Scallop seed automatic allocation cage loading device

A technology of automatic distribution and cage filling machine, which is applied in fish farming, application, climate change adaptation and other directions, can solve the problems of inability to meet the needs of productivity, inability to achieve uniform distribution, high labor intensity, etc., to achieve low manufacturing costs, It is convenient for large-scale promotion and application, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

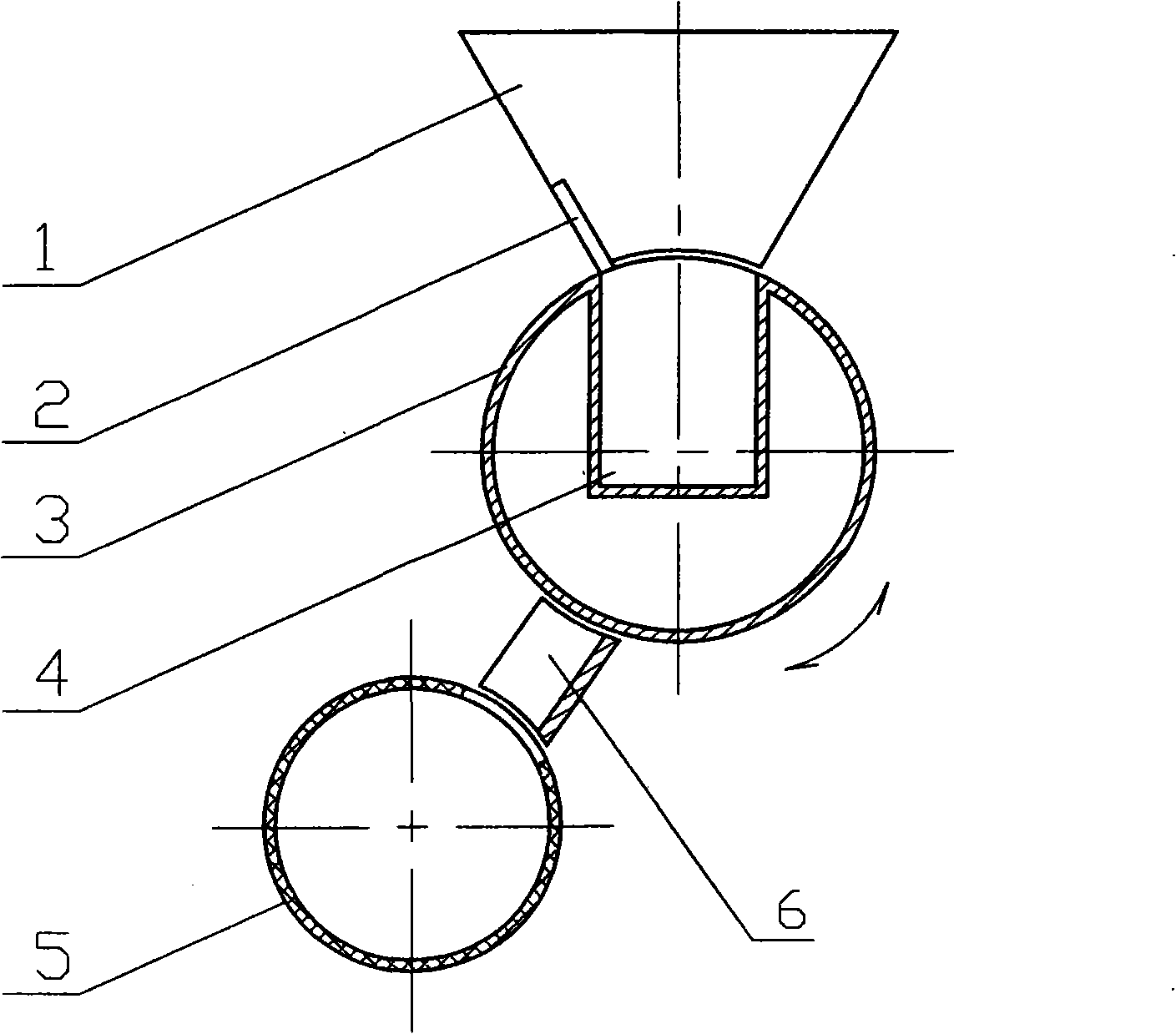

