Semi-automatic unloading apparatus for gas chamber

A semi-automatic and gas cabinet technology, which is applied to adjustable-capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as short time and lightning strike accidents, and achieve fast control and avoid lightning strike accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

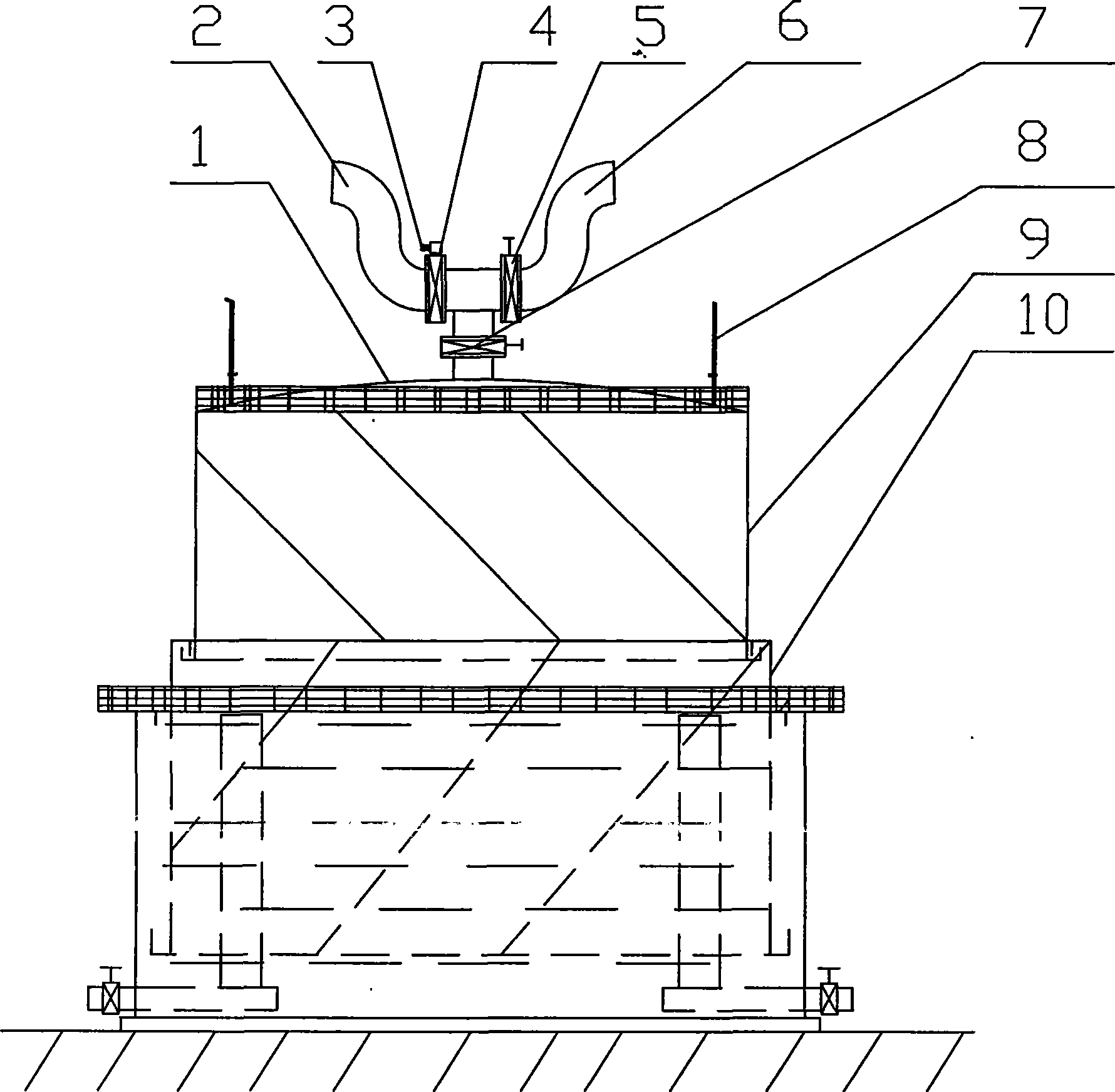

[0009] See attached figure 1 As shown, the present embodiment includes a gas cabinet first tower 9, a gas cabinet second tower 10, and a main vent valve 7. The flanges are respectively connected with at least two venting branch pipes 2 and 6. A pneumatic valve 4 with a gas pipe 3 is installed at the flange connection between the venting main pipe and one of the venting branch pipes 2. The venting main pipe is connected to the flange of the other venting branch pipe 6. A manual vent valve 5 is installed at the place. The gas cabinet top plate 1 is also connected with a manual venting small pipe 8 . The present invention has increased gas cabinet vent branch pipe 2 and 6 on the original structure of gas cabinet, manual vent valve 5, pneumatic valve 4 and trachea 3 and electromagnetic valve and control button with control pneumatic valve switch. When the gas cabinet suddenly rises rapidly, the instrument operator in the operating room of the gas building quickly puts the soleno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com