Honeycomb structure

A honeycomb structure, through-hole technology, applied in colloidal chemistry, colloidal chemistry, catalyst carrier, etc., can solve the problem of insufficient particle combustion and removal efficiency, achieve economical combustion and removal, reduce the rise and suppress pressure loss the rising effect of

Inactive Publication Date: 2011-12-21

IBIDEN CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] In addition, according to the method described in Patent Document 2, in the honeycomb structure in which the catalyst is supported on the through-hole walls, the efficiency of combustion and removal of fine particles is not sufficient, and there is room for further improvement for efficient purification of exhaust gas.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~3

[0194] The amount of the catalyst supported on the through-hole walls was set to the value shown in Table 2, a honeycomb fired body was produced, and the following tests were performed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

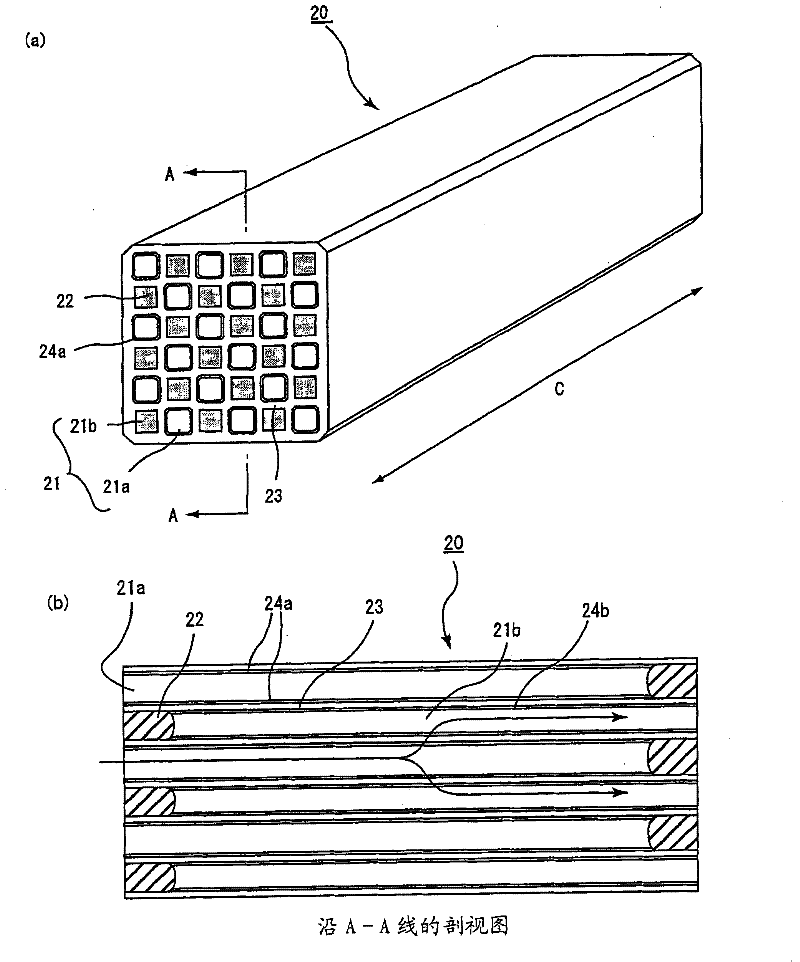

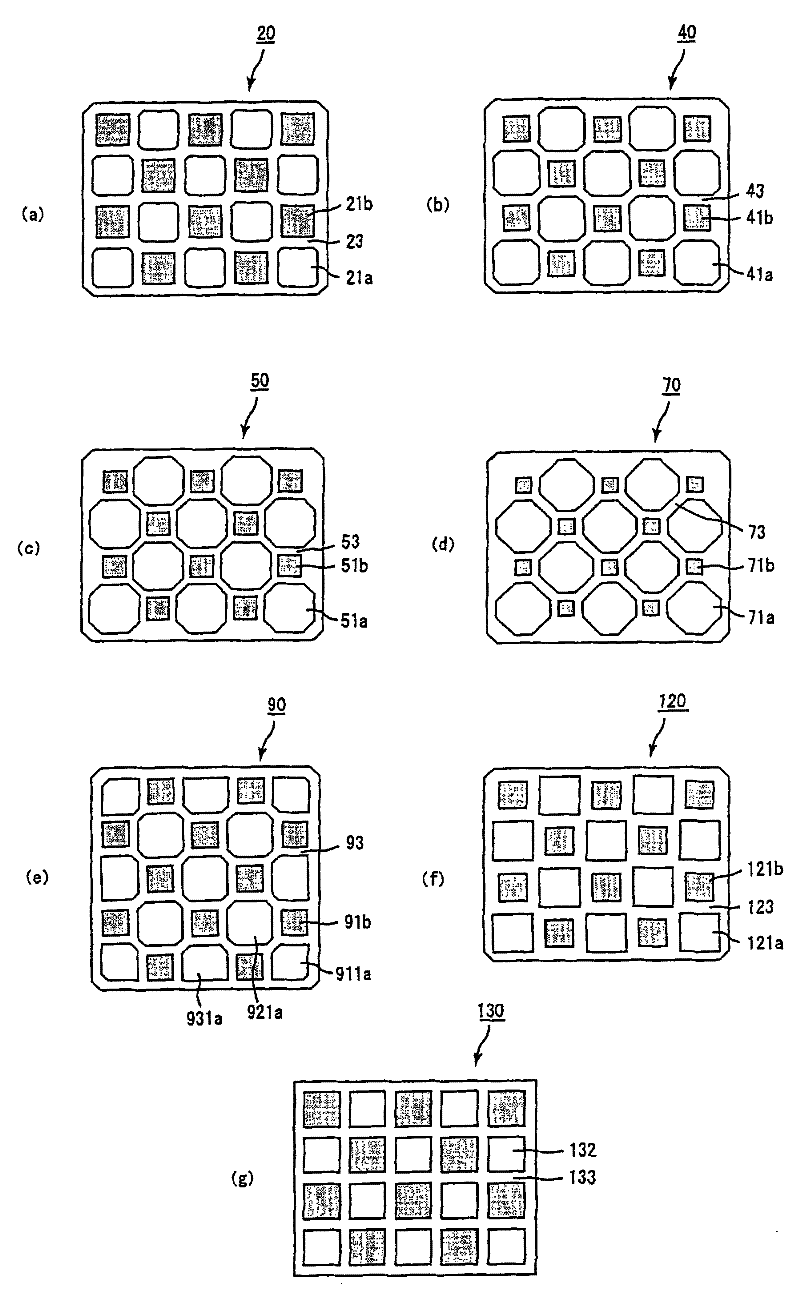

An object of the present invention is to provide a honeycomb structured body capable of keeping an amount of a supported catalyst to a low level, sufficiently burning and removing particulates, and suppressing an increase in a pressure loss. The pillar-shaped honeycomb structured body according to the present invention includes: a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween; a plug sealing either one of end portions of the cell; and a catalyst being supported on the cell wall, wherein the plurality of cells are composed of large-volume cells and small-volume cells, the large-volume cell has a larger cross-sectional area perpendicular to a longitudinal direction thereof than a cross-sectional area perpendicular to the longitudinal direction of the small-volume cell, the large-volume cell is sealed at one end portion of the honeycomb