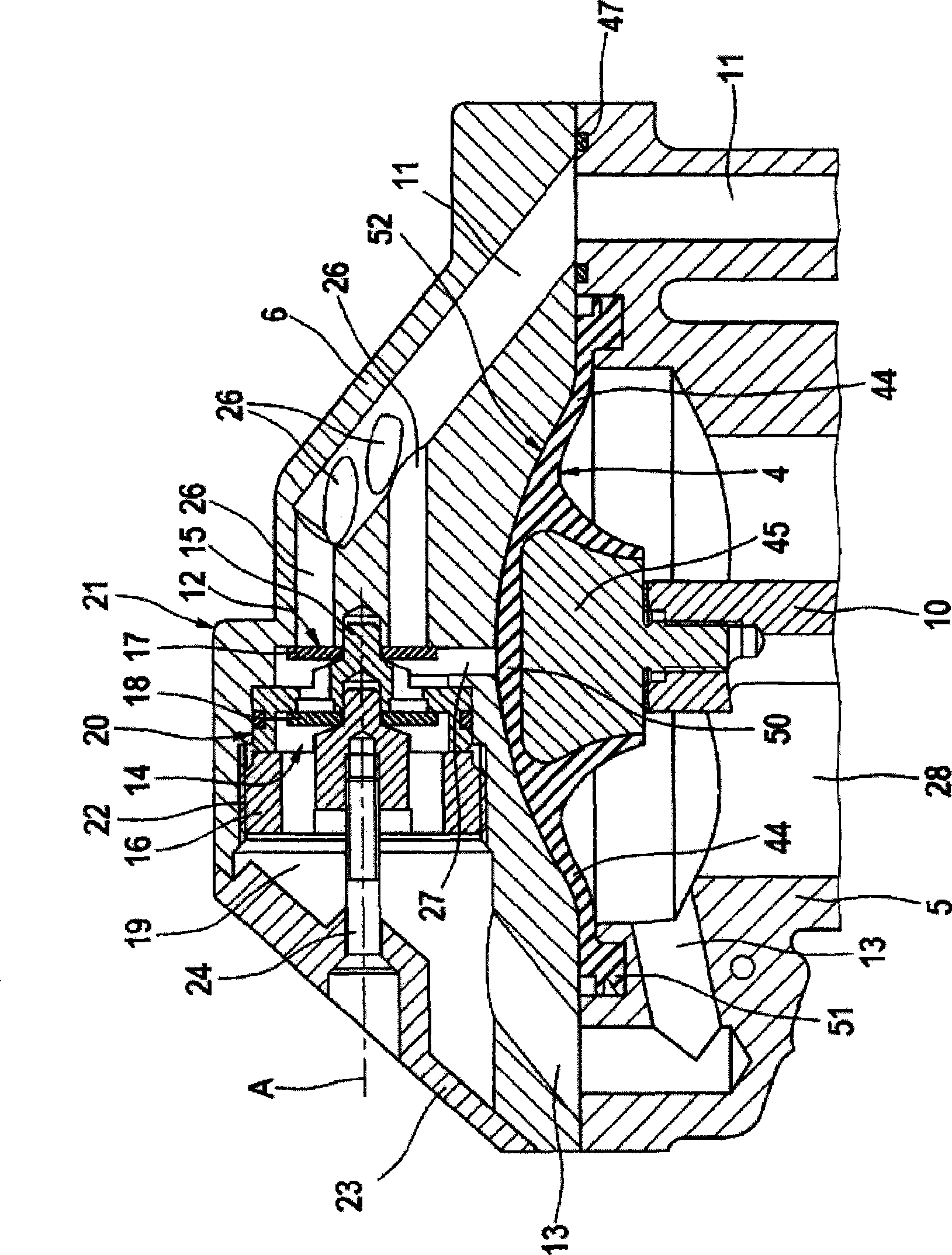

[0052] By showing a partial view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com