Solar energy linkage rod sun-following electricity generation plant

A technology of solar panels and solar energy, applied in the field of solar power station systems, can solve problems such as loss of solar energy, high power consumption, and increased equipment manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

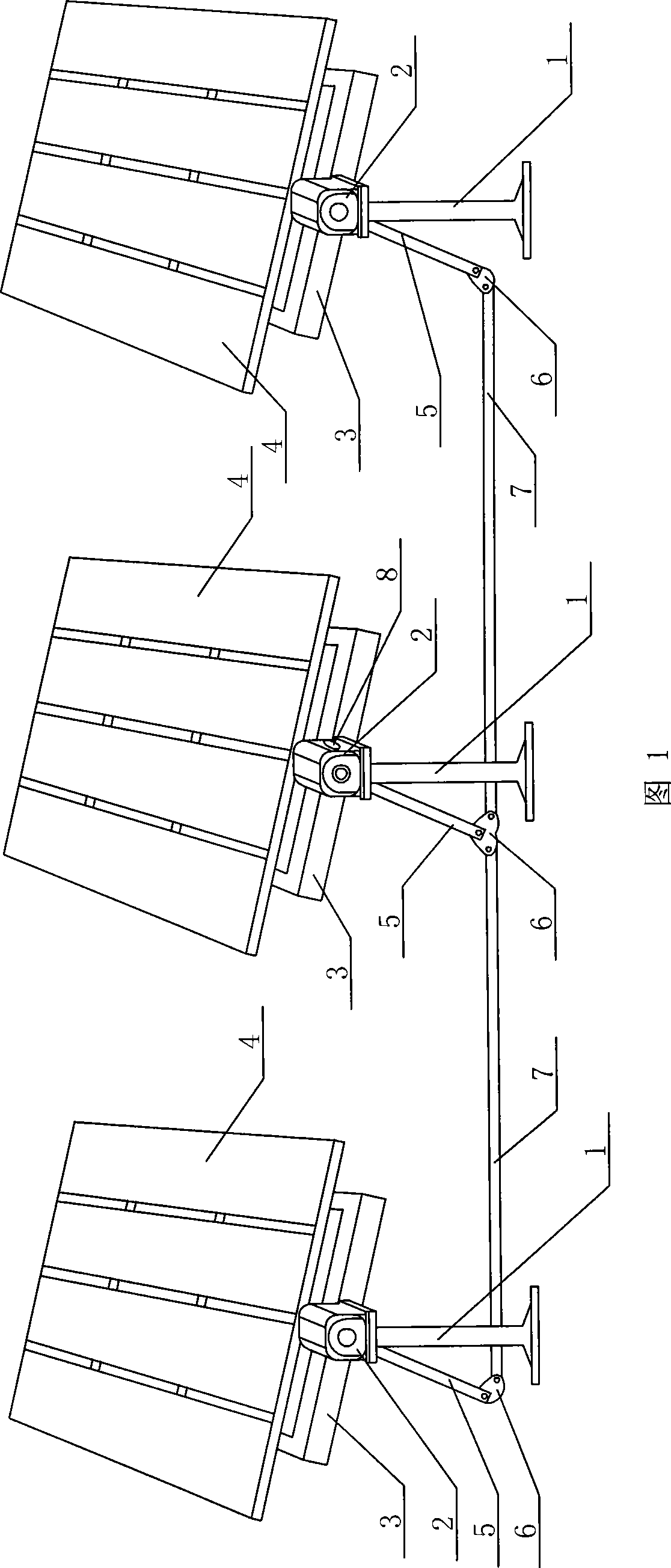

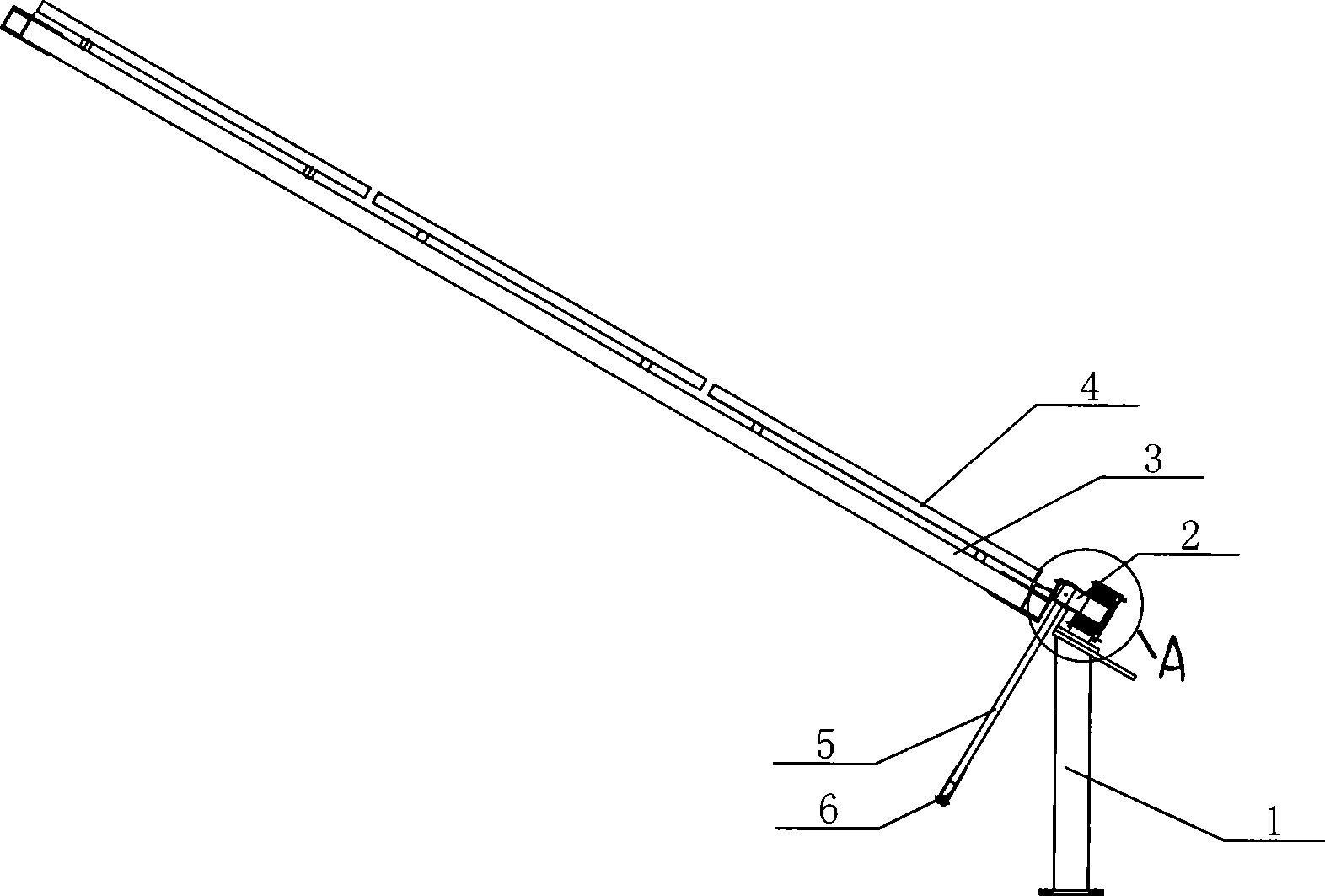

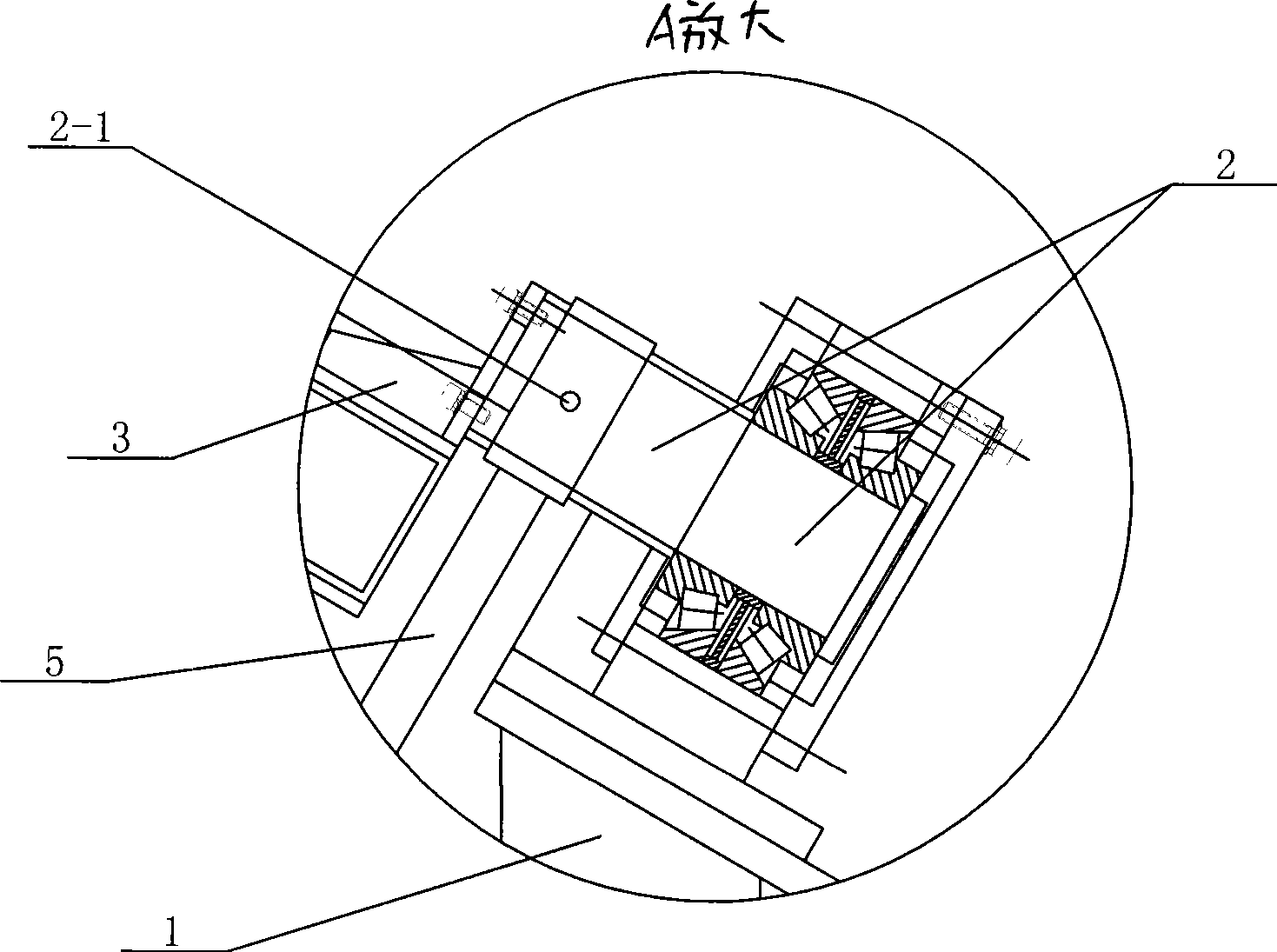

[0005] Referring to Figures 1-3, the present embodiment adopts the following technical scheme: it includes three supports 1, three support shafts 2, three solar panel supports 3, a plurality of solar panels 4, and each support support shaft 2 All are connected with a synchronous connecting rod 5, and the lower end of the synchronous connecting rod 5 is connected with one end of the cross bar 7 through the rotating device 6; a support shaft 2 is provided with a motor connection hole 8. The motor connecting hole 8 can be connected with a driving motor.

[0006] The upper end of the synchronizing link 5 is hinged to the support shaft 2, and a fixed pin 2-1 is arranged at the hinge. The fixed pin 2-1 can ensure that the synchronous connecting rod 5 follows the rotation of the support shaft 2 and rotates, thereby driving the cross bar 7 at the lower end of the synchronous connecting rod 5 to move, and the cross bar 7 can drive other synchronous connecting rods 5 to move synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com