Manual key miller

A pit pattern and key technology, which is applied in the field of key pit pattern planer, can solve the problems of metal chips flying out, complicated structure, operation limitation, etc., and achieves the effects of small space, simple use method, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

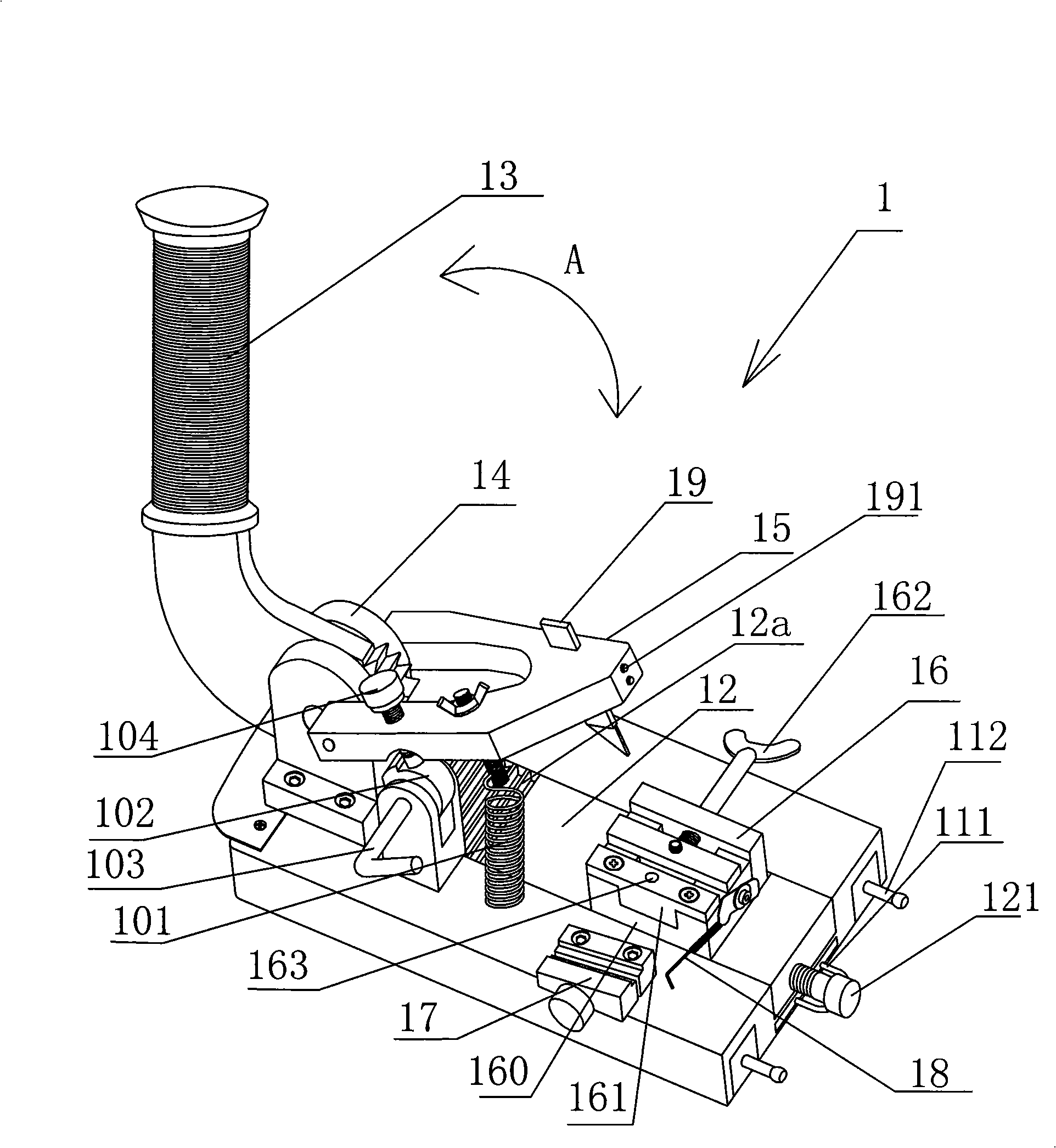

[0021] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0022] refer to figure 2 and image 3 , for illustrative purposes, the figure 2 and image 3 The direction toward the handle is defined as the rear, the direction opposite to the handle is defined as the front, and the direction perpendicular to the front-rear direction is defined as the left-right direction.

[0023] According to the embodiment of the present invention, the manual key pit pattern planer 1 is generally composed of a base 11, a tooth plate 12, a handle 13, a connecting bracket 14, a knife rest 15, a movable clamp 16, a fixed fixture 17 and a pit pattern position indicating needle 18. and so on.

[0024] The pedestal 11 is usually a cuboid seat body, and the weight is relatively large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com