Mechanical type anti-fall device capable of ascending scaffold

A scaffolding and mechanical technology, applied in the field of mechanical anti-falling devices, can solve the problems of troublesome processing, high cost, affecting the anti-falling reliability of the anti-falling device, etc., and achieve the effects of convenient installation and implementation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

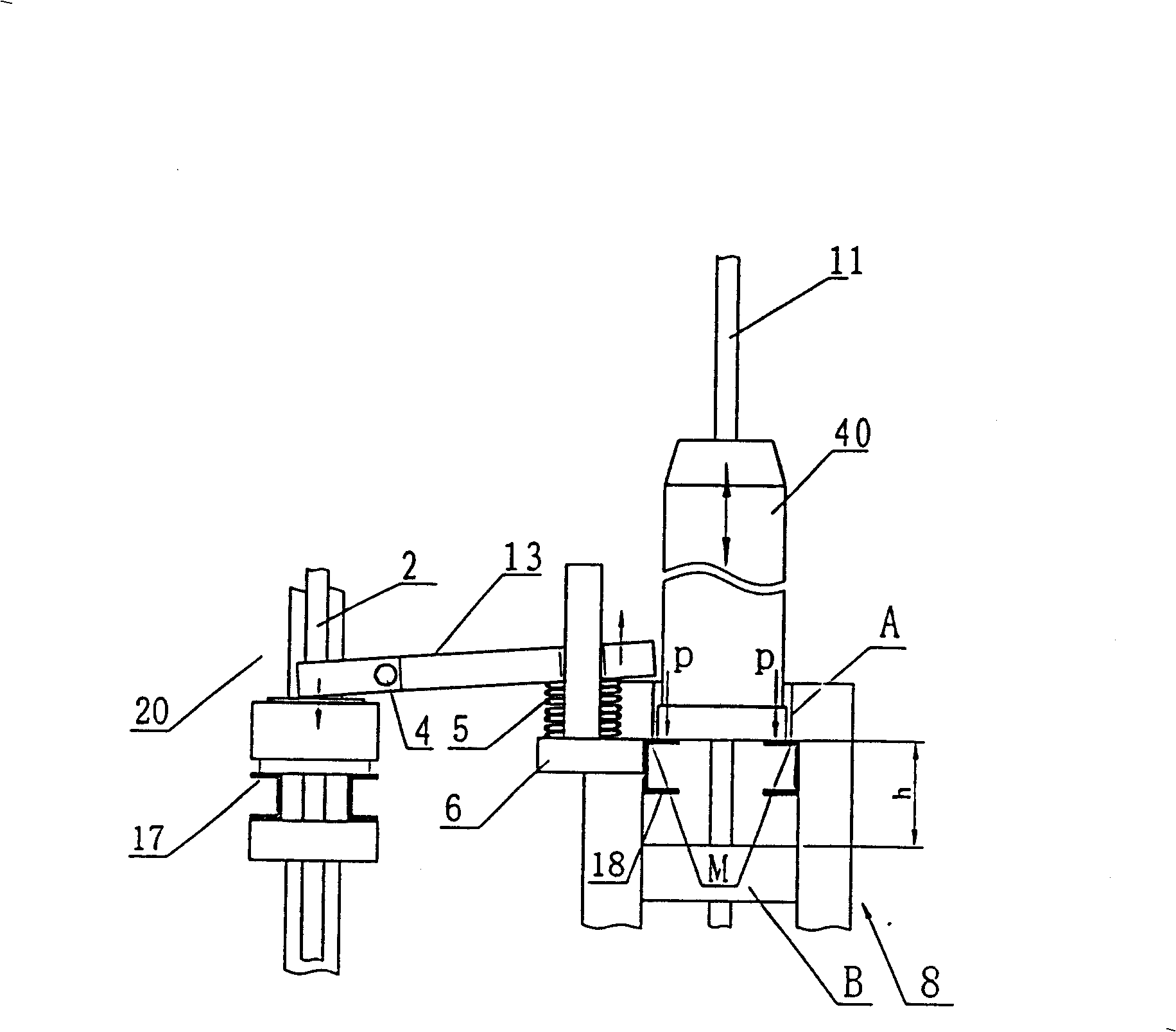

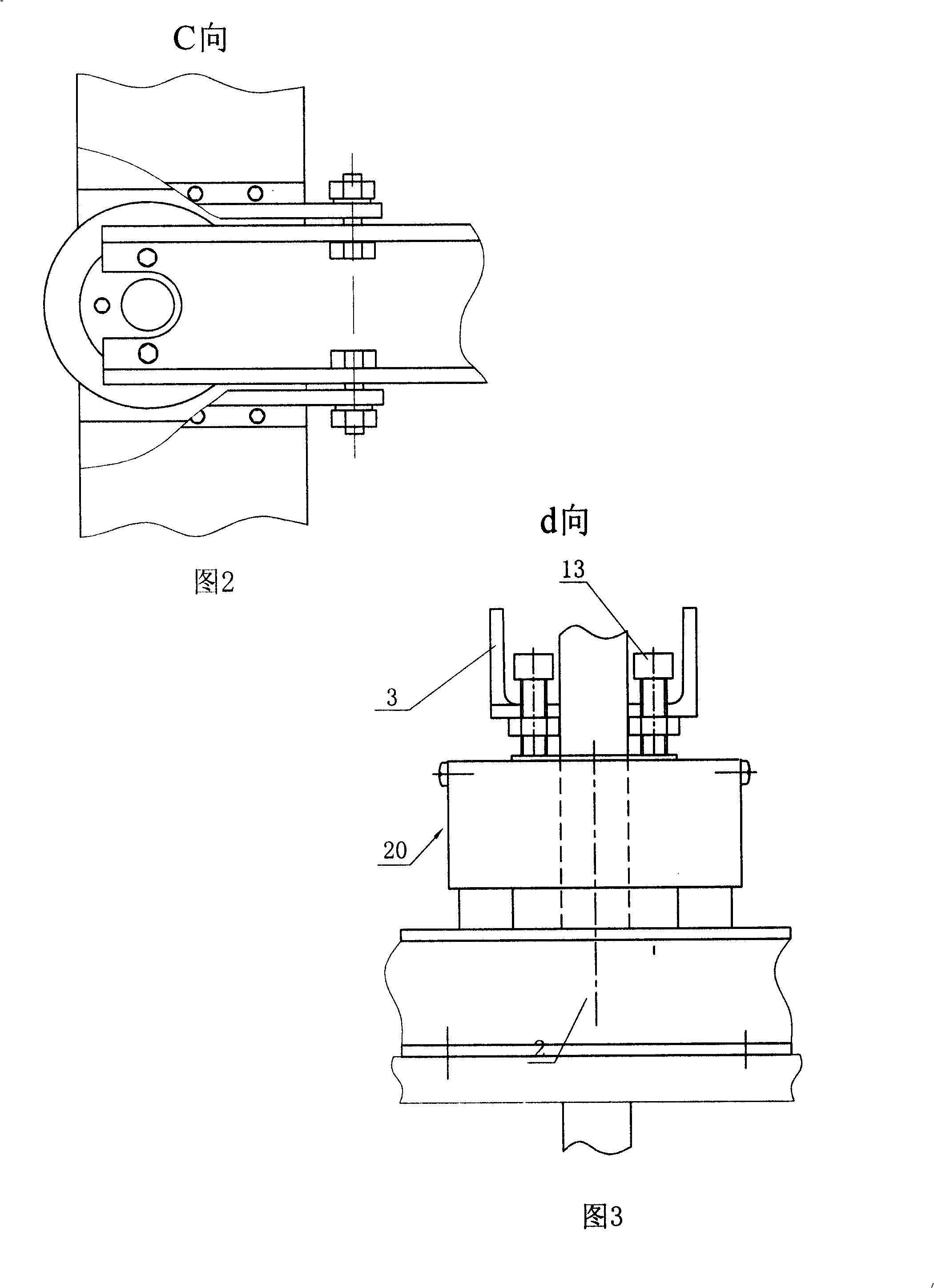