structured body, while the small-volume cell is sealed at the other end portion of the honeycomb structured body, and the catalyst is supported only on the cell walls forming the large-volume cells, or on both of the cell walls forming said large-volume cells and the cell walls forming said small-volume cells, and an amount of the catalyst supported on the cell walls forming the large-volume cells is larger per unit volume than that of the catalyst supported on the cell walls forming the small-volume cells.

Description

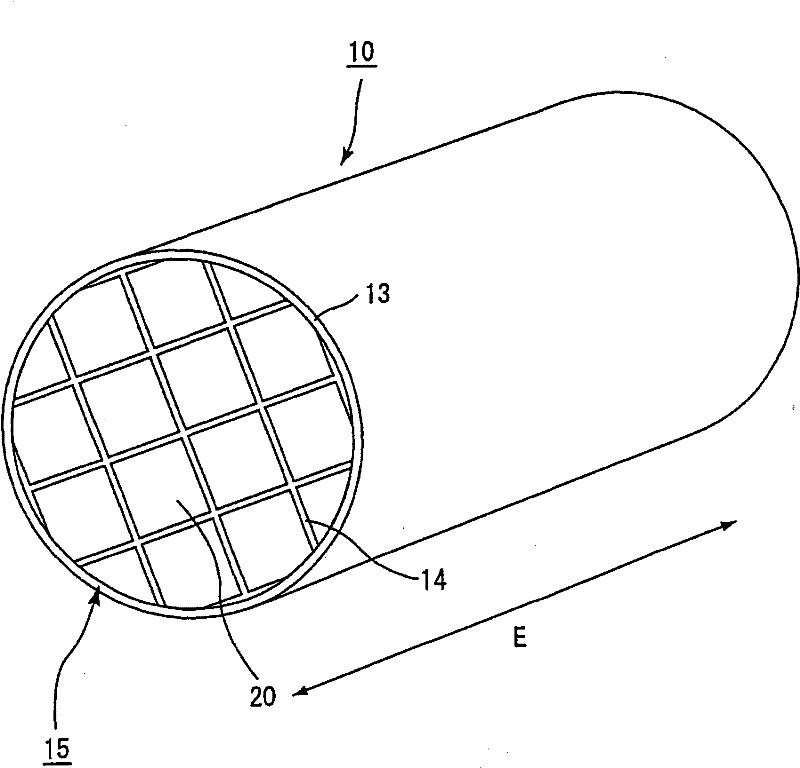

technical field [0001] The present invention relates to a honeycomb structure. Background technique [0002] Particulate matter (hereinafter, also simply referred to as particulate) contained in exhaust gas discharged from vehicles such as buses and trucks and internal combustion engines such as construction machines has recently become a problem because it is harmful to the environment or human body. [0003] Therefore, various honeycomb structures made of porous ceramics have been proposed as filters capable of trapping fine particles in exhaust gas and purifying exhaust gas. [0004] As such a honeycomb structure, known as Image 6 As shown, a plurality of through-holes 31 are separated in the longitudinal direction ( Image 6 (direction of arrow D in a)) columnar honeycomb structures 30 arranged in parallel. Such as Image 6 As shown in (b), either the end portion of the exhaust gas inflow side or the discharge side of the through hole 31 is sealed by the sealing materi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01D53/94B01D39/14B01D39/20B01D46/00B01J35/04F01N3/02

CPCF01N3/0222B01J35/04F01N2450/28B01D53/9454C04B2111/0081F01N3/035B01J23/83C04B38/0016F01N2330/30Y02T10/22B01J23/34Y10S55/30F01N3/2828F01N2330/34C04B38/0012Y10T428/24157Y02T10/12B01J35/57C04B35/00B01D53/94B01D39/14B01D39/20F01N3/02B01J35/56

Inventor 大野一茂国枝雅文

Owner IBIDEN CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com