Penetration type inhaul cable anchorage structure

A kind of cable anchor, through-type technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of poor fatigue bearing capacity, unsatisfactory force, difficult to manufacture and install, and achieve reasonable force and easy quality control. , the clear effect of the force transmission route

Active Publication Date: 2010-11-10

ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the relatively small size of the steel truss girder members, although the traditional steel box girder cable girder anchorage structure conforms to the principles of bridge structural mechanics, it has the following defects: 1. When the lifting lug is used for anchoring, the welding seam connecting the lifting lug and the steel truss girder Direct tension, the fatigue bearing capacity is poor, and the force is not ideal; 2. When the anchor box is installed inside the rod, it is difficult to manufacture and install due to the narrow space inside the steel truss girder joint, and it is also difficult to ensure the quality of the weld

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

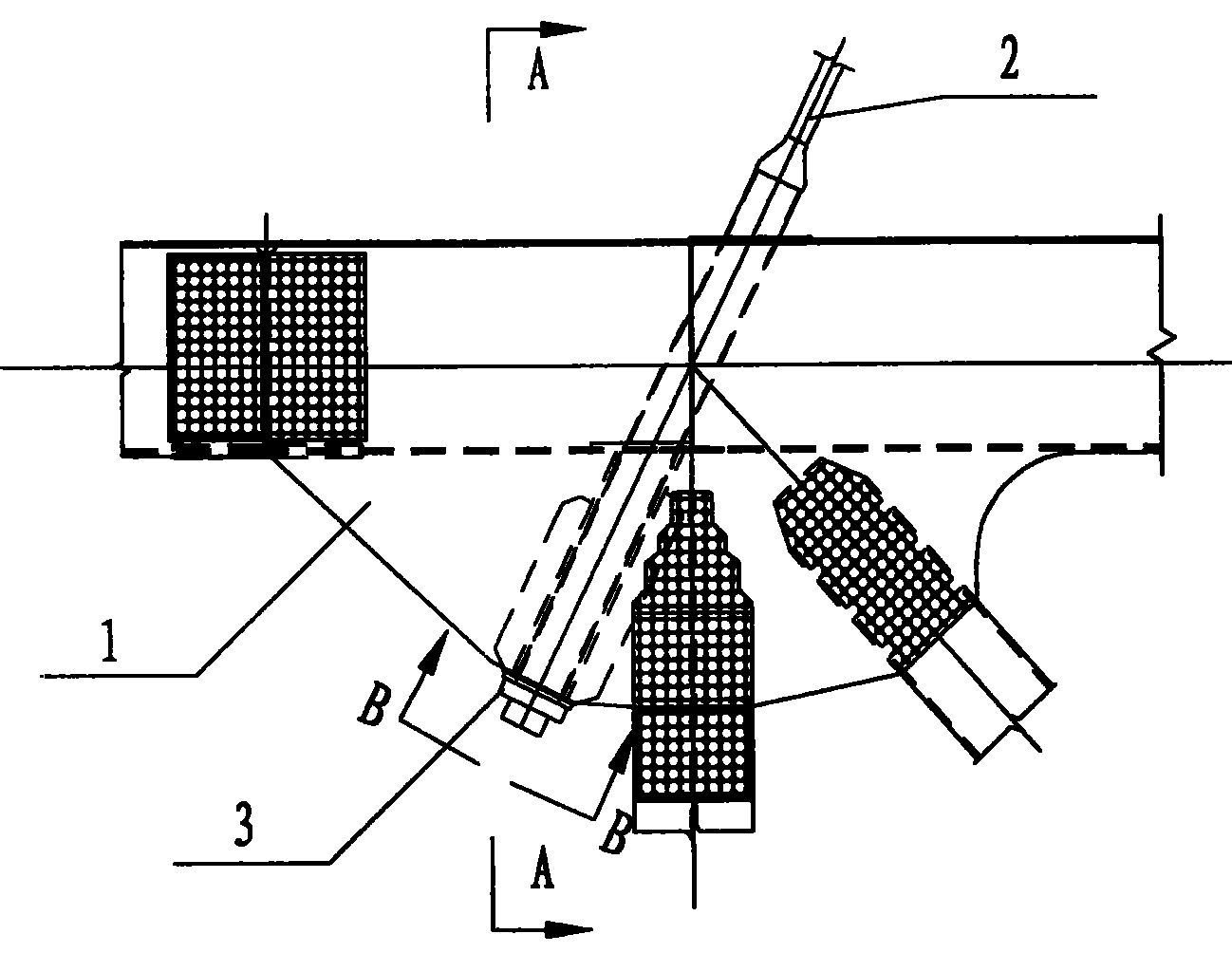

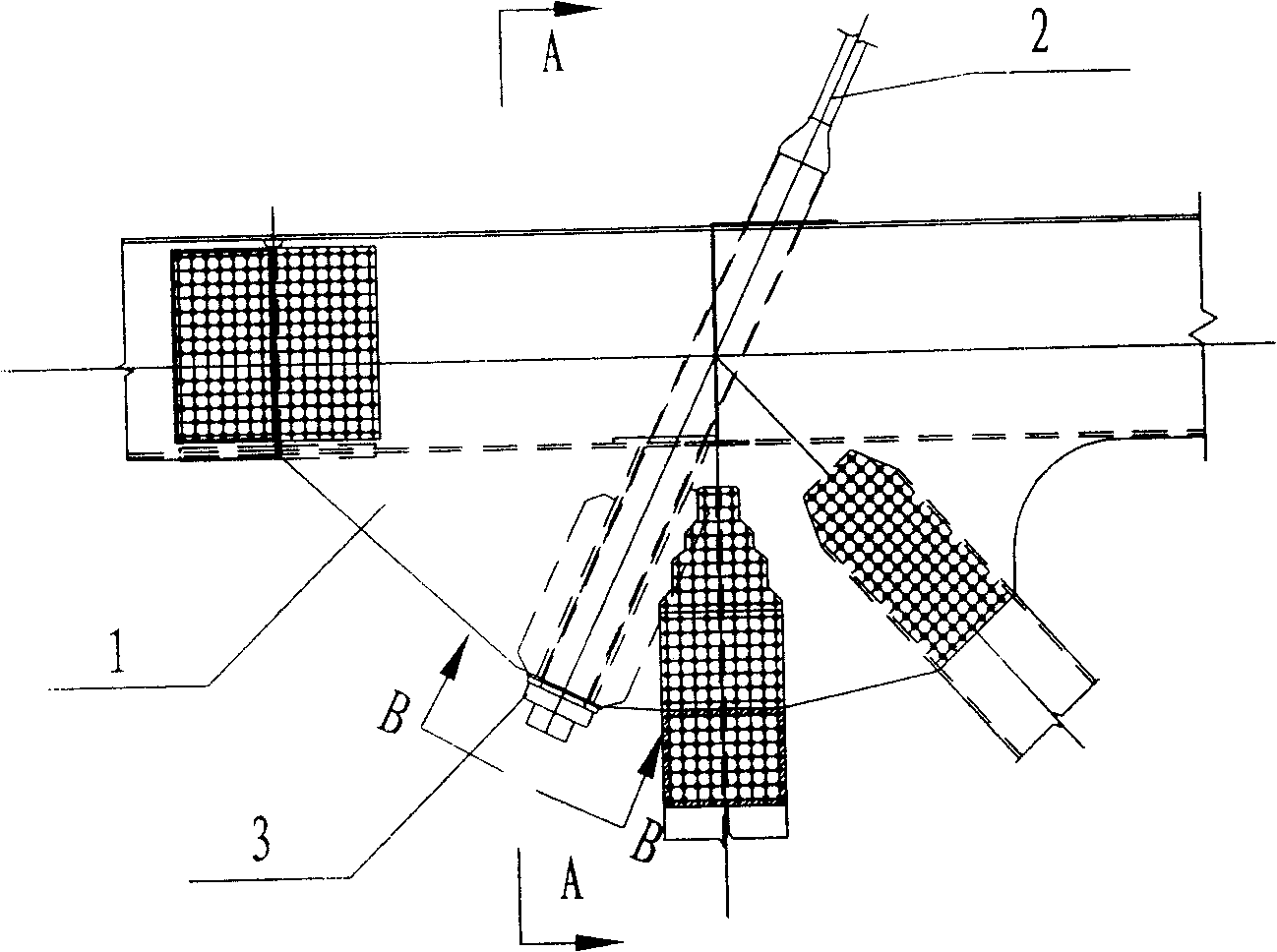

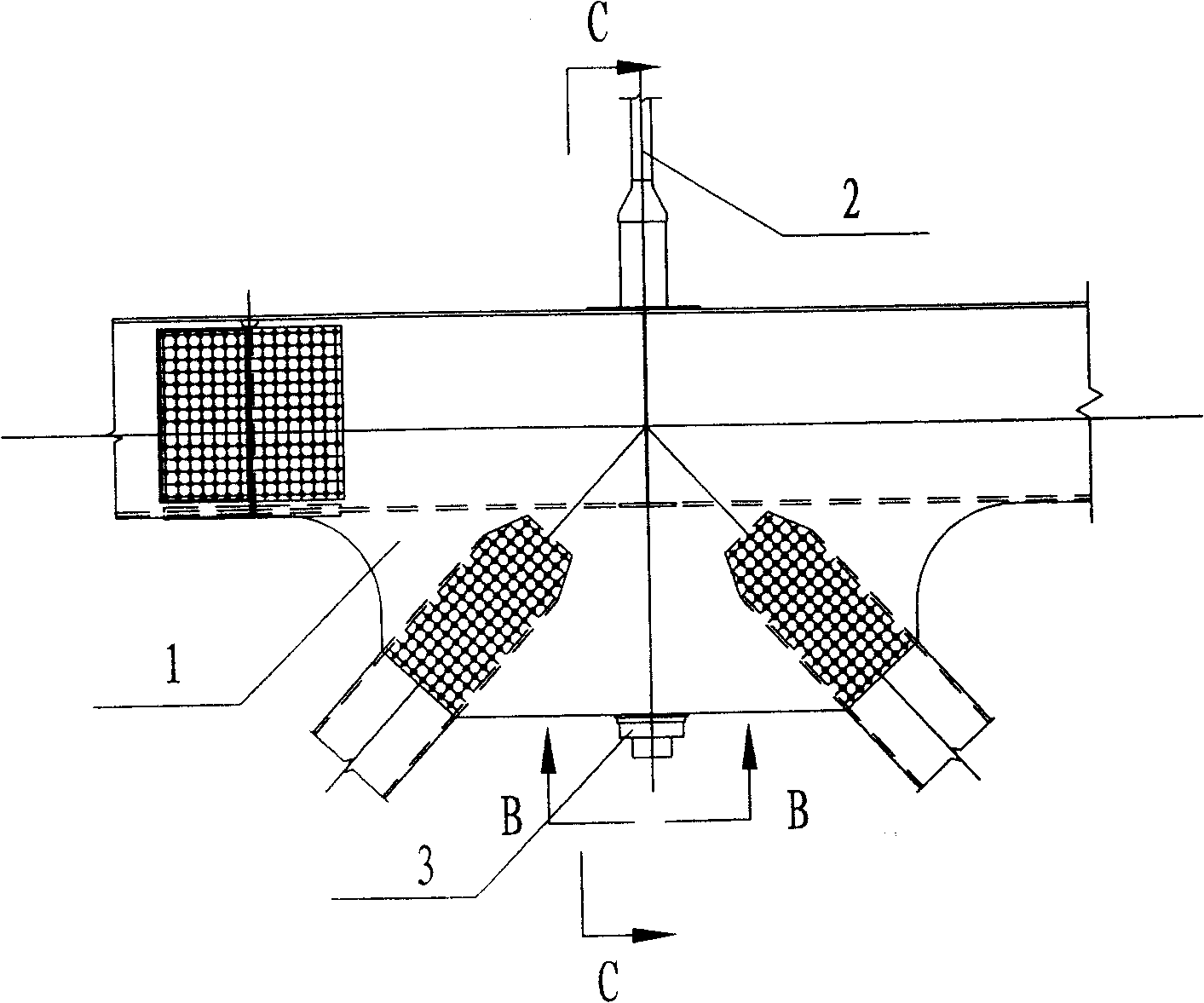

