Prefabricated component house and its construction method

A technology of prefabricated parts and houses, applied in construction, building materials, residential construction, etc., to achieve the effects of saving working hours and manpower, low construction costs, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

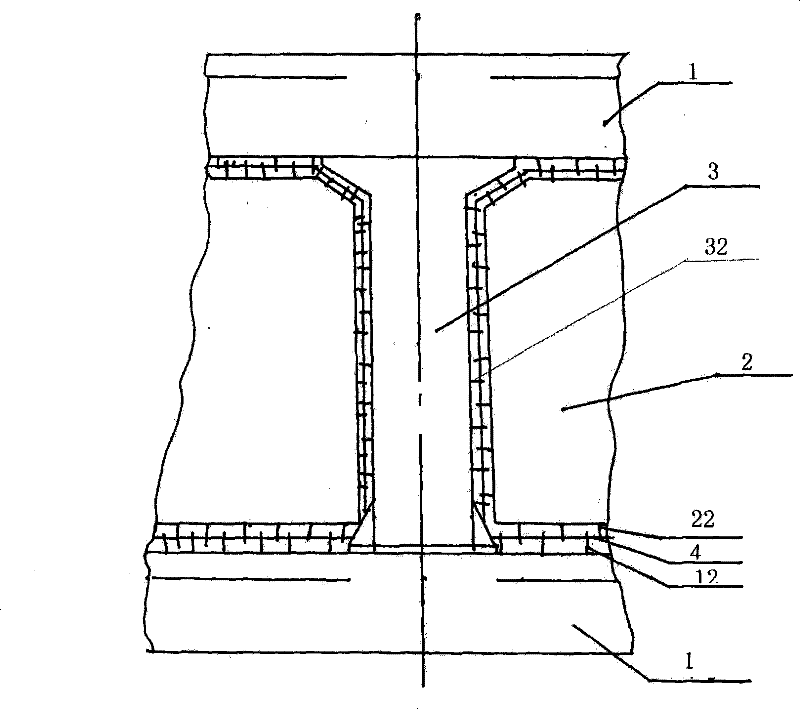

[0033] As shown in Figure 3, the prefabricated station column includes a reinforced keel and a concrete structure 31. The reinforced keel is arranged in the concrete structure 31, and a steel bar head 32 is reserved on the side and upper part of the connection between the concrete structure and the wall panel. The top of 32 can be provided with bolt structure 37, and the bottom of station column is provided with steel plate structure 33. As shown in FIG. 5 , a bolt hole 34 is provided on the steel plate 33 , and through the cooperation of the ground bolt and the bolt hole 34 , the station column can be fixed on the ground. As shown in Figure 6, the steel plate 33 at the bottom of the prefabricated station column is provided with reinforcing ribs 35, and the bottom of the steel plate 33 is drilled with some holes 36 that cooperate with the reserved steel bar heads 32. The rebar heads are welded together with the reinforcing bars and then formed in cast concrete. The side of th...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com