Parameter optimization method of hydraulic turbine speed control system based on satisfaction control

A speed regulation system and satisfactory control technology, which can be used in mechanical equipment, hydroelectric power generation, engine components, etc., and can solve problems such as optimization design difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

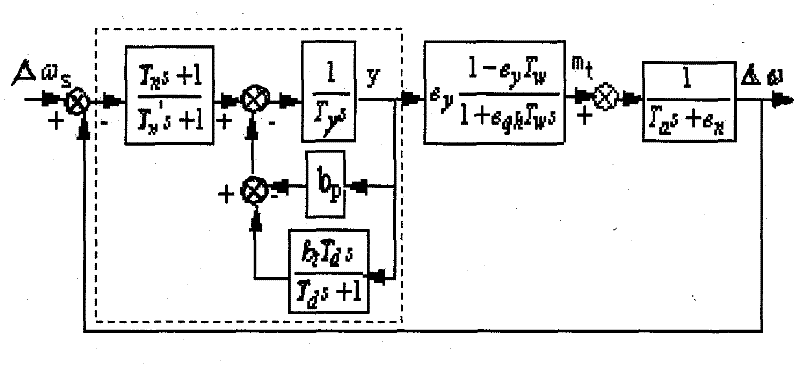

[0093] Example 1: Linear water hammer

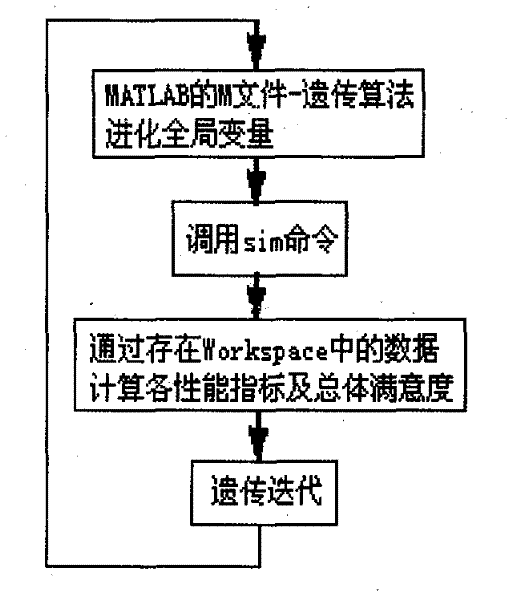

[0094] System structure diagram such as figure 1 Shown. The known number of the system parameters obtained by measurement is: T w =3.0s, e=0.85, e qh = 0.4, e y = 1.1, e n = 1.5, T a =5.0s, T y =0.1s, b p = 0.02. Taking overall satisfaction as the fitness degree, using genetic algorithm, after 12 iterations, the overall satisfaction of the system reaches 1, such as Figure 5 . At this time, the speed control system parameter is T d = 0.88, b t = 0.8645, T n =5.9935.

[0095] Objective function For fitness, after 21 genetic iterations, J reaches the minimum, such as Image 6 , The speed control system parameter is T d =0.1, b t = 2.0935, T n = 5.6065. And the parameter calculated by pole placement method is: T d =3.8, b t = 1.04, T n = 2.2. Substitute these three sets of parameters into figure 1 The system is simulated and obtained as Figure 7 The curve shown. It can be seen from the above simulation results that, since the satisfacto...

Embodiment 2

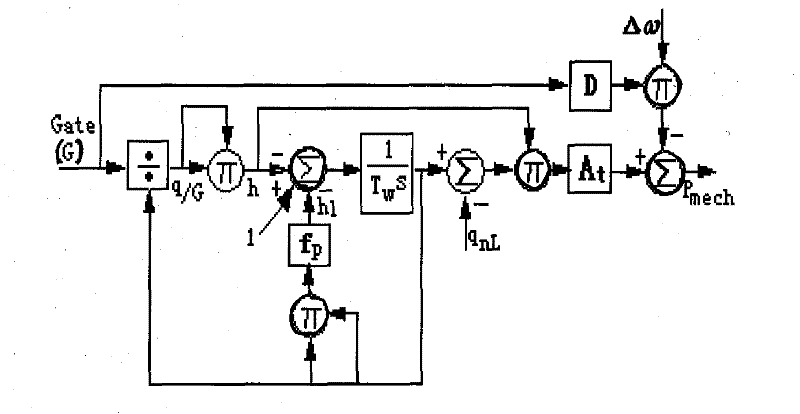

[0096] Example 2: Non-linear rigid water hammer

[0097] Non-linear rigid water hammer model such as figure 2 Shown, the rest of the same figure 1 , The system parameter obtained by measurement is T w =2.3s, f p =0.01, A t =1.004, q nL =0.05, D=0.5, e n = 1.5, T a =5.0s, T y = 0.1s. Taking overall satisfaction as the fitness degree, using genetic algorithm, after 39 iterations, the overall satisfaction of the system reaches 1, such as Figure 8 . At this time, the speed control system parameter is T d =0.197, b t =1.7452, T n = 6.9. Objective function For fitness, after 50 genetic iterations, J reaches the minimum, such as Picture 9 , The speed control system parameter is T d = 0.8798, b t = 0.5572, T n =8.7977.

[0098] According to the data provided by IEEE, T is calculated d =0.75, b t = 0.64, T n = 5.92. Substitute these three sets of parameters into figure 2 The system is simulated and obtained as Picture 10 The curve shown. It can also be seen from the simulation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com