Disclosed is a traversing type cable anchoring structure, relating to an anchoring structure for cable girder gusset plates. Two anchoring plates are welded on two steel truss girder gusset plates through shearing weld joints to form a box body; and a cable anchor which is threaded through the center line of the converging point of the chord member, the diagonal rod and the montant of the steel truss girder is anchored on the anchoring plates inside the gusset plates through anchoring nuts. With the anchoring structure, the force of the cable firstly is transferred to the anchoring plates inside the gusset plates through the anchoring nuts, then is transferred to the gusset plates through the shearing weld joints of the anchoring plates and the gusset plates and is further transferred to the steel truss girder, thus avoiding the disadvantages of poor fatigue property when the pulled weld joints transfer pull loads, complexity of stress at the cable-girder anchorage zone of the steel box girder, narrow spaces inside the gussets of the steel truss girder and difficulty in quality control of the weld joints at the cable-girder anchorage zone. The cable-girder anchorage zone of the anchoring structure is simple in structure, reasonable in stress strain and has clear force transference. Meanwhile, the cable-girder anchorage zone can be manufactured in a factory and only needs to install the anchoring nuts during field construction. The traversing type cable anchoring structure is easy to manufacture and install and is convenient for quality control.

Description

Through-type cable anchoring structure Technical field The invention relates to an anchoring structure of a cable beam gusset plate. Background technique In recent decades, with the rapid development of my country’s society and economy, requirements for bridge performance have become higher and higher. As a new type of long-span cable-stayed bridge and suspension bridge stiffening beam structure, steel truss The advantages of high strength and clear force transmission routes have become more and more widely used in super-large bridges across rivers and seas. In this bridge type, the external load borne by the steel truss beam is transmitted to the main tower through the cable beam anchoring device. The cable beam anchorage area has the characteristics of large force transmission and complex force, so the design of the cable beam anchorage structure is more critical. However, due to the relatively small size of steel truss girder members, although the traditional steel box gird...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01D19/14

Inventor 徐伟高宗余刘汉顺庄勇杜萍李明华兰阳周建波

Owner ZHONGTIE MAJOR BRIDGE RECONNAISSANCE & DESIGN INST

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com