Crankshaft milling crutch indexing fixture

A fixture and crankshaft technology, which is applied in the field of crankshaft grinding and indexing fixtures, can solve the problems of difficult to ensure accuracy requirements, labor and time-consuming, etc., and achieve the effects of high production efficiency, wide indexing range, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

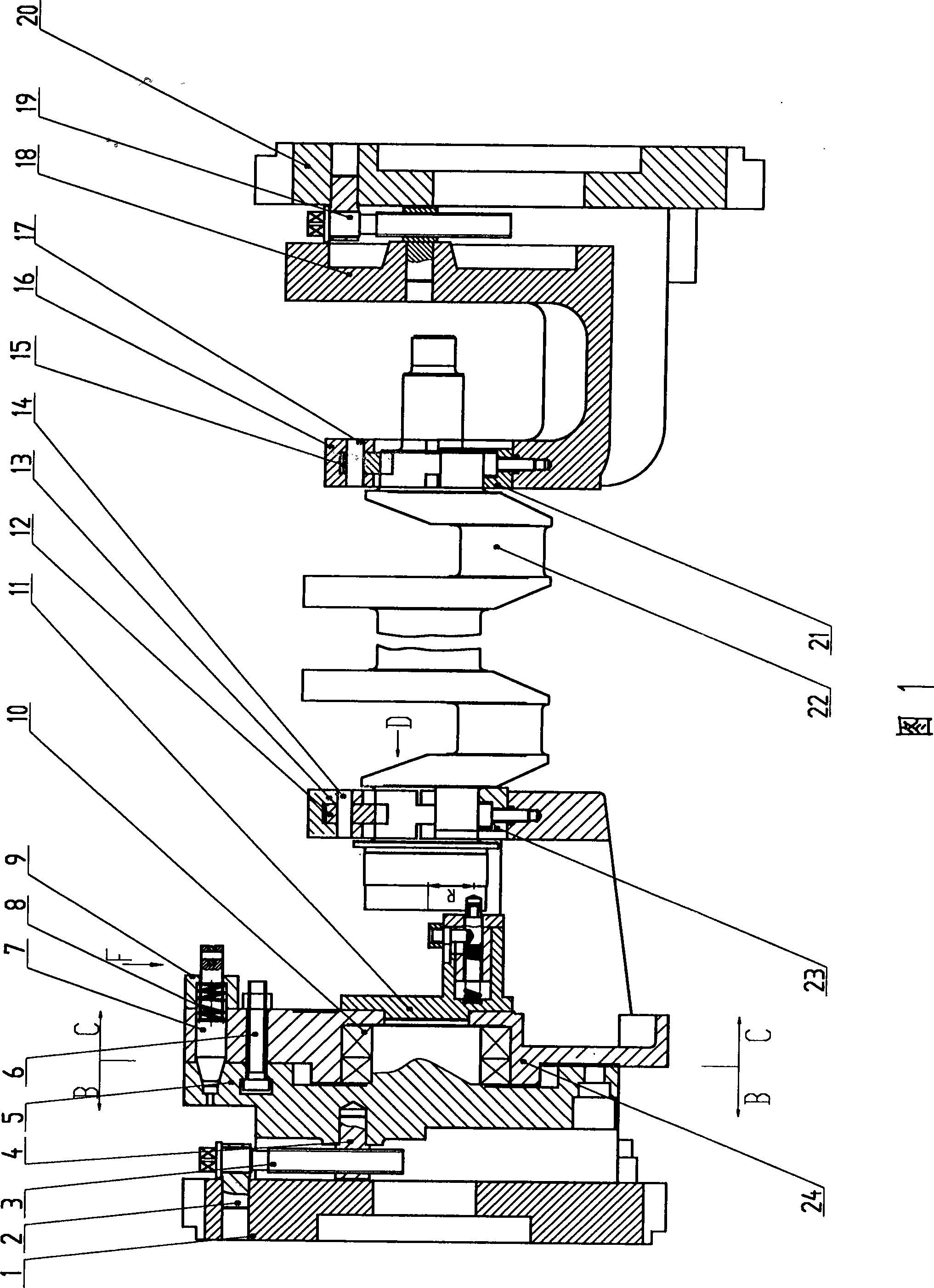

[0018] From figure 1 It can be seen that the present invention is an indexing fixture for crankshaft grinding, which includes left and right eccentricity adjustment mechanisms, left and right clamping mechanisms, indexing mechanisms, positioning mechanisms, and the like. The left and right eccentricity adjustment mechanisms are located at the left and right ends of the fixture. Wherein, the left eccentricity adjustment mechanism mainly includes connecting plate 1, a lead screw 3 installed on the connecting plate 1 through a fixed sleeve 2, a nut 4 matched with the leading screw 3 installed on the fixture base 5, and one end of the connecting plate 1 is installed on the machine tool spindle, The other end is connected with the clamp base 5 through a rectangular track, and the rotating lead screw 3 drives the left clamp body and the clamp base 5 to move relative to the connecting plate 1 through the nut 4 to adjust the left eccentricity of the crankshaft. The right eccentricity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com