Connecting rod bushing press-loading device and method

A technology of connecting rod bushing and press-fitting device, which is applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unusable and out-of-tolerance connecting rod assemblies, and achieve uniform and ideal press-in, reducing Moment, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

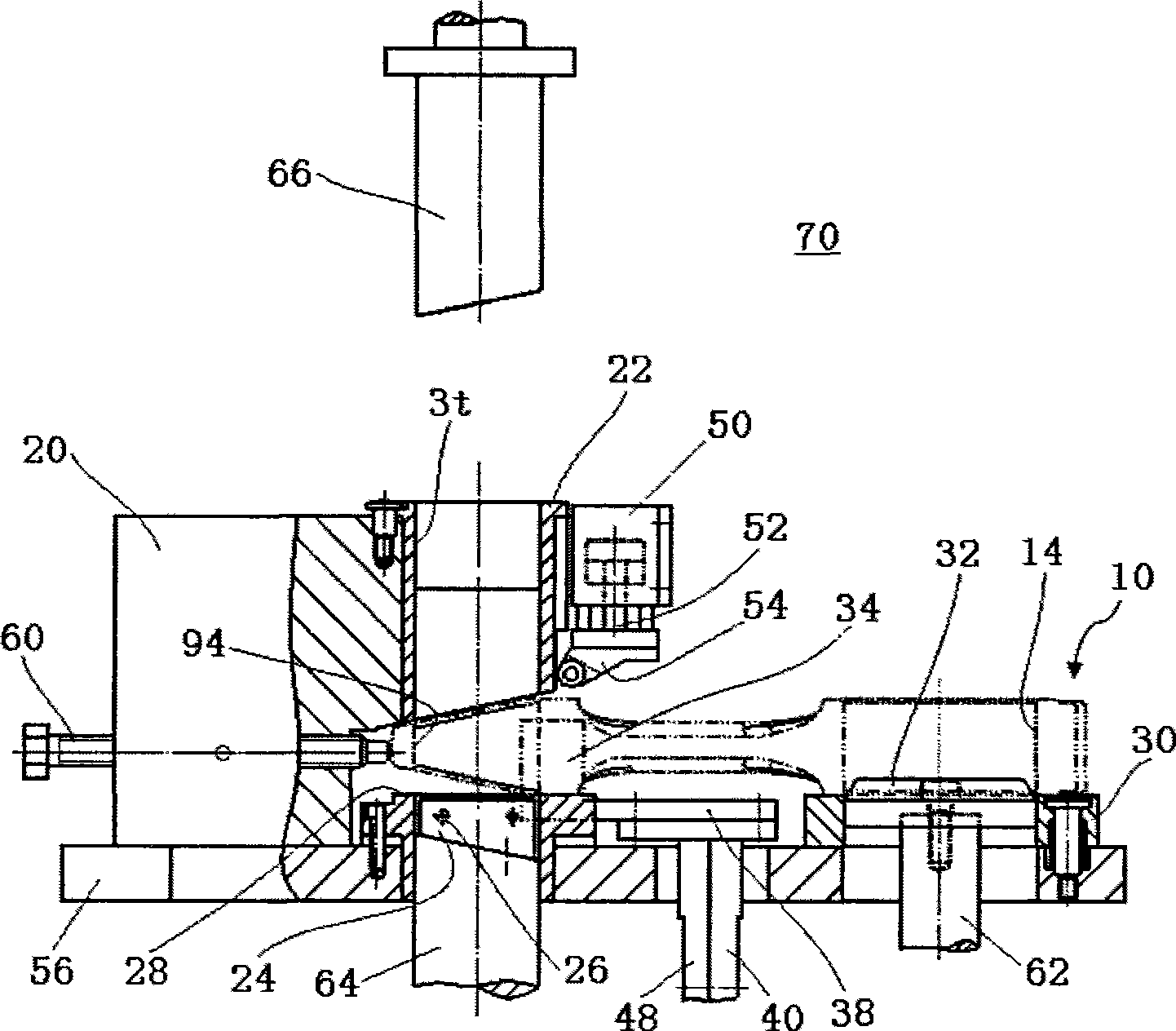

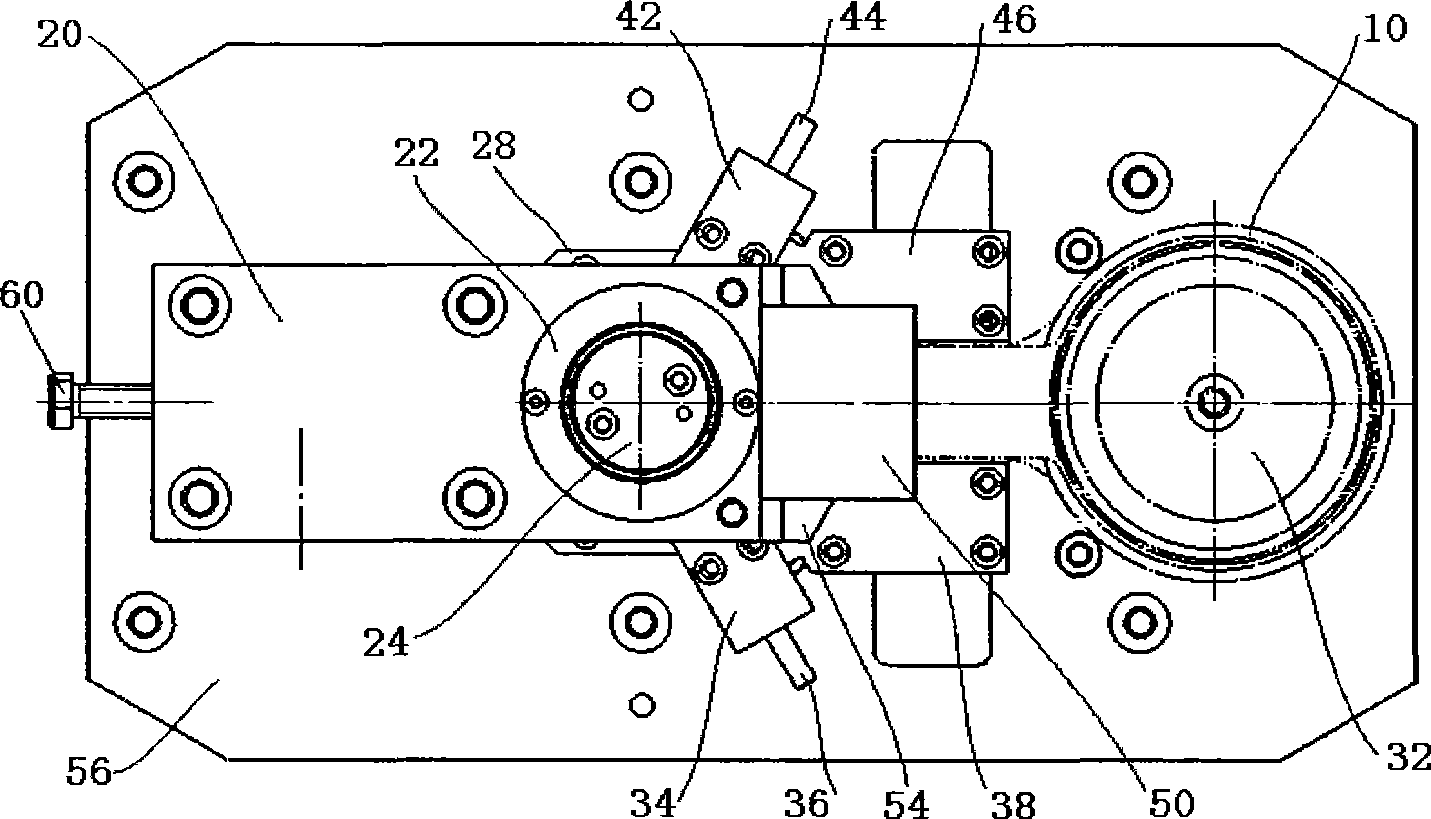

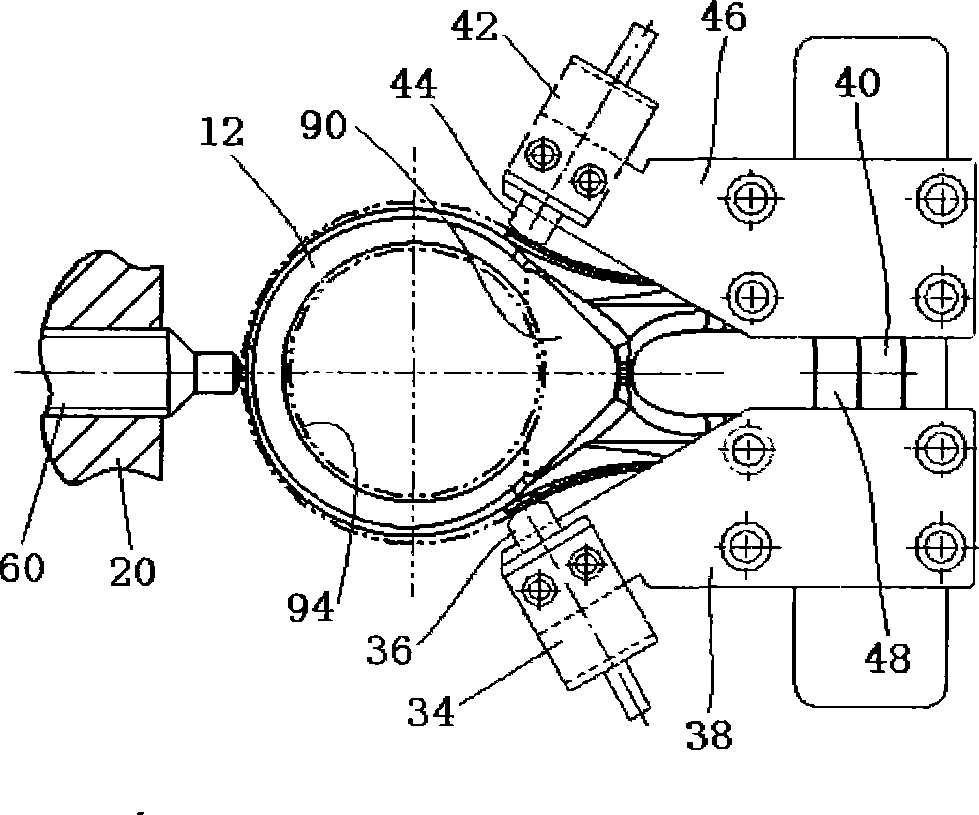

[0043] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0044] Figure 6A It is a sectional view of the wedge-shaped bushing 16. The bushing 16 has an upper slope 80 and a lower slope 82, an inner lining surface 84, an outer lining surface 88, and a press-fit positioning process hole 86 on the inner wall of the bushing. Figure 6B It is a sectional view of the small end 12 of the connecting rod 10. The upper and lower end surfaces of the small end 12 of the connecting rod are composed of inclined surfaces 96, 98 and narrow planes 90, 92. The outer edge of the pin hole 94 of the small end 12 is processed with chamfers (not Shows). The bush pressing device and method provided by the present invention are Figure 6A The wedge bushing 16 shown is press-fit evenly into the Figure 6B In the pin hole 94 of the small end 12 of the connecting rod 10 shown, Figure 6C It is a cross-sectional view of the bushing 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com