Integral translational rotating compression device

A rotary compression and integrated technology, which is applied in the direction of rotary piston pumps, rotary piston machines, liquid fuel engines, etc., can solve the problems that the compression heat and friction heat of the machine cannot be quickly discharged, the cylinder is bulky, and the heat dissipation performance is poor. , to achieve the effect of improving heat dissipation and compression efficiency, simplifying processing technology, and improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

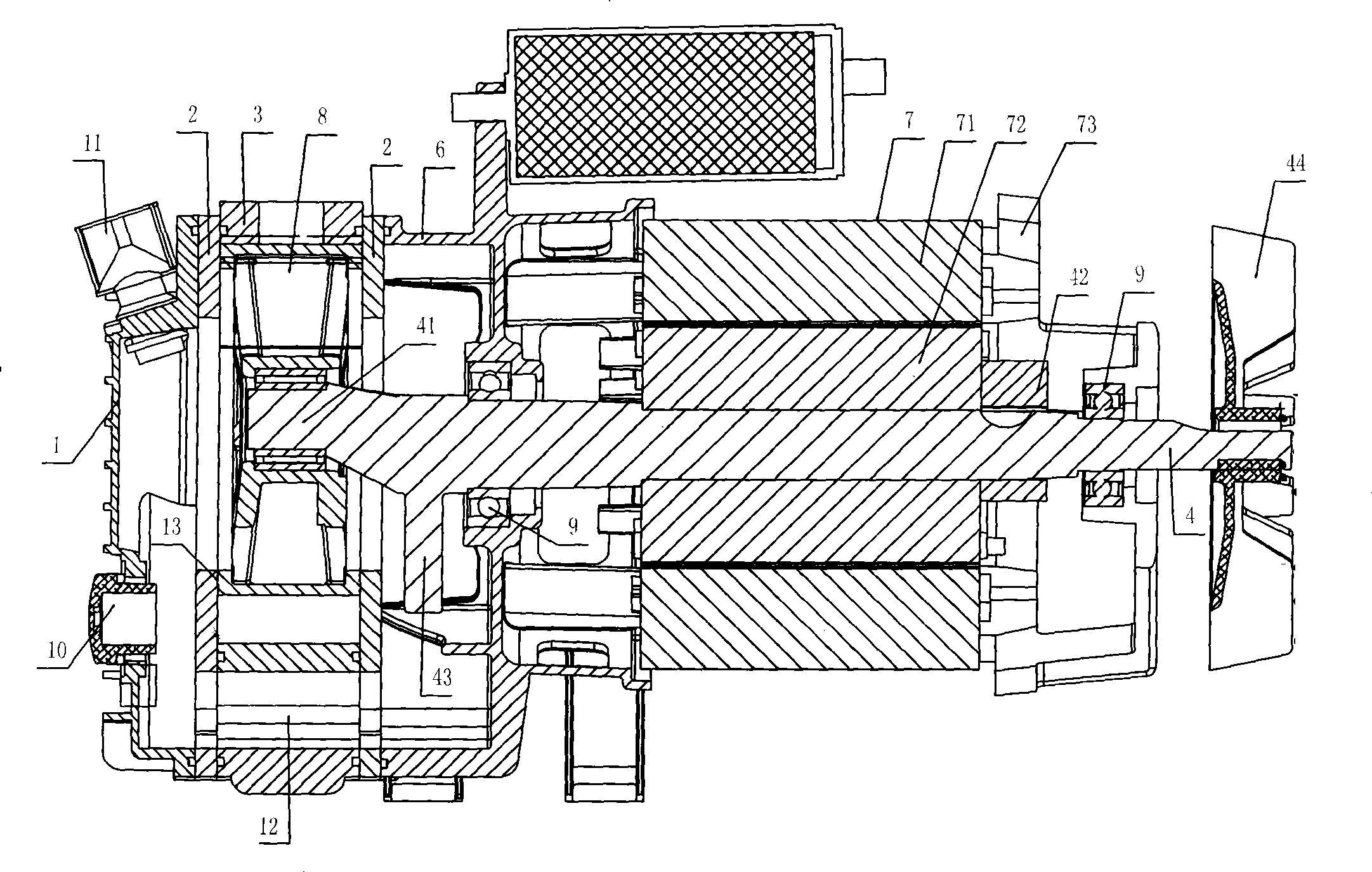

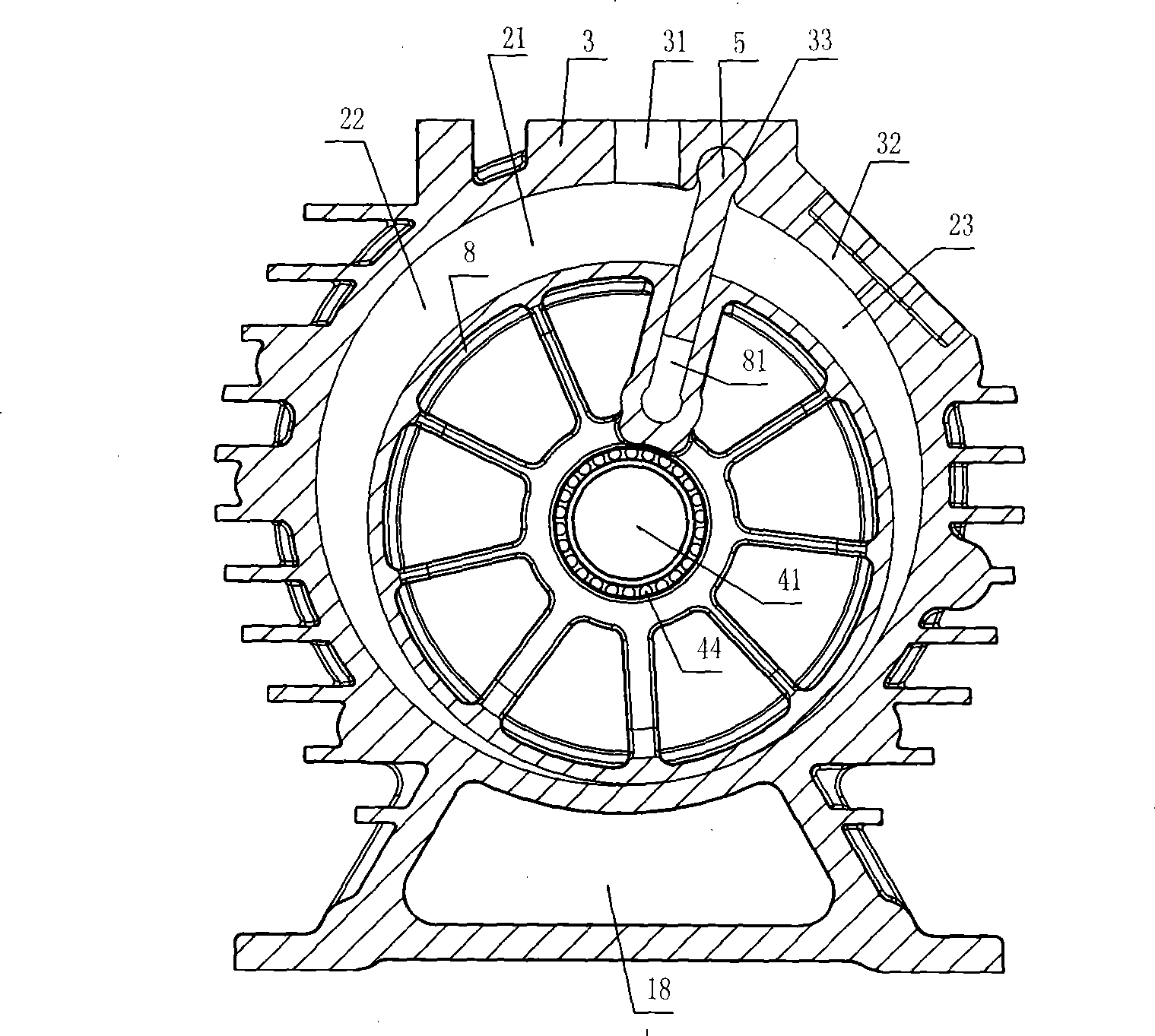

