Reducing prestress structure system before prestressed reinforcement withdrawing tension

A prestressed steel bar and untensioning technology, which is applied in the direction of building construction, construction, and building material processing, can solve problems such as waste of cost, waste of resources, and reduction of the design value of the tensile force of prestressed steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

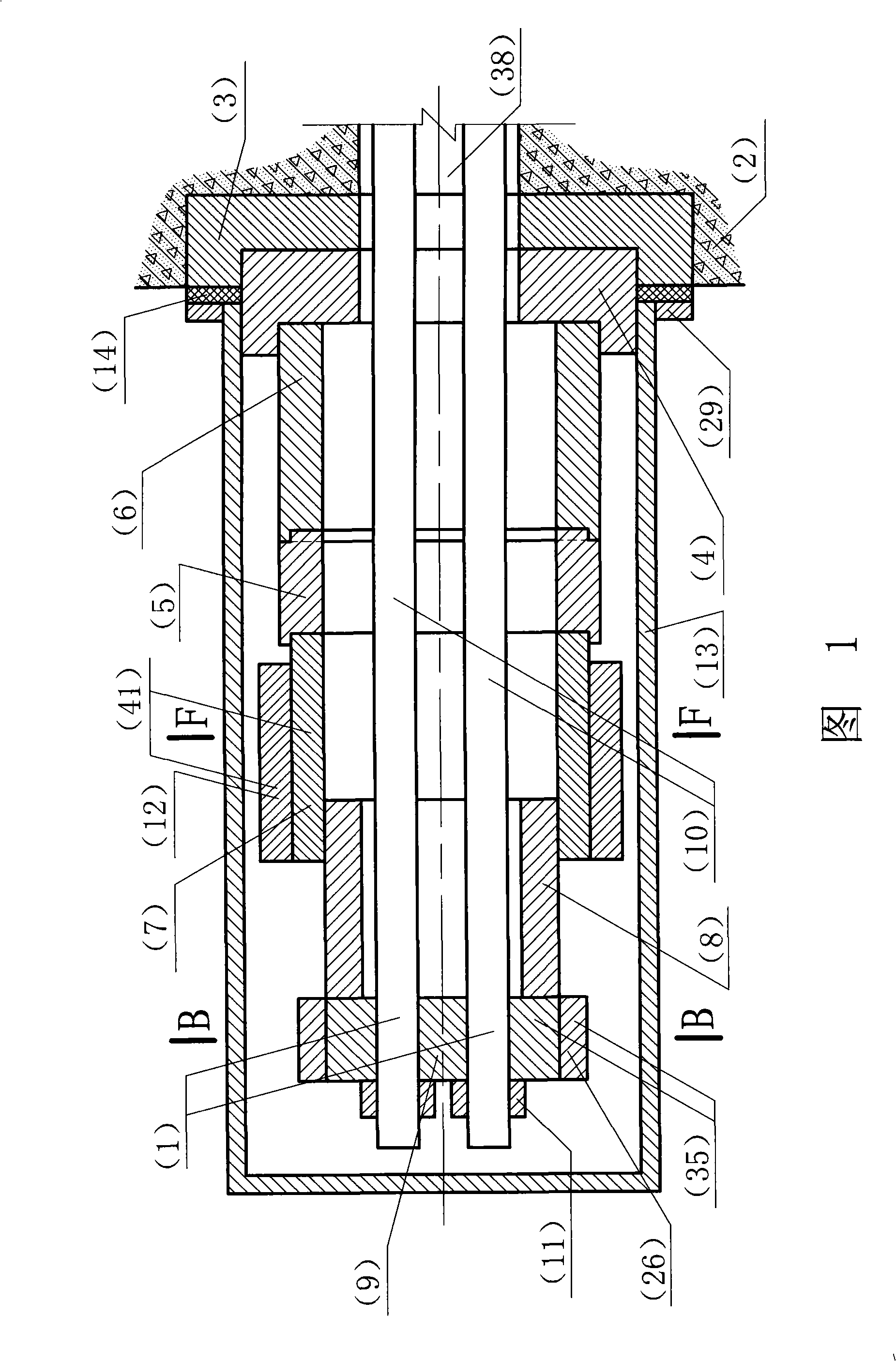

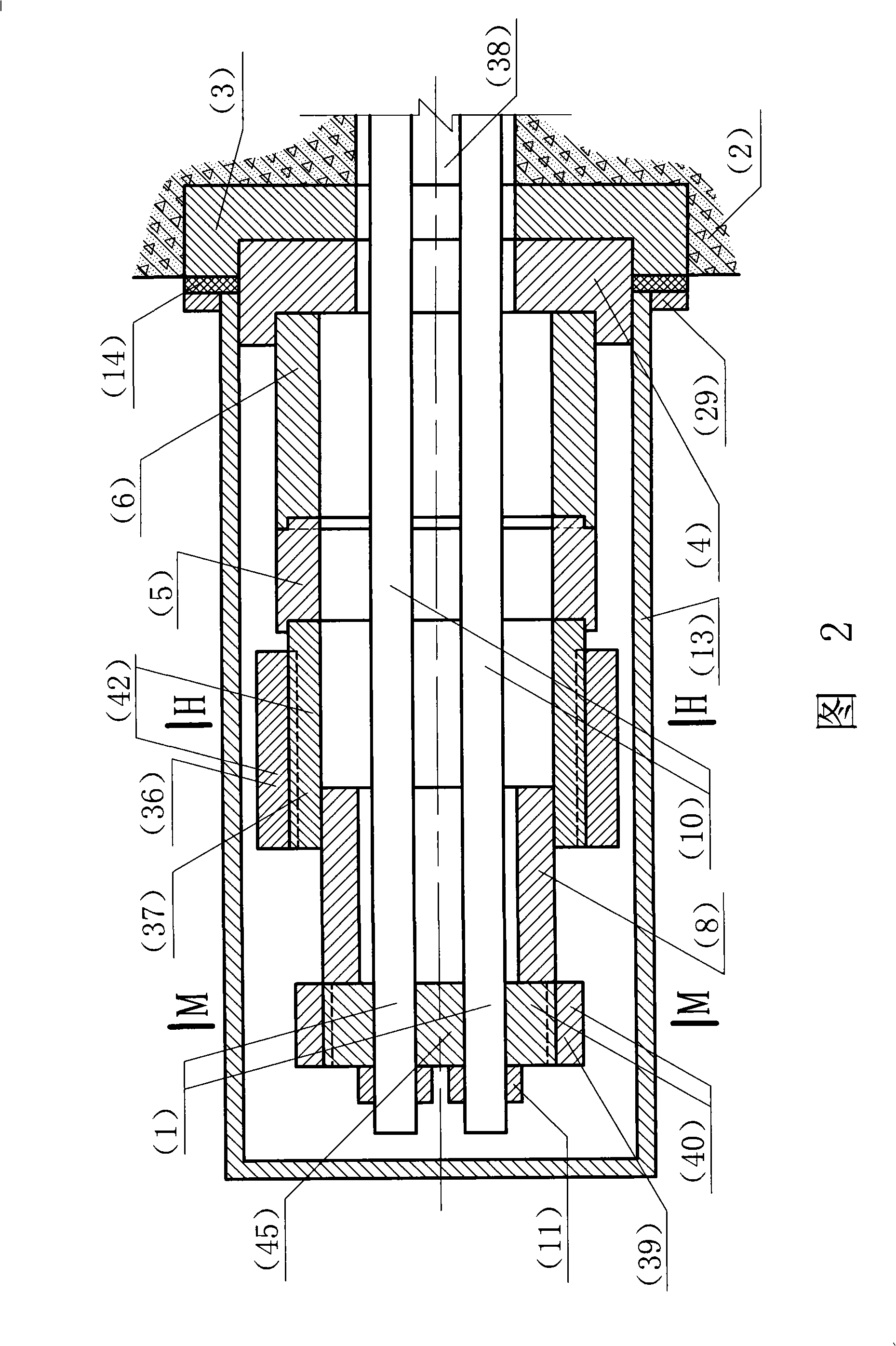

