Method and device for application of self-adhesive foil

A film and self-adhesive technology, applied in adhesives, decorative art, thin material processing, etc., can solve time-consuming, troublesome and other problems, and achieve good functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

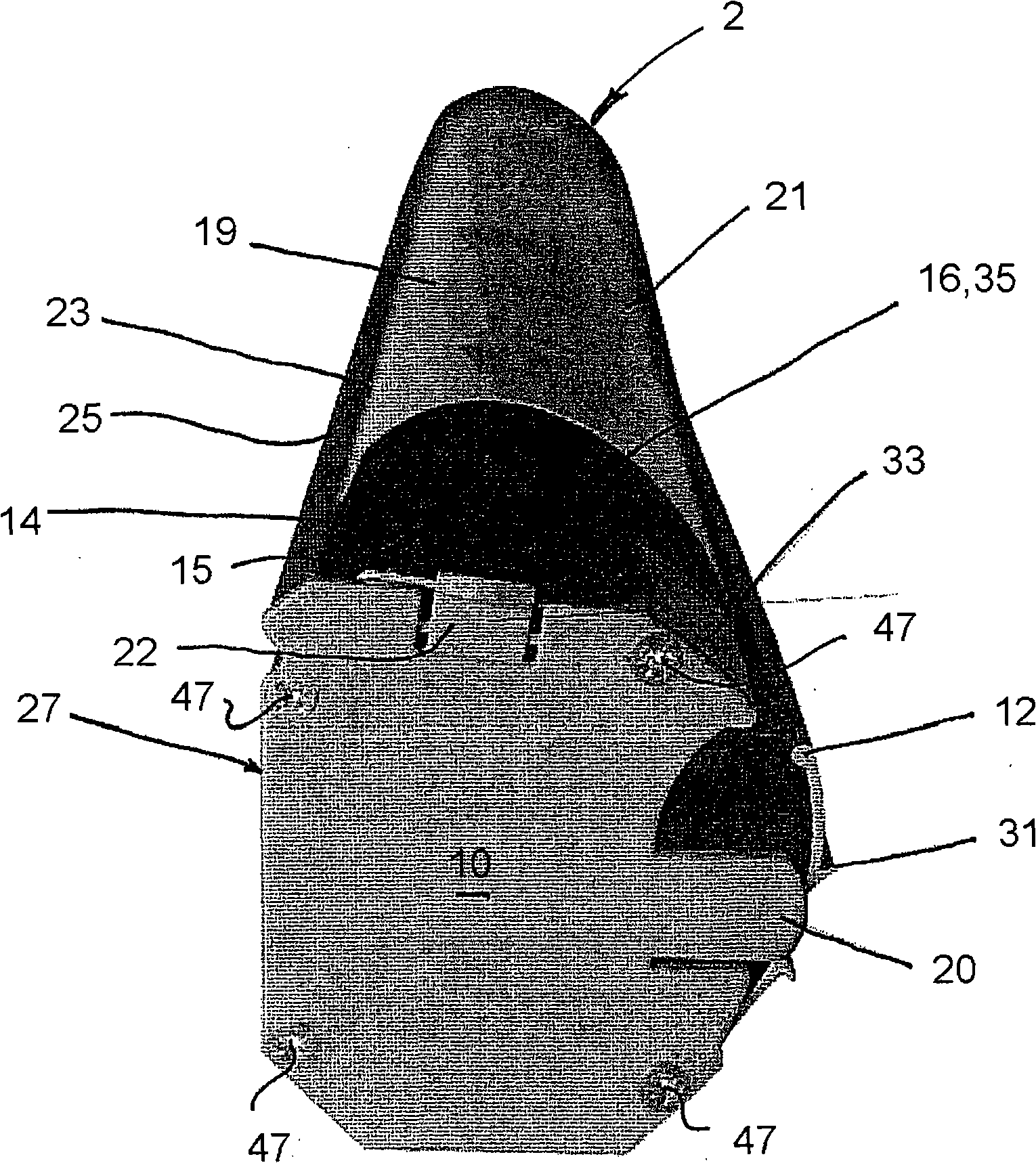

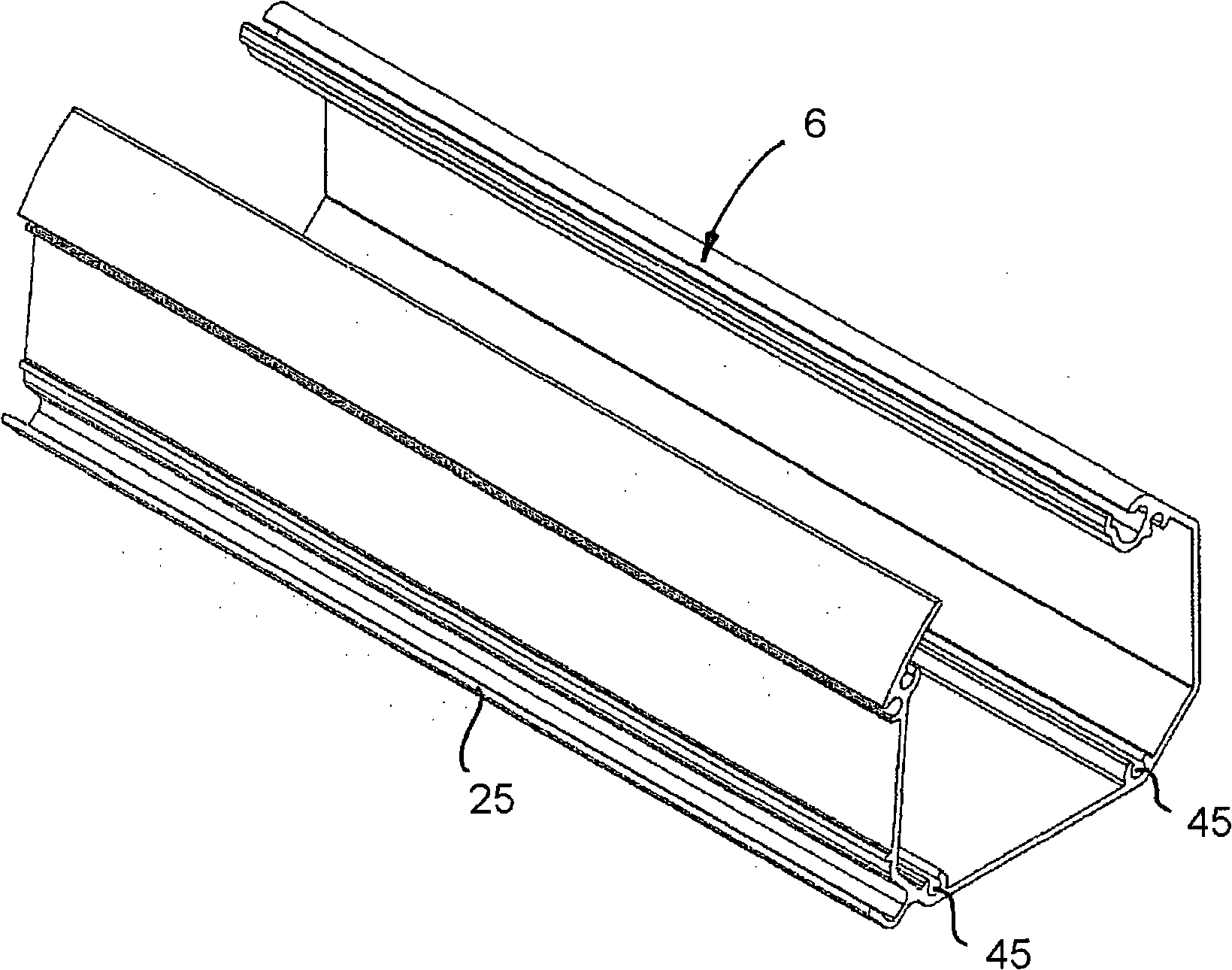

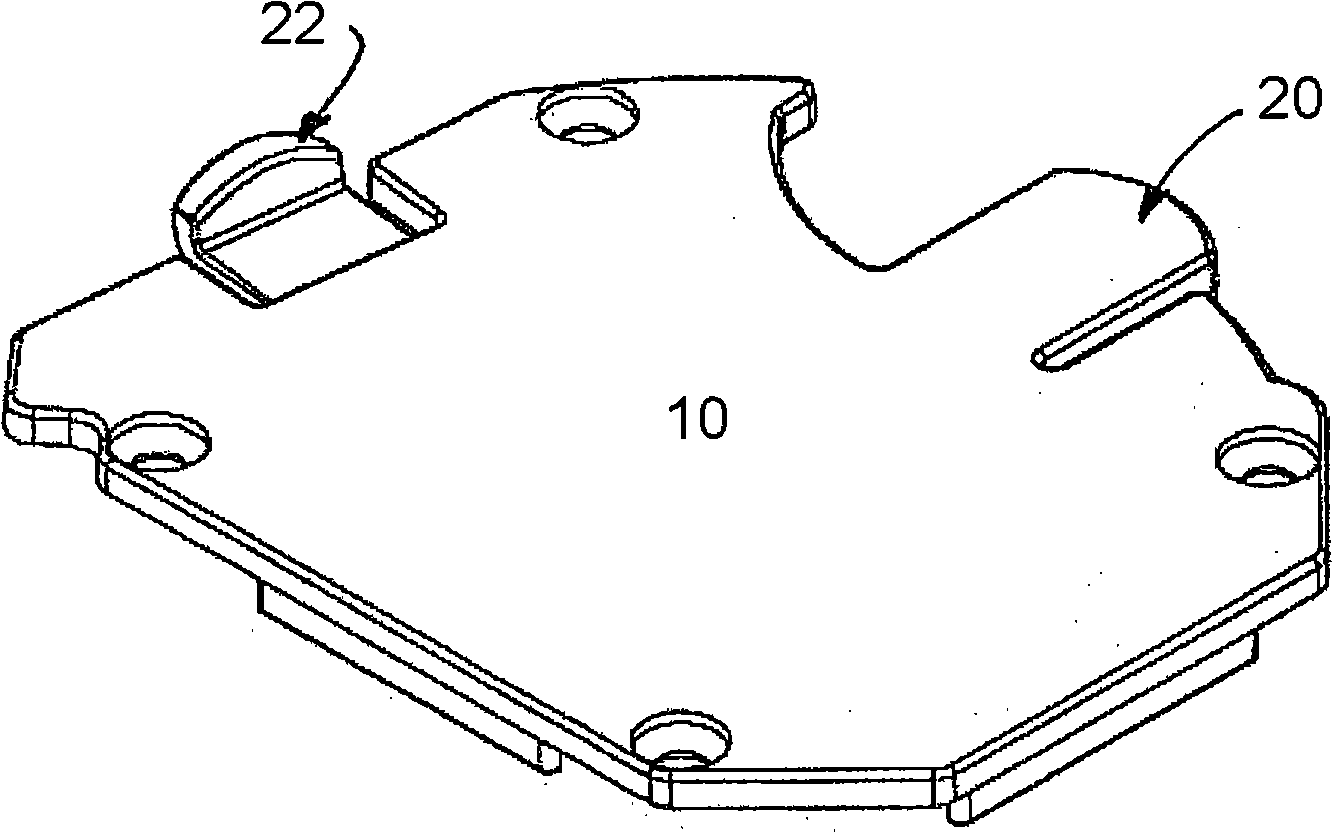

[0043] figure 1 -9 and 22-24 show a preferred embodiment of the film application device 2 according to the present invention, wherein the elongated device housing 4 comprises figure 2 Longitudinal aluminum profile 6, in use Figure 3-6 The left and right end covers 8, 10, Figure 7 The elongated cover, the combined extrusion face and fixed plate member 14 of FIG. 8 , and the associated extrusion body 16 of FIG. 9 .

[0044] exist figure 1 The film applicator 2 shown in is substantially ready for use, since it is ready to insert a rolled film 19 with a liner 21 (backing paper), the free upper edge 37 of which is secured to a firm holding edge 25 and fixed plate member 14, which is spring biased outwards and can be secured by locking teeth 22 of each end cap 8, 10 when in the open, inwardly moved position .

[0045] exist figure 1 The left side shows the flat top side 27 in use, which serves as an aiming device for correcting the positioning of the film applicator 2 in a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com