[0034] Such as figure 1 The one-piece translational rotary compression device shown includes a cylinder body 3 , a crankshaft 4 , a crankcase 6 , a motor component 7 , a slide plate 5 and a translational piston 8 . The left end of the cylinder block 3 is provided with a left end cover 1, a piston baffle 2 is arranged between the left end cover 1 and the cylinder block 3, the right end of the cylinder block 3 is connected with the crankcase 6, and the right end of the cylinder block 3 is connected with the crankcase 6. A piston baffle 2 is also provided, and a seal ring is respectively arranged between the left end cover 1 and the piston baffle 2, the cylinder block 3 and the piston baffle 2, and the piston baffle 2 and the crankcase 6. A cavity is formed between the left end cover 1 and the cylinder block 3, the bottom of the cylinder block 3 is provided with an oil groove 12, the oil groove 12 communicates with the left end cover 1 and the inner cavity of the crankcase 6, and...

Embodiment 2

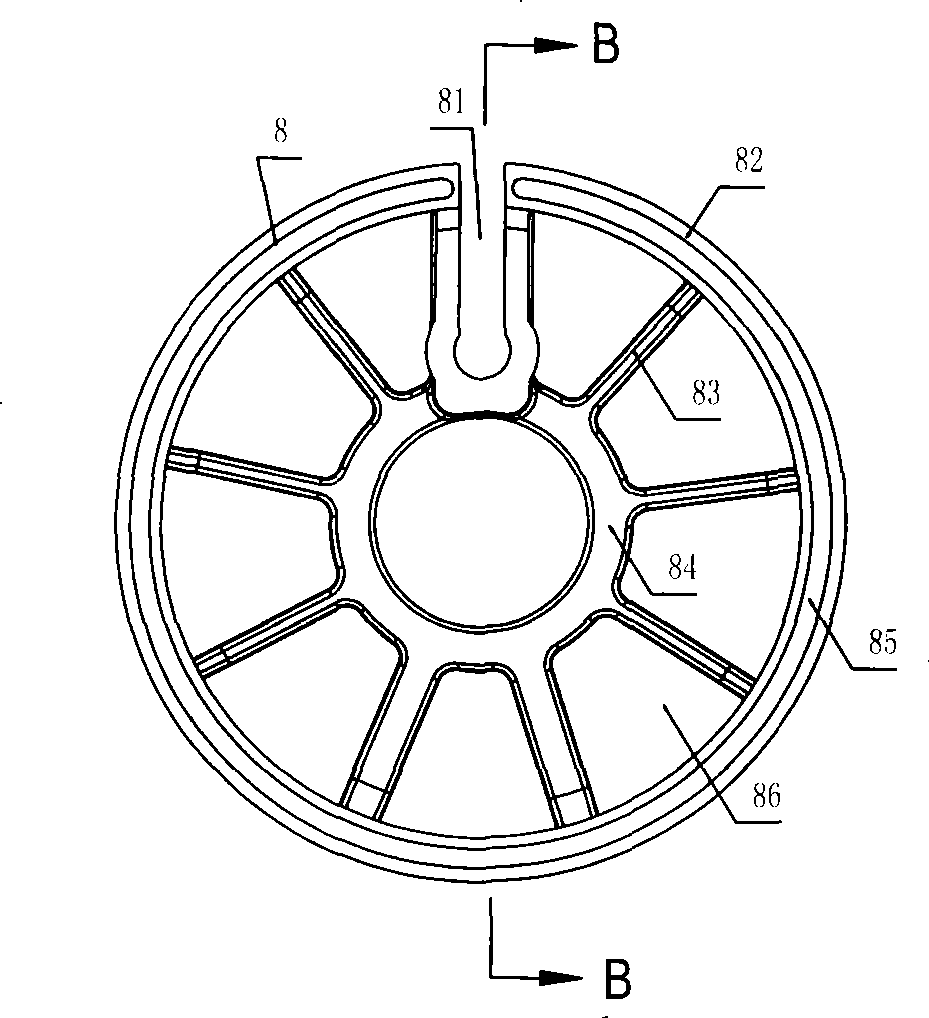

[0042] Such as Figure 5 , Image 6 As shown, the translational piston 8 includes an inner wall body 84 and an outer wall body 82 , the inner wall body 84 and the outer wall body 82 are connected by a fixed panel 87 , and a plurality of cooling through holes 88 are provided on the fixed panel 87 . Other structural features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com