Woven block-blanket and preparation technique

A weaving and crafting technology, applied in the field of woven rugs and its preparation technology, can solve the problems of cumbersome procedures, increased cost of woven rugs, and decreased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

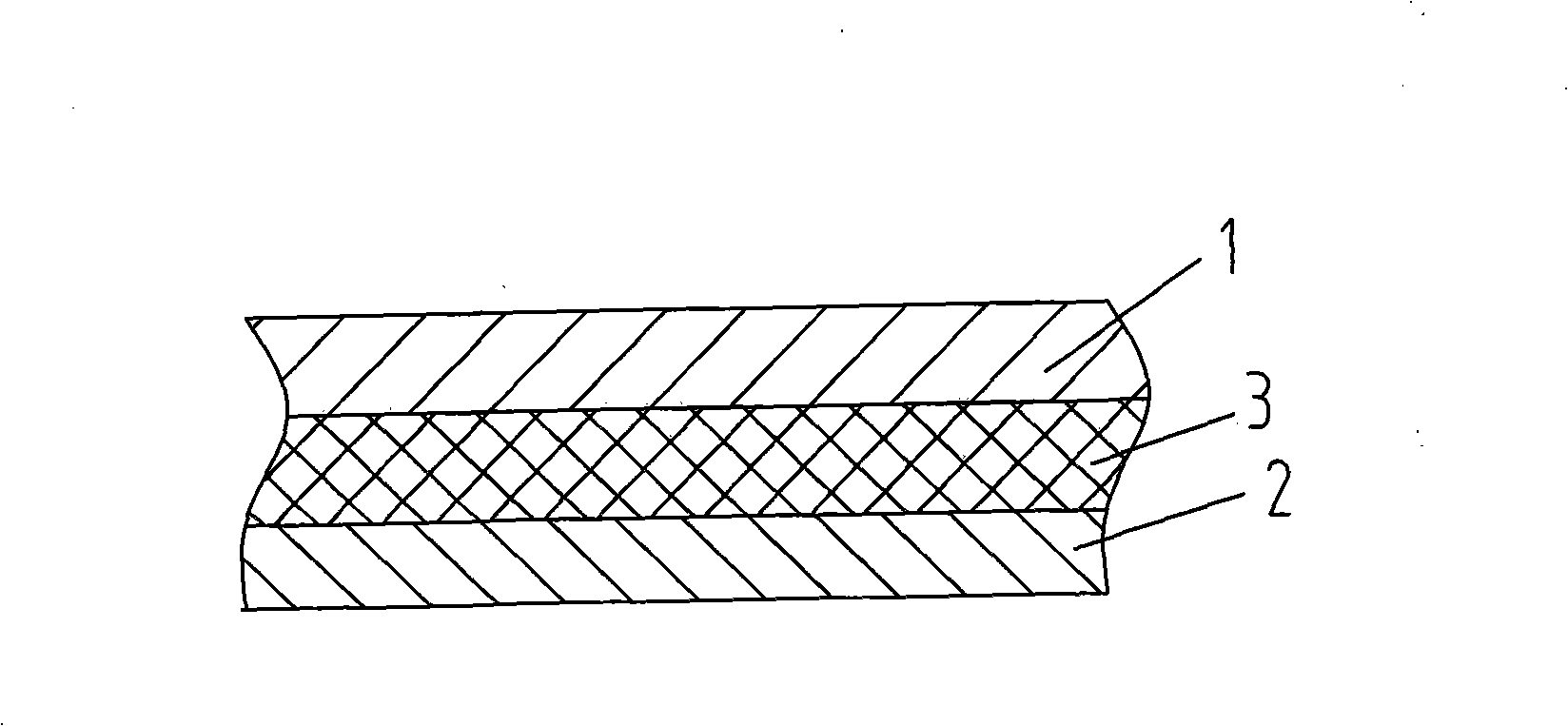

[0016] The present invention will now be described in further detail with reference to the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0017] Such as figure 1 The shown woven carpet includes a tufted layer 1 and a substrate layer 2. The tufted layer 1 is adhered to the substrate layer 2 by an adhesive 3, and the tufted layer 1 and the adhesive are formed in sequence. Layer 3 and substrate layer 2. Among them, the material of the substrate layer 2 is made of fiber material, and the substrate layer 2 is relatively stable, and will not expand and contract with heat. Such a finished woven carpet will not be affected by temperature to cause expansion and contraction with heat. Adhesive 3 material is made of ethylene vinyl acetate copolymer made of hot melt. The above ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com