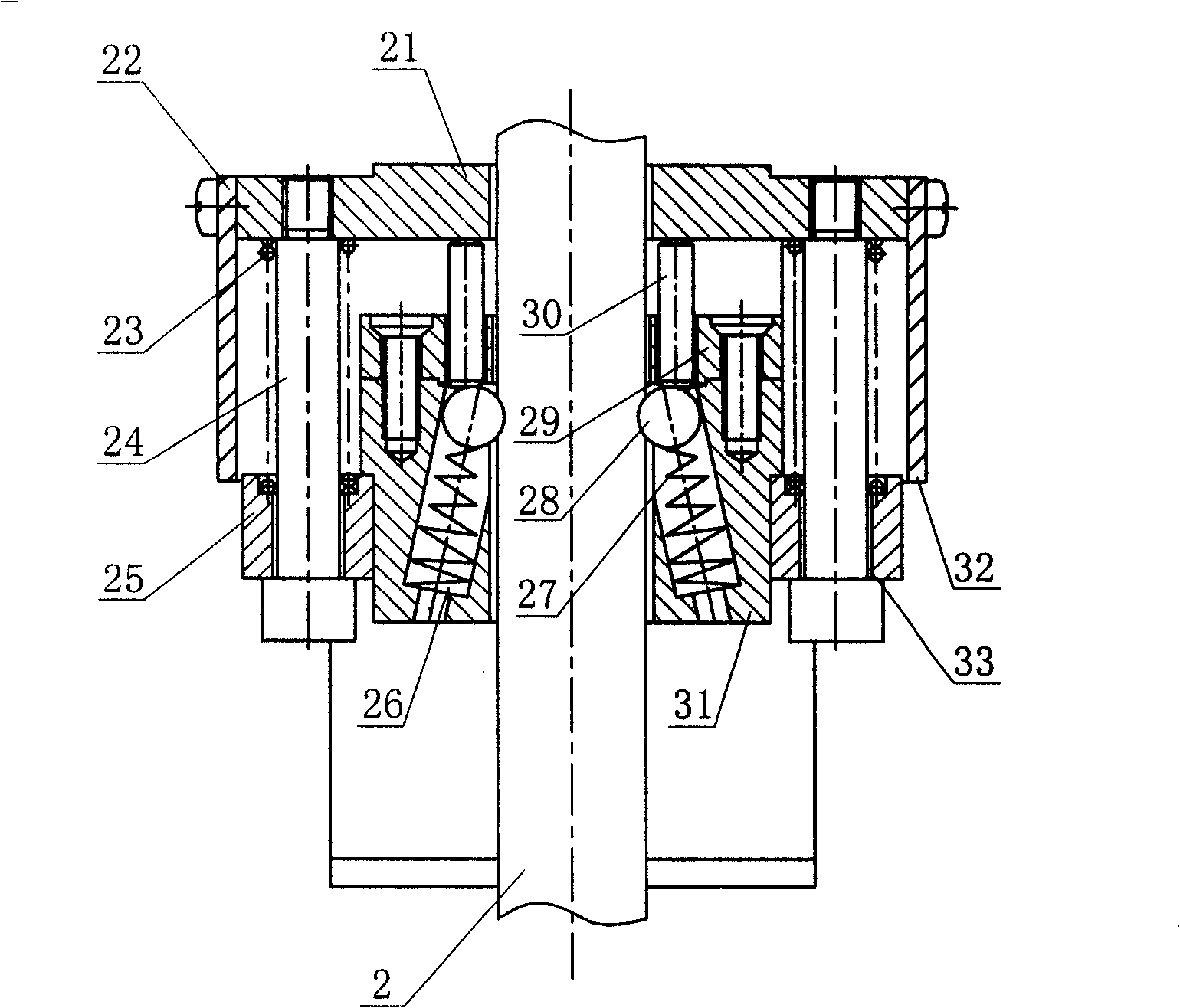

[0023] control figure 1 , Fig. 2, Fig. 3, anti-fall device of the present invention is mainly made up of compression spring 5, compression spring supporting plate 6, stressed cross bar 9, lever 3, anti-fall pull bar 2 and locking mechanism 20. The anti-drop rod 2 is arranged and fixed on the supporting beam frame 51 on the building structure 50 . The locking mechanism 20 is connected on the anti-falling pull rod 2, and its both sides are connected with the channel steel 17, and are fixed on the scaffold 7 by the channel steel 17 (see also Fig. 2, Fig. 3). The locking mechanism 20 can be locked or released on the anti-drop pull bar. The hoisting equipment is a jack 40, which is installed on the hoisting equipment stress bracket 8 of the scaffolding 7, and is connected to the hoisting equipment stress rod 11. Tightly on the support beam frame 51. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com