Front steering drive axle with wheel edging deceleration system

A wheel-side deceleration and drive axle technology, which is applied to the steering mechanism, steering rod, axle, etc., can solve the problems of increasing vehicle cost, wasting resources, increasing fuel consumption, etc., and achieve the effect of improving traction and off-road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

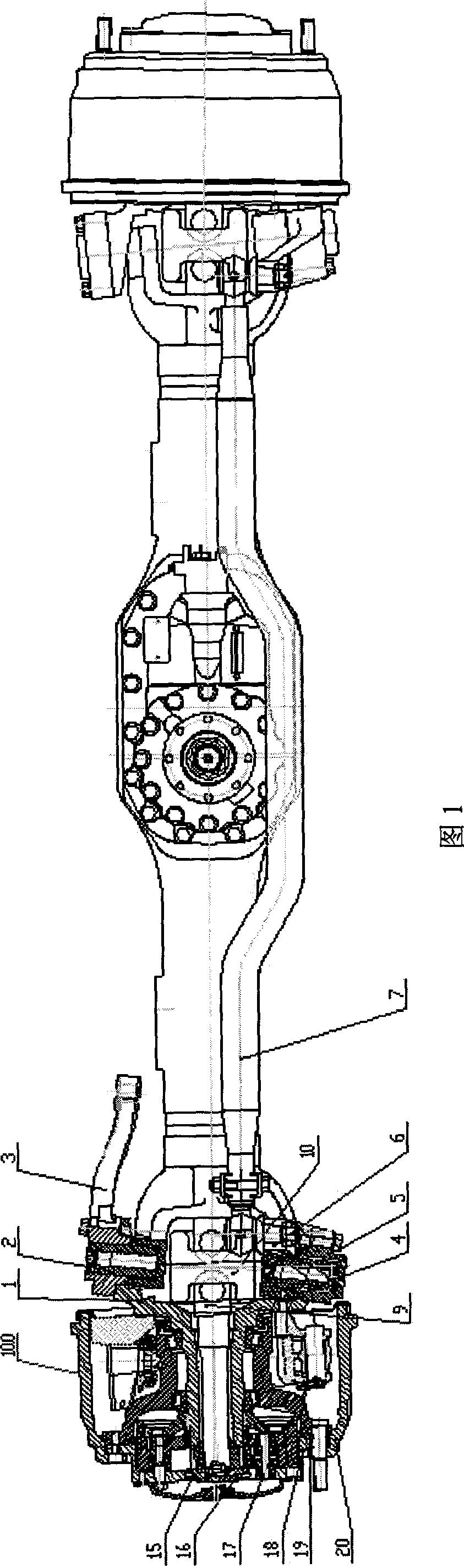

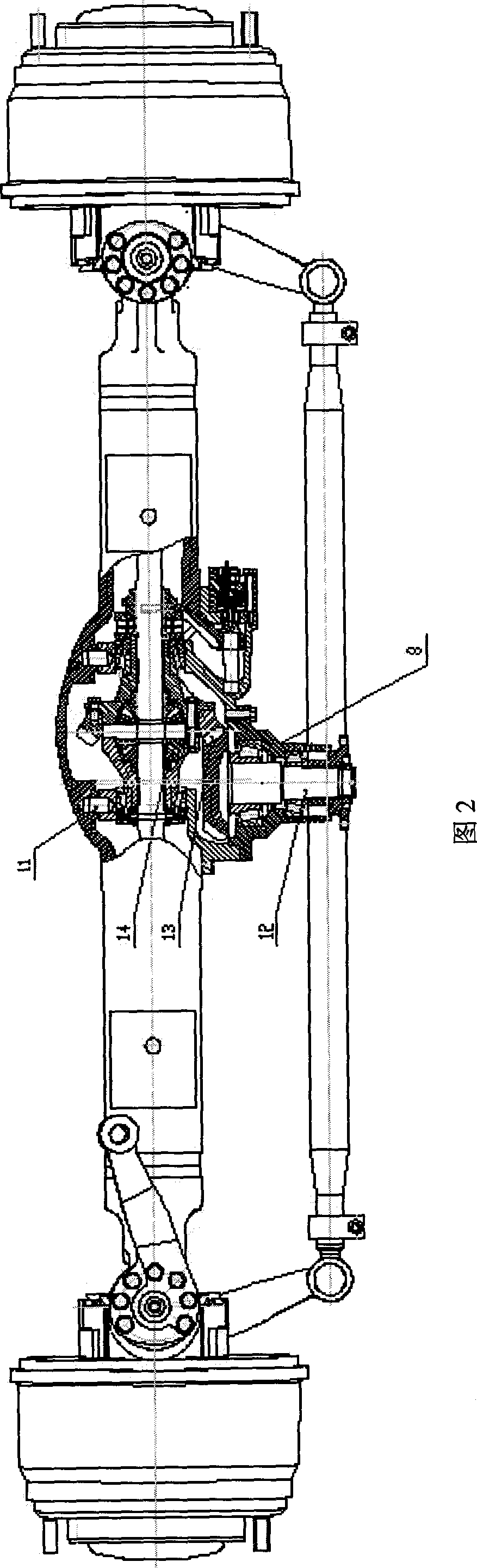

[0010] Please refer to accompanying drawing 1 of the specification and accompanying drawing 2 of the specification, a kind of wheel edge reinforced front steering double drive axle, this vehicle axle includes axle housing 100; The shell is equipped with upper kingpin 2 and lower kingpin 4 as the steering kingpin. The upper kingpin 2 is fixed on the upper end of the steering knuckle 1 through a bush, the upper kingpin 2 is connected with the steering knuckle arm 3, and the lower kingpin 4 is passed through a rolling bearing. 5. The tie rod arm 6 fixed on the lower end of the steering knuckle 1 and connected with the tie rod assembly 7 forms the steering mechanism of the wheel. The final reducer assembly 8 is assembled to the axle housing assembly through the positioning pin 11; The left and right half shafts 9 of the vehicle axle are all divided into inner and outer two ends, and are connected with a constant velocity universal joint 10 whose center is located on the center line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com