Blowing and discharging fan

A technology for supplying and exhausting air and motors, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., and can solve problems such as noise, pressure fluctuations, and reduced air supply capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

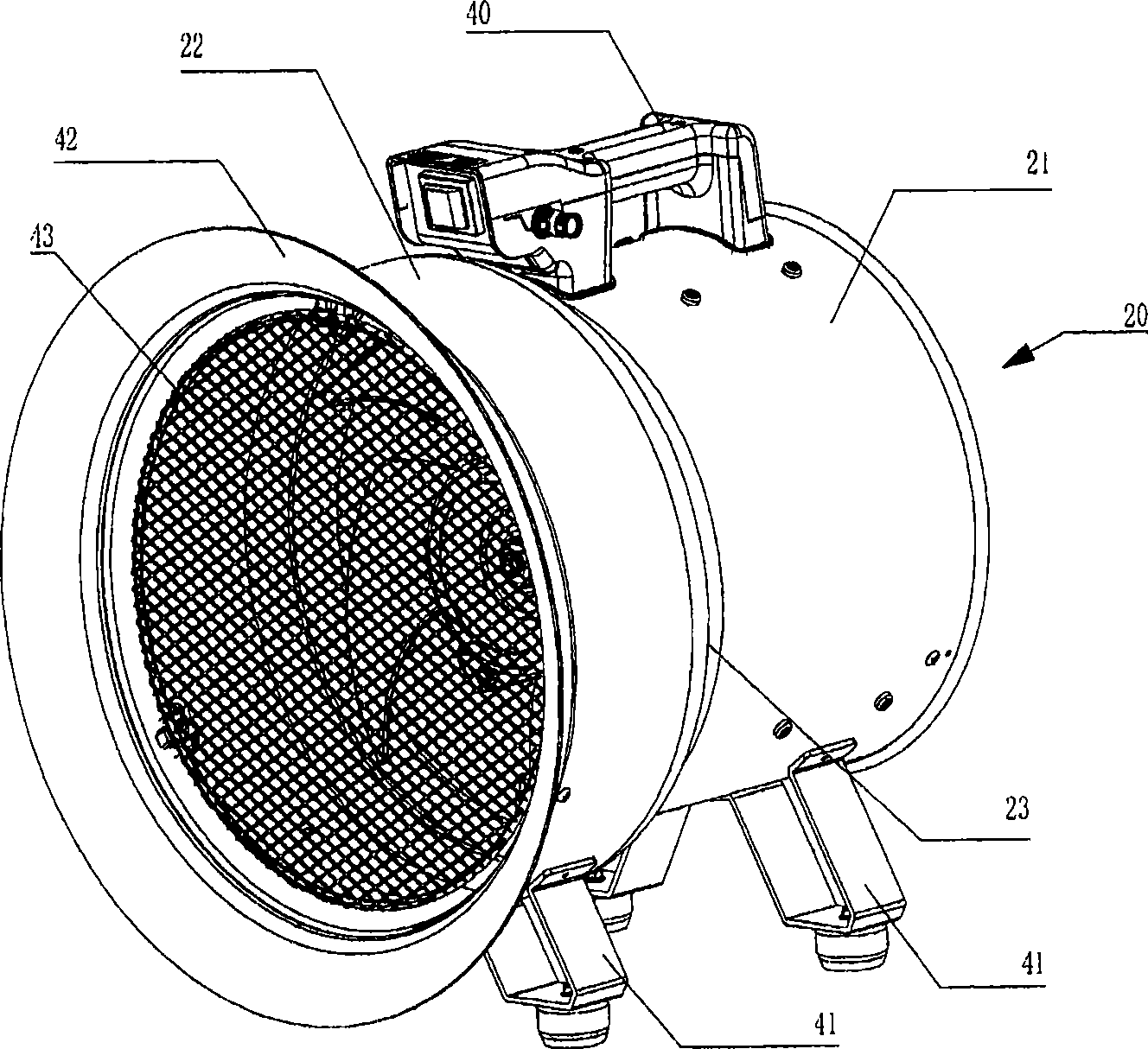

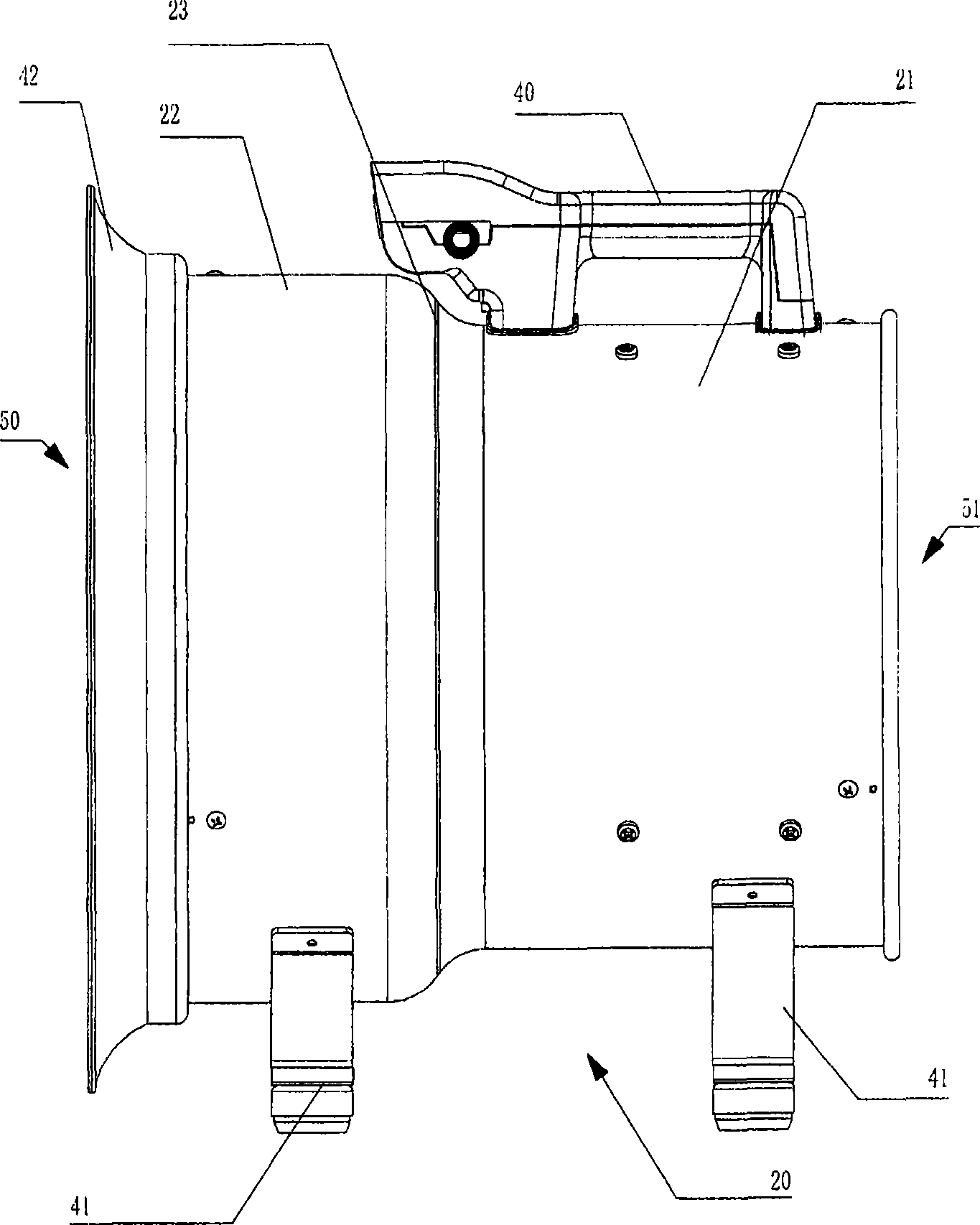

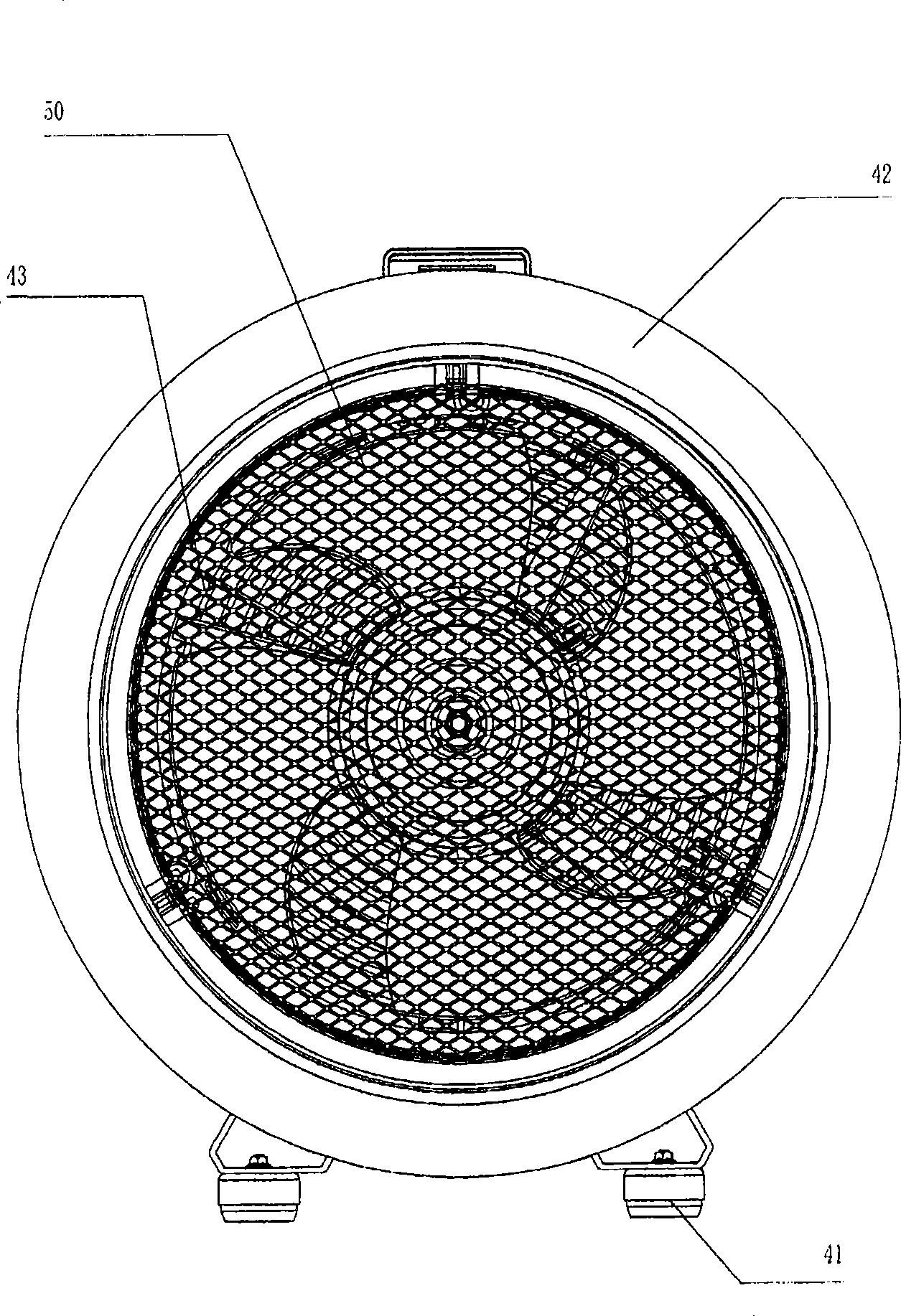

[0028] figure 1 is a perspective view of the present invention, figure 2 is the main view, image 3 is the left view, Figure 4 is the right side view, Figure 5 It is a front view in which the casing 20 is cut away so that the internal structure can be observed.

[0029] Such as figure 1 , figure 2 As shown, the casing 20 of the air blower of the present invention is composed of a large-diameter expanded tube part 22, a diameter-reduced reduced-diameter tube part 23, and a small-diameter main tube part from the suction port 50 side toward the discharge port 51 side. 21 is continuously formed into a substantially cylindrical shape. Such as image 3 As shown in FIG. 22 , the bell mouth 2 is provided on the expanded tube portion 22 , and a mesh safety cover 43 capable of ventilation is provided on the suction port 50 . Additionally, if Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com