High-torsion universal joint structure

A universal joint and high torque technology, applied in the field of universal joints, can solve the problems that the second universal joint 80 is unusable, cannot effectively increase the torsion resistance, and the parts of the two pivot ears are easily deformed and damaged, so as to reduce deformation damage, increase service life, and increase torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

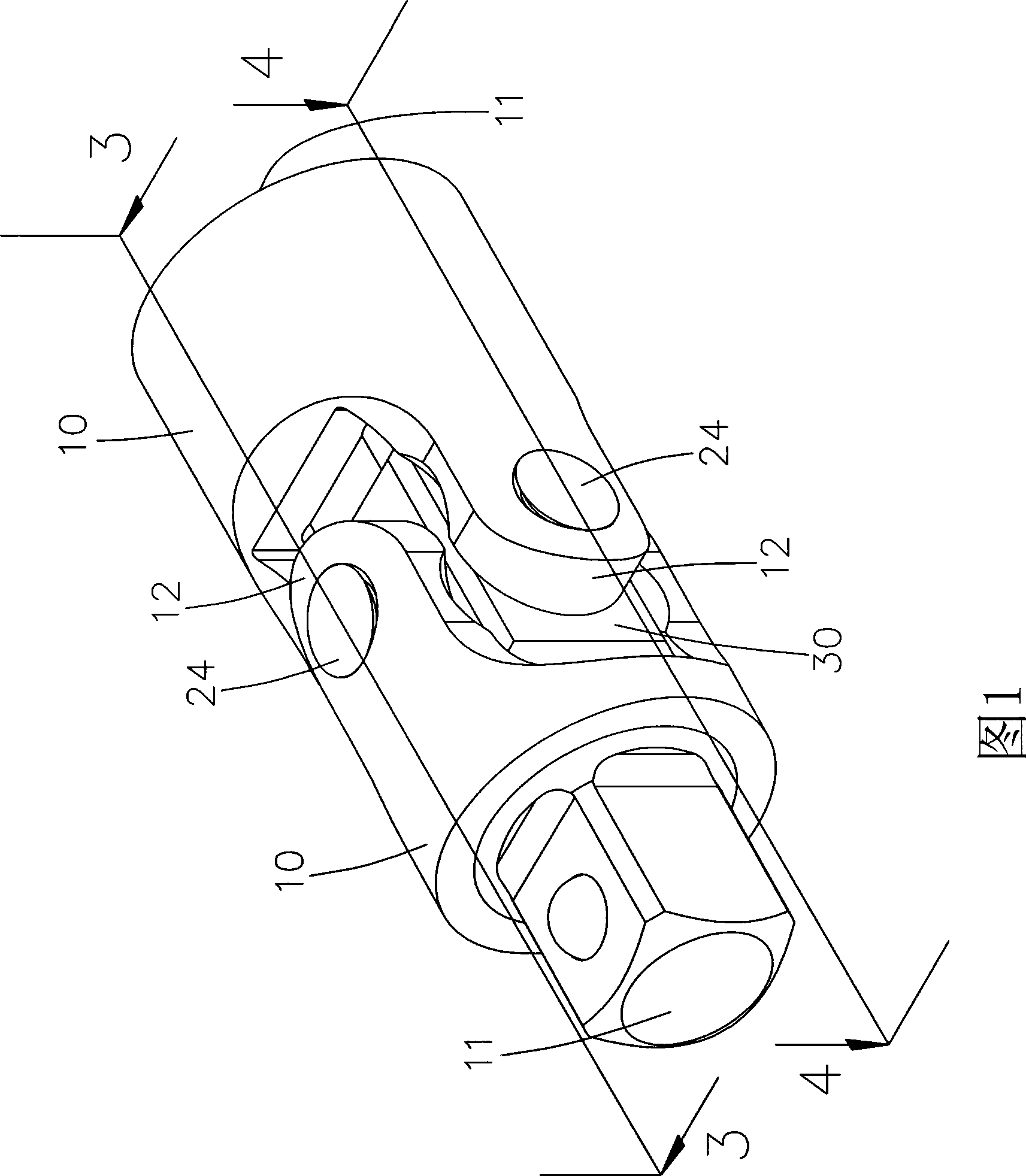

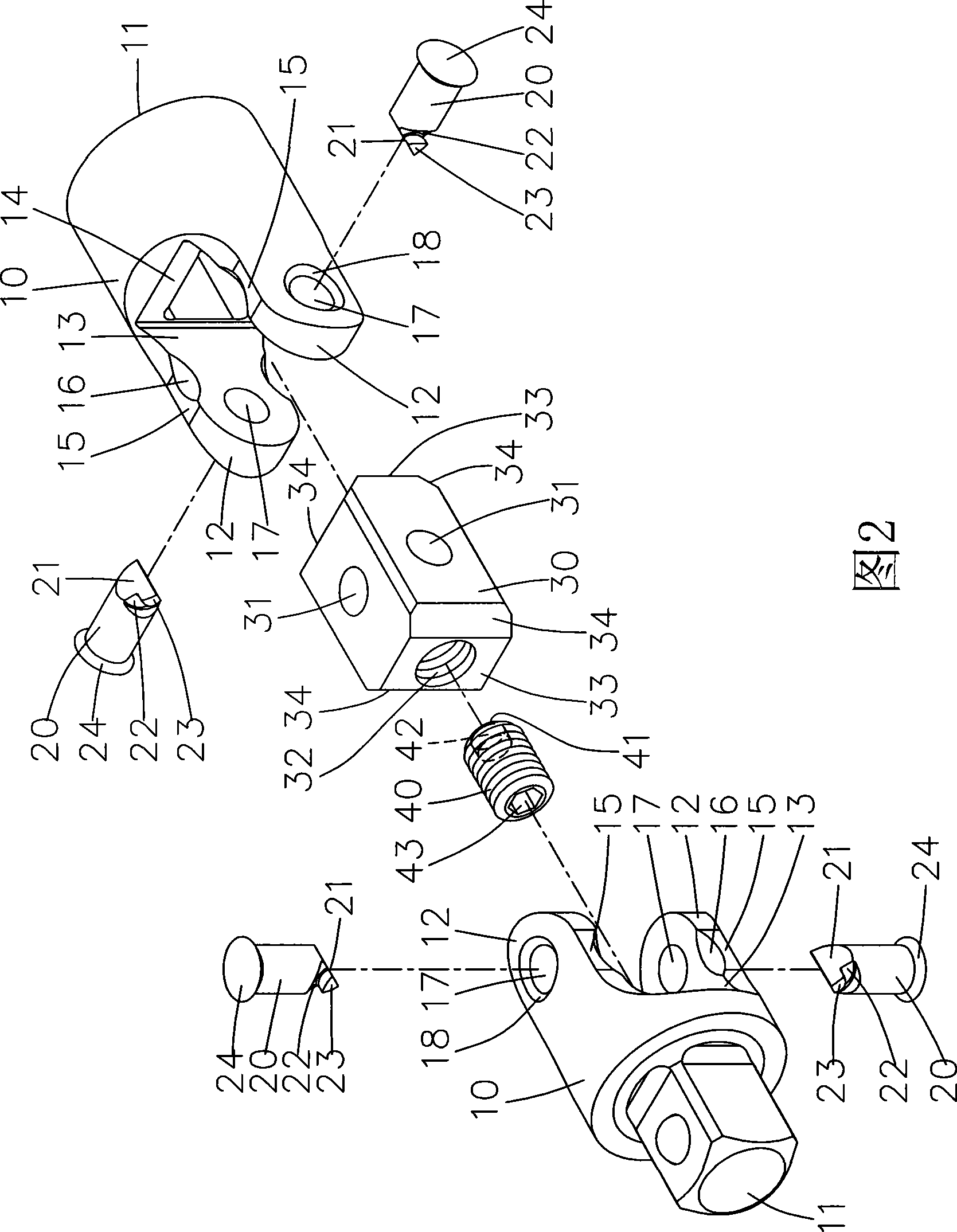