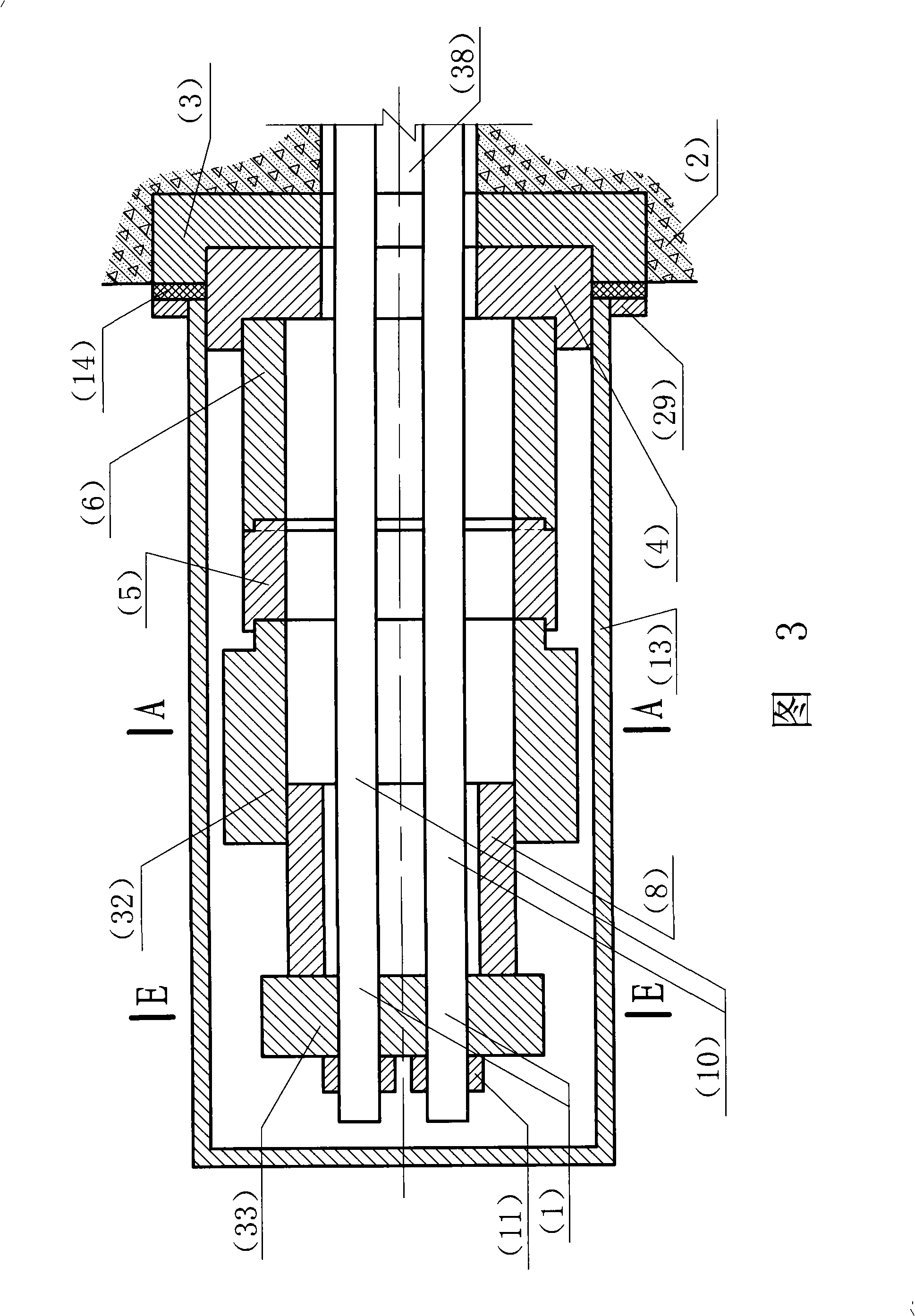

[0050] For the fixed end structures of the 2 types and 6 types of unbonded post-tensioning prestressing systems described in Figures 1 to 6, each structural component is installed at the specified position before the prestressed steel bars are stretched 10 times, and the No. 1 back-tensioning outer tube The internal thread of No. 7 or No. 3 retracting outer pipe 37 or No. 6 retracting part 32 is respectively matched with the external thread of No. 1 retracting inner tube 8, and then positioned with No. 1 prestressed reinforcement positioning plate 35 or No. 3 prestressed reinforcement respectively. The distance of plate 40 or No. 2 prestressed reinforcing bar positioning plate 33 is greater than or equal to the length of anchor clip 18; No. 2 retracts the outer tube 24 or No. 4 retracts the outer tube 47 or the internal thread of No. 5 retracted part 31 and 3 respectively. After the external threads of the No. 2 retreat inner tube 46 and the No. 2 retreat inner tube 21 are matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com