Method for depositing atomic layer and semiconductor device formed by the same

一种原子层沉积、半导体的技术,应用在半导体器件、半导体/固态器件制造、电固体器件等方向,能够解决原子岛尺寸分布均匀性差等问题,达到原子尺寸大小均匀一致的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides an atomic layer deposition method, refer to the attached Figure 13 The shown process flow chart comprises the following steps:

[0054] Step S200, placing a semiconductor substrate in the atomic layer deposition chamber;

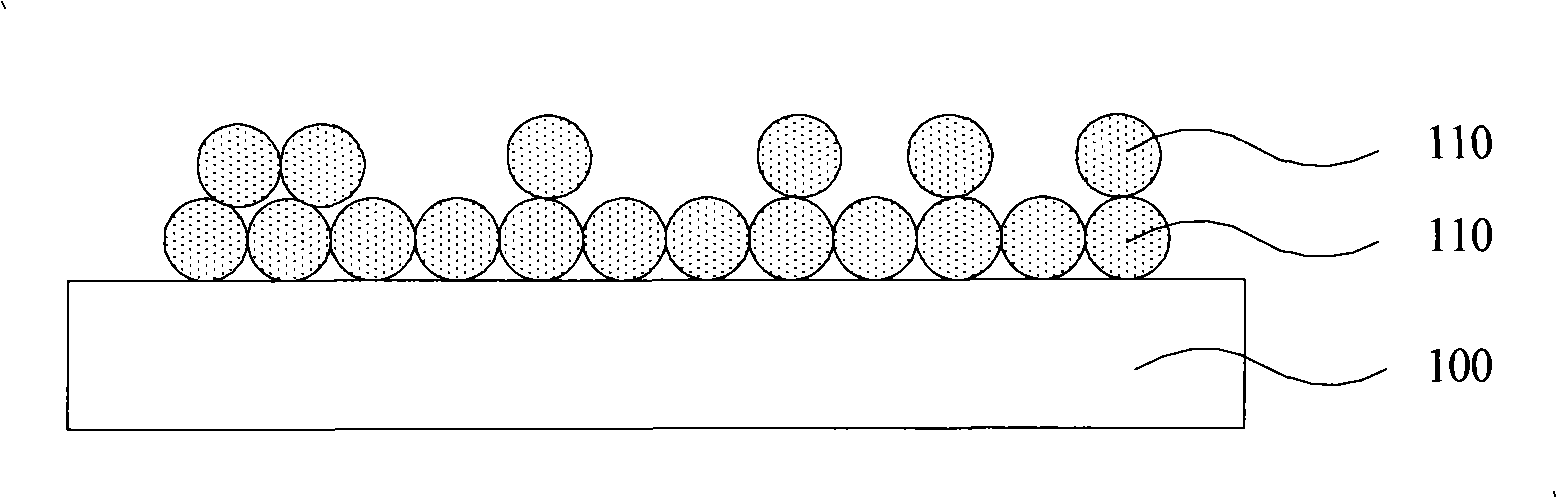

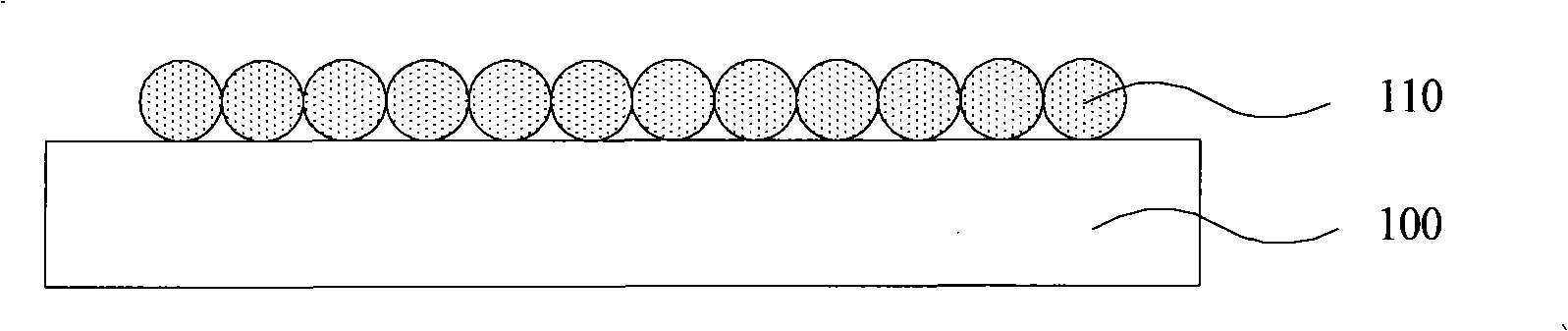

[0055] Step S201, the first precursor gas flows to the semiconductor substrate in the atomic layer deposition chamber to form a discretely distributed first monolayer on the semiconductor substrate;

[0056] Step S202, the inert purge gas flows to the atomic layer deposition chamber to remove the first precursor gas that does not form the first monolayer;

[0057] Step S203, the second precursor gas flows to the atomic layer deposition chamber, and reacts with the first precursor gas forming the first monolayer to form a discrete first compound monolayer;

[0058] Step S204, the inert purge gas flows to the atomic layer deposition chamber to remove the second precursor gas that has not reacted with the first precursor gas a...