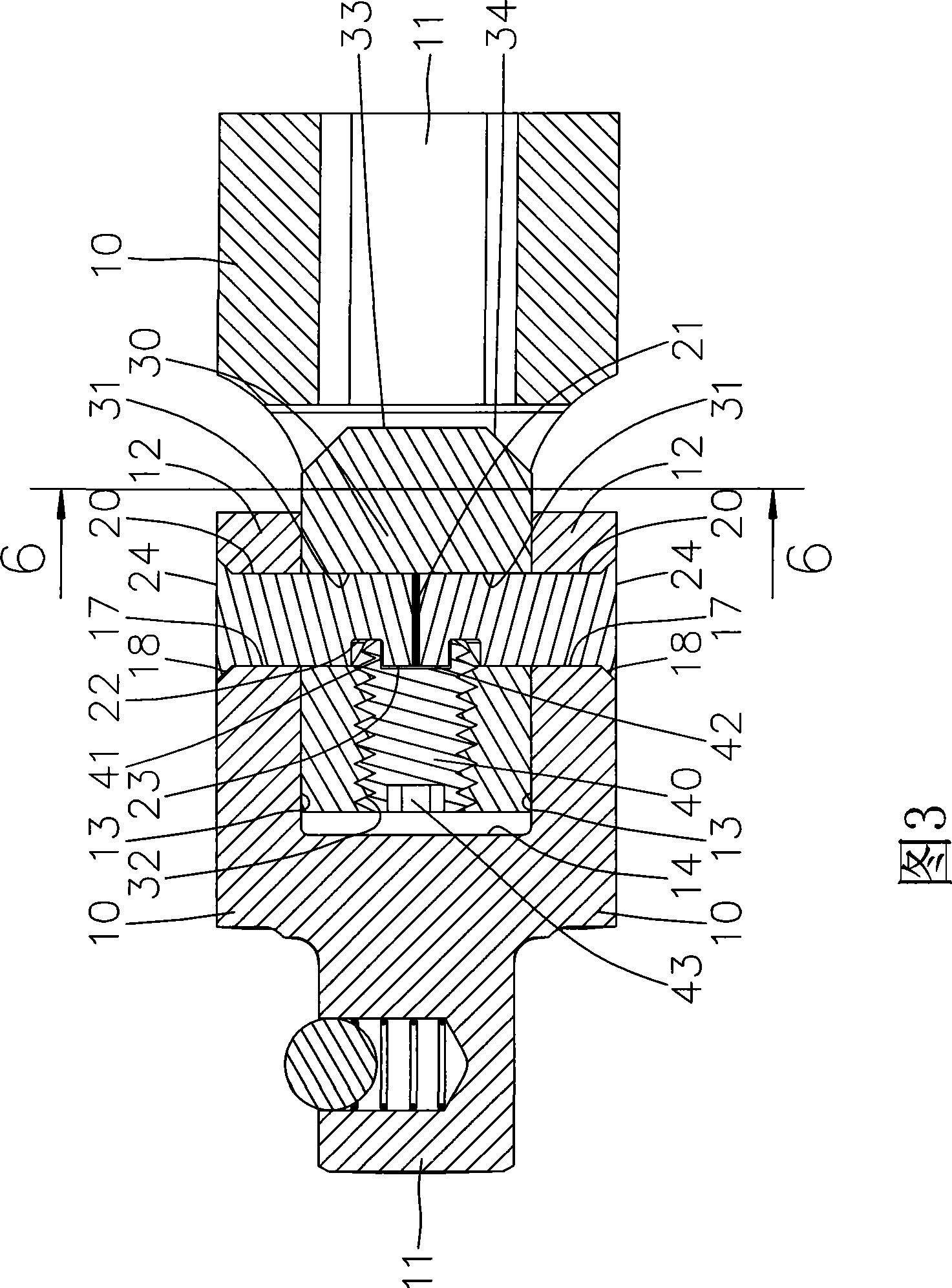

[0035] Referring to FIG. 1 and FIG. 2 , the universal joint of the present invention includes two driving parts 10 , a connecting part 30 pivotally connected between the two driving parts 10 , and a limiting part 40 disposed on the connecting part 30 . A shaft 20 is pivoted between the connecting part 30 and the two driving parts 10, and the limiting part 40 is clamped and combined with the shaft 20, so that the shaft 20 can be firmly combined in the connecting part 30, At the same time achieve the effect of detachable.

[0036] One end of the driving element 10 is provided with a coupling end 11 for connecting the driving object or the driven object. The end of the driving member 10 opposite to the connecting end 11 is provided with a pivoting end 12 . Wherein, the coupling end 11 of the driving member 10 can be configured as a sleeve shape or a square head shape, and this change can be easily accomplished by those skilled in the art.

[0037] The pivoting ends 12 of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com