Work management apparatus and work management method

A technology of operation management and operation, applied in data processing applications, comprehensive factory control, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

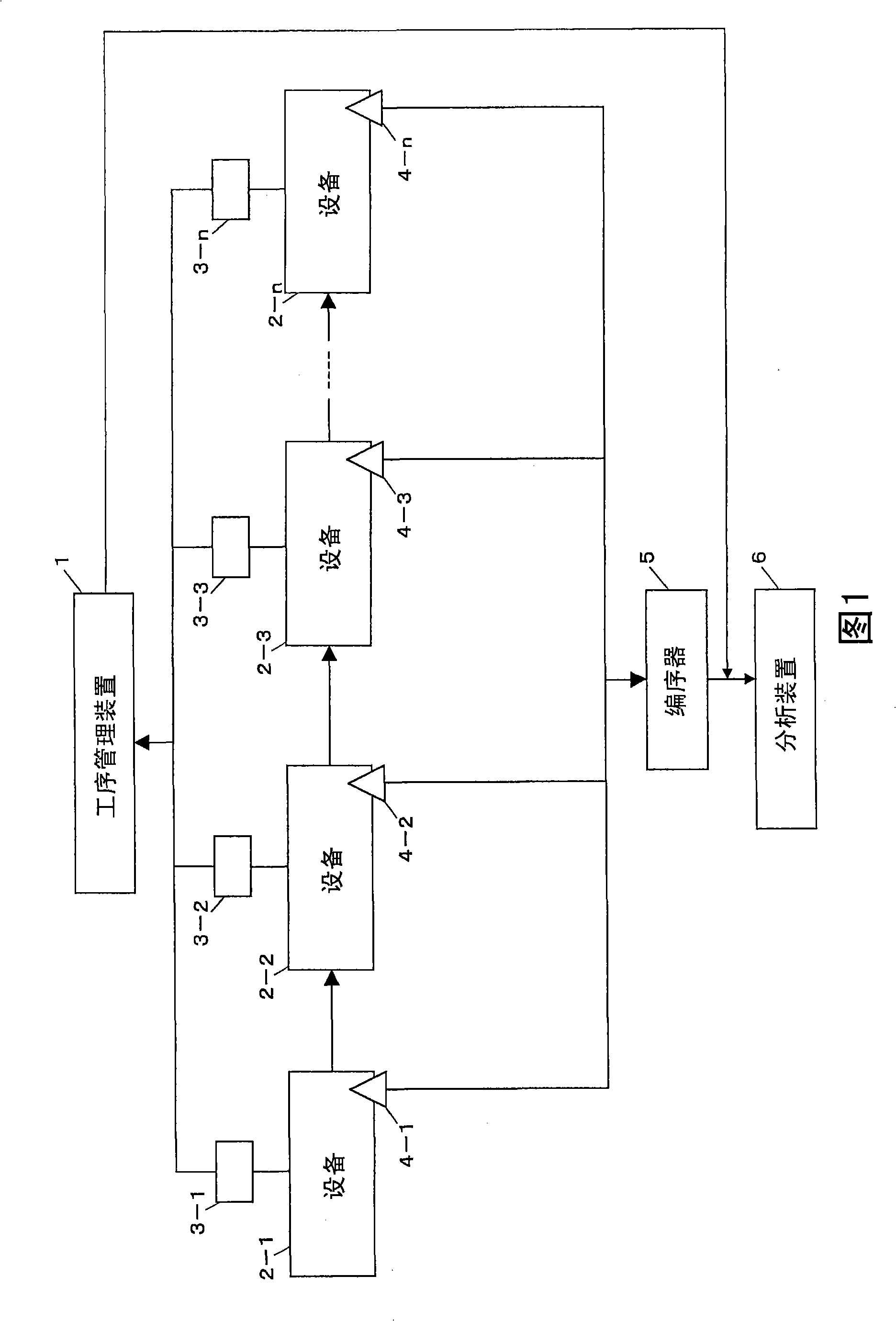

[0054] FIG. 1 is a view showing an example of the structure of a job management apparatus of the present invention. The job management device of this embodiment is a job management device used on a production line where one or more target objects are processed in a plurality of equipment (equipment 2-1 to 2-n) on the production line. The job management device analyzes the operation status of each device and the job progress of the target object in each device, and then outputs the analysis result.

[0055] The job management device of this embodiment includes a process management device 1, barcode readers 3-1 to 3-n, sensors 4-1 to 4-n, a sequencer 5, and an analysis device 6.

[0056] The process management device 1 obtains the detection results of the input and output of the target objects arriving and leaving each device in each device, and the detection result is obtained by the barcode reader connected to the device of each process, and is obtained based on the detection resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com