Comb type polar post for accumulator through-hole welding

A technology of through-wall welding and battery, applied in battery pack parts, circuits, electrical components, etc., can solve the problems affecting the quality and service life of batteries, busbar fracture, insufficient firmness, etc., to improve high-current discharge capacity, The effect of preventing false welding and reasonable overall structure design

Inactive Publication Date: 2009-02-04

WOLONG ELECTRIC GRP CO LTD +1

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, for the large-capacity batteries of lead-acid batteries used for starting automobiles, the middle pole used for penetrating the wall is generally a small 7-shaped structure composed of conductive electrodes and short steps. False welding is easy to occur when welding the electrode group, and the firmness is not enough. At the same time, when the battery is discharged with a large current during use, there are many cases of breakage between the bus bar and the pole, which will easily lead to the scrapping of the battery.

Seriously affect the quality and service life of the battery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

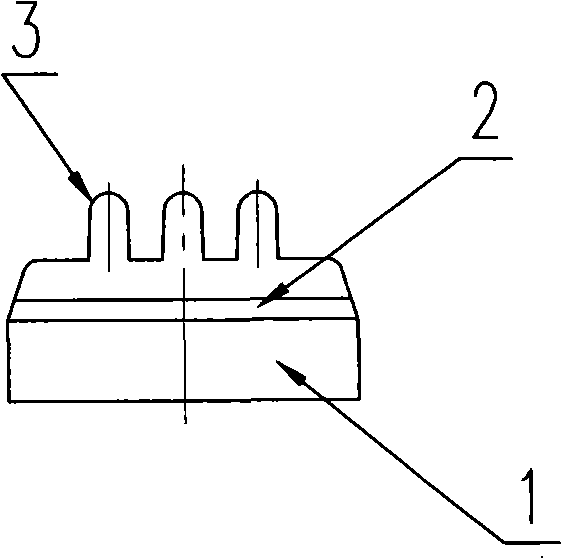

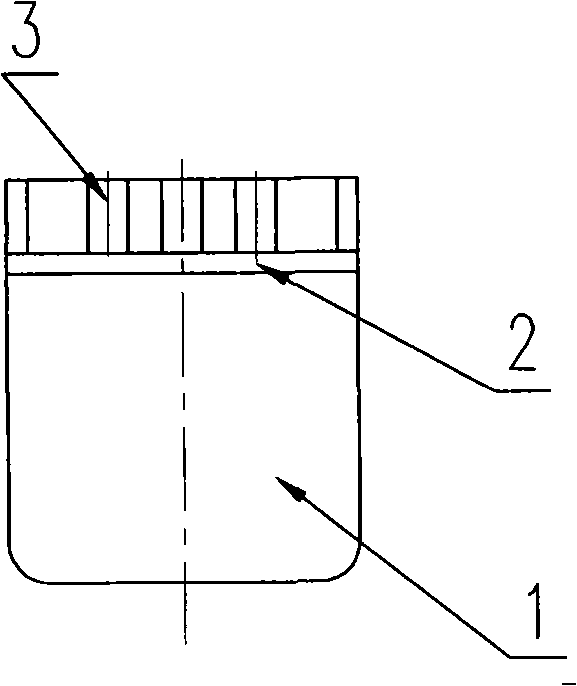

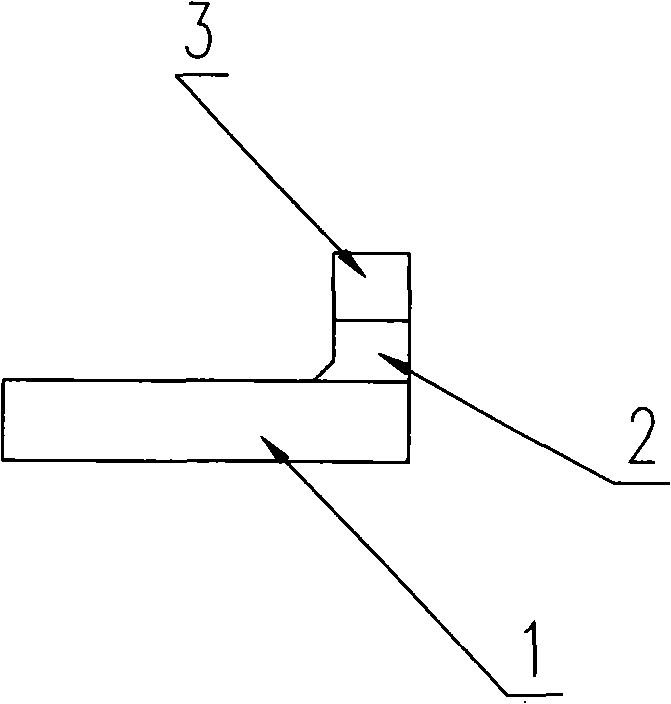

[0011] The present invention is mainly composed of a pole conducting electrode 1, a short step 2 placed at one end of the pole conducting electrode 1, and comb-shaped small teeth 3 placed on the short step 2. The number of comb-shaped small teeth 3 is 3 to 6.

[0012] When in use, as long as the present invention is placed on the welding mold 5, the comb-shaped small teeth 3 at the bottom and the plate ears 4 are fused together to form a busbar.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Disclose is a comb-shaped terminal post used in a through-wall welding of storage battery, belonging to the field of lead-acid storage battery manufacturing technology, which essentially comprises a terminal post conductive electrode (1), a short step (2) which is disposed on one end of the terminal post conductive electrode (1) and small comb-shaped teeth (3) which are arranged on the short step (2), and the like, wherein the number of teeth of the small comb-shaped teeth (3) is 3 to 6; and the using process is that as long as the comb-shaped terminal post is placed on the welding mold (5), the small comb-shaped teeth (3) which are disposed at the bottom thereof are melted together with the plate lugs (4) of the polar plate so as to form a cylinder manifold. The overall structure is rational in design, so that the comb-shaped terminal post can be firmly combined together with the cylinder manifold by making use of the small comb teeth part of the terminal post without affecting the designed size of the battery, so as to improve the performance of the storage battery; and false soldering and inveracious soldering of the terminal post can be effectively prevented, so as to improve the high current discharge capacity of the storage battery and extend the service life of the battery.

Description

technical field [0001] The invention relates to a comb-shaped pole post for battery through-wall welding, belonging to the technical field of lead-acid battery manufacture. Background technique [0002] At present, for the large-capacity batteries of lead-acid batteries used for starting automobiles, the middle pole used for penetrating the wall is generally a small 7-shaped structure composed of conductive electrodes and short steps. It is easy to produce false welding when welding the electrode group, and the firmness is not enough. At the same time, when the battery is discharged with a large current during use, there are many cases of breakage between the bus bar and the pole, which will easily lead to the scrapping of the battery. Seriously affected the quality and service life of the battery. Contents of the invention [0003] The object of the present invention is to provide a comb-shaped post for battery through-wall welding with reasonable design, which can effec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M2/30H01M2/26H01M50/507H01M50/552

CPCY02E60/10

Inventor 裘小平唐伟成

Owner WOLONG ELECTRIC GRP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com