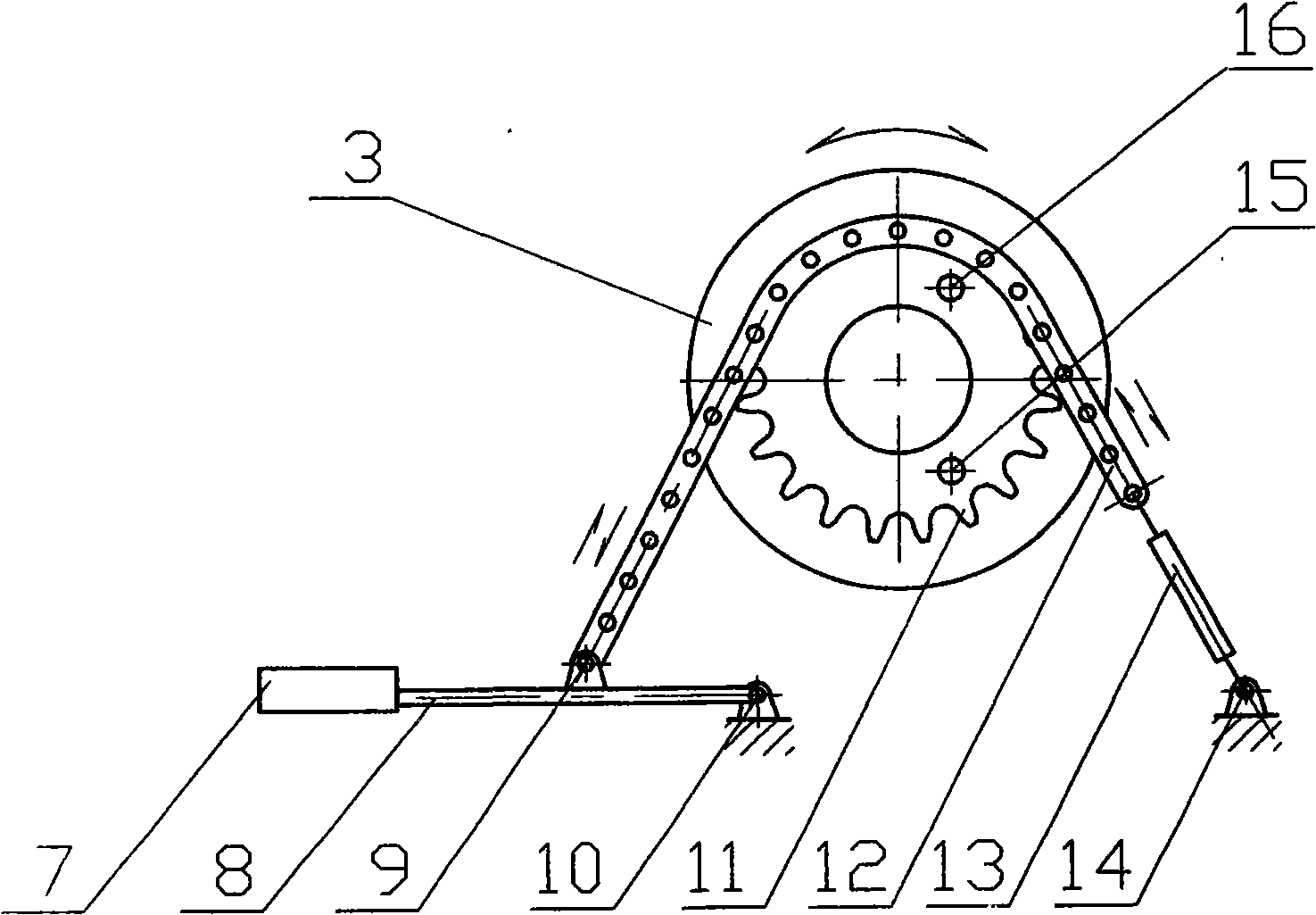

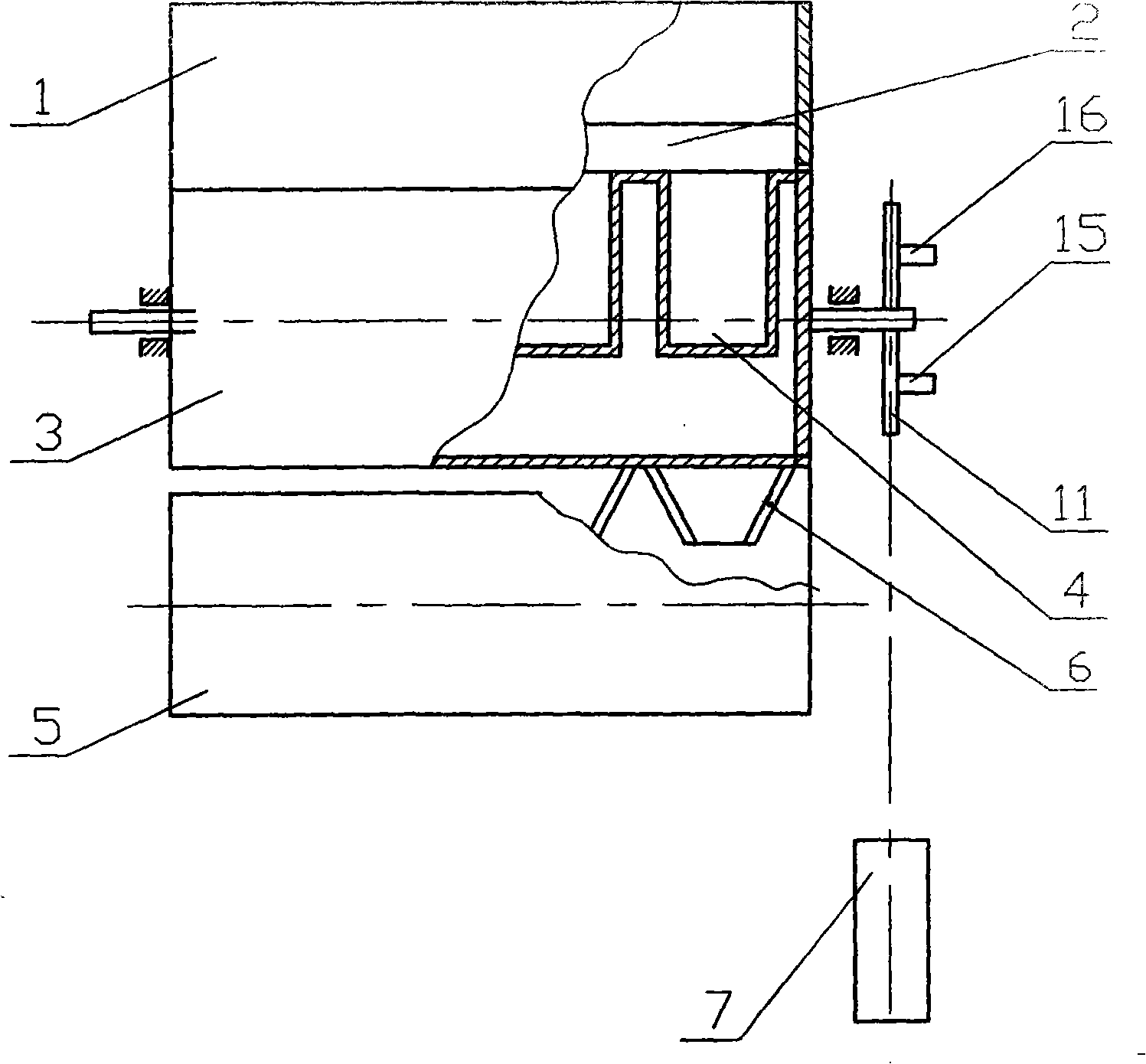

[0014] Such as figure 1 , 3 As shown, the present embodiment includes a hopper 1 and a scallop cage 5 . Hopper 1 is fixedly installed on the frame, and scallop cage 5 is hung on the frame by ropes at two ends. On the frame, a distribution roller 3 is also installed through a bearing mechanism. The square holes correspond to the number of distribution boxes 4 of the same size. The installation method of the distribution box 4 is: the box body is sunk in the inner cavity of the cylinder, and the opening edge of the box is welded on the cylinder wall. Below the hopper 1, several feeding partitions 6 fixed on the frame are divided into several feeding passages. The upper ports of these feeding passages correspond to the positions of the above-mentioned distribution boxes 4. The positions of the openings of each breeding space of the cage 5 are corresponding. On the inner wall of the hopper 1, a row of brushes 2 with the hair ends facing down are fixedly installed, and the bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com