Embodiment approach

[0085] As a specific implementation manner, the second precursor gas may be a substance containing N atoms or O atoms or metal atoms, used as a reducing agent or an oxidizing agent. The substance containing N atoms or O atoms or metal atoms is, for example, NH 3 or O 2 .

[0086] Just as an example, this embodiment provides several specific second precursor gases, so that those skilled in the art can better understand and implement the present invention. If the finally formed discrete distribution of the first compound monolayer is Si 3 N 4 , then the first precursor gas is a reaction gas with a Si atom nucleating body substance, and the second precursor gas is a gas capable of reacting with the first monolayer nucleating body formed by the first precursor gas to form a compound monolayer, By way of example only, the second precursor gas could be NH 3 , N 2 O, N 2 Wait for gas.

[0087] If the finally formed discrete distribution of the first compound monolayer is SiO ...

Embodiment 2

[0129] This embodiment provides an atomic layer deposition method, refer to the attached Figure 20 Process flow chart, including the following steps:

[0130] Step S300, placing a semiconductor substrate in the atomic layer deposition chamber;

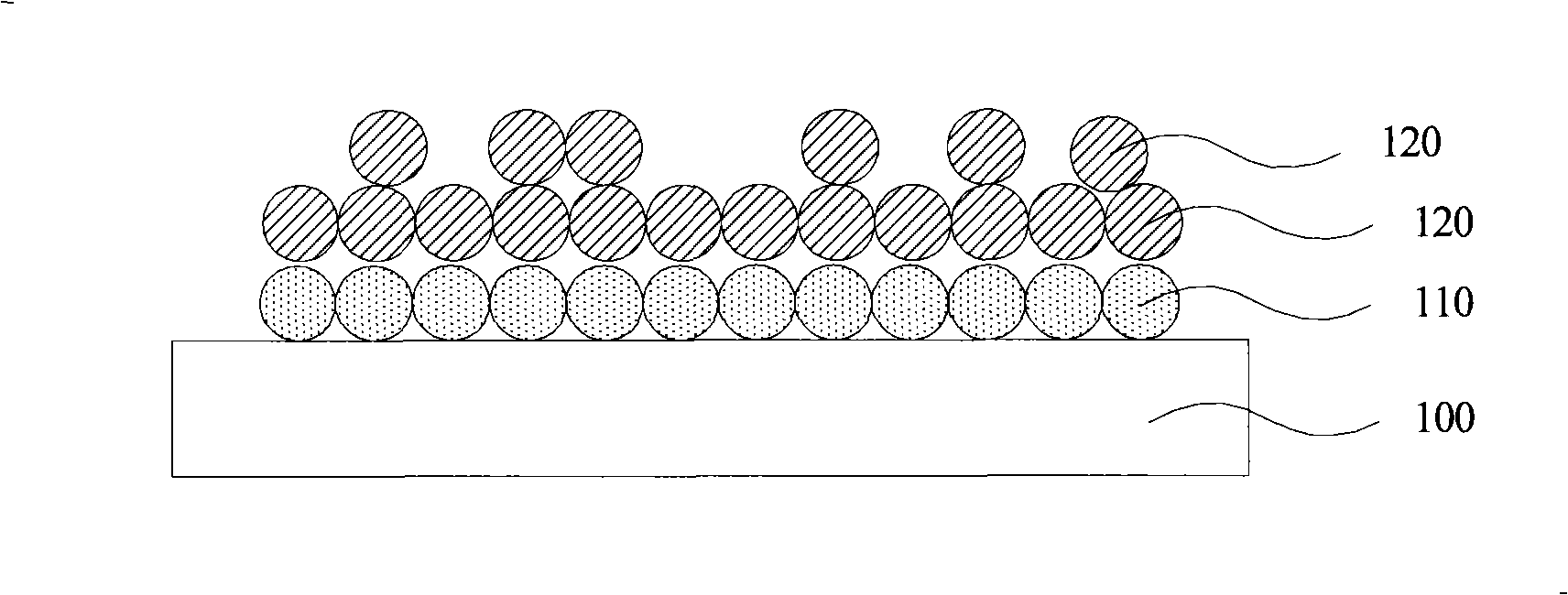

[0131] Step S301, the first precursor gas flows to the semiconductor substrate in the atomic layer deposition chamber to form a discretely distributed first monolayer on the semiconductor substrate;

[0132] Step S302, the inert purge gas flows to the atomic layer deposition chamber to remove the first precursor gas that does not form the first monolayer;

[0133] Step S303, the second precursor gas flows to the atomic layer deposition chamber, and reacts with the first precursor gas forming the first monolayer to form a discrete first compound monolayer;

[0134] Step S304, the inert purge gas flows to the atomic layer deposition chamber to remove the second precursor gas that has not reacted with the first monolayer and by-product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com