Method for leveling turntable

A technology of turntable and tabletop, which is applied to the parts of the instrument, instruments, etc., to achieve the effect of high leveling accuracy and adaptation to harsh environment changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the method of the present invention is described in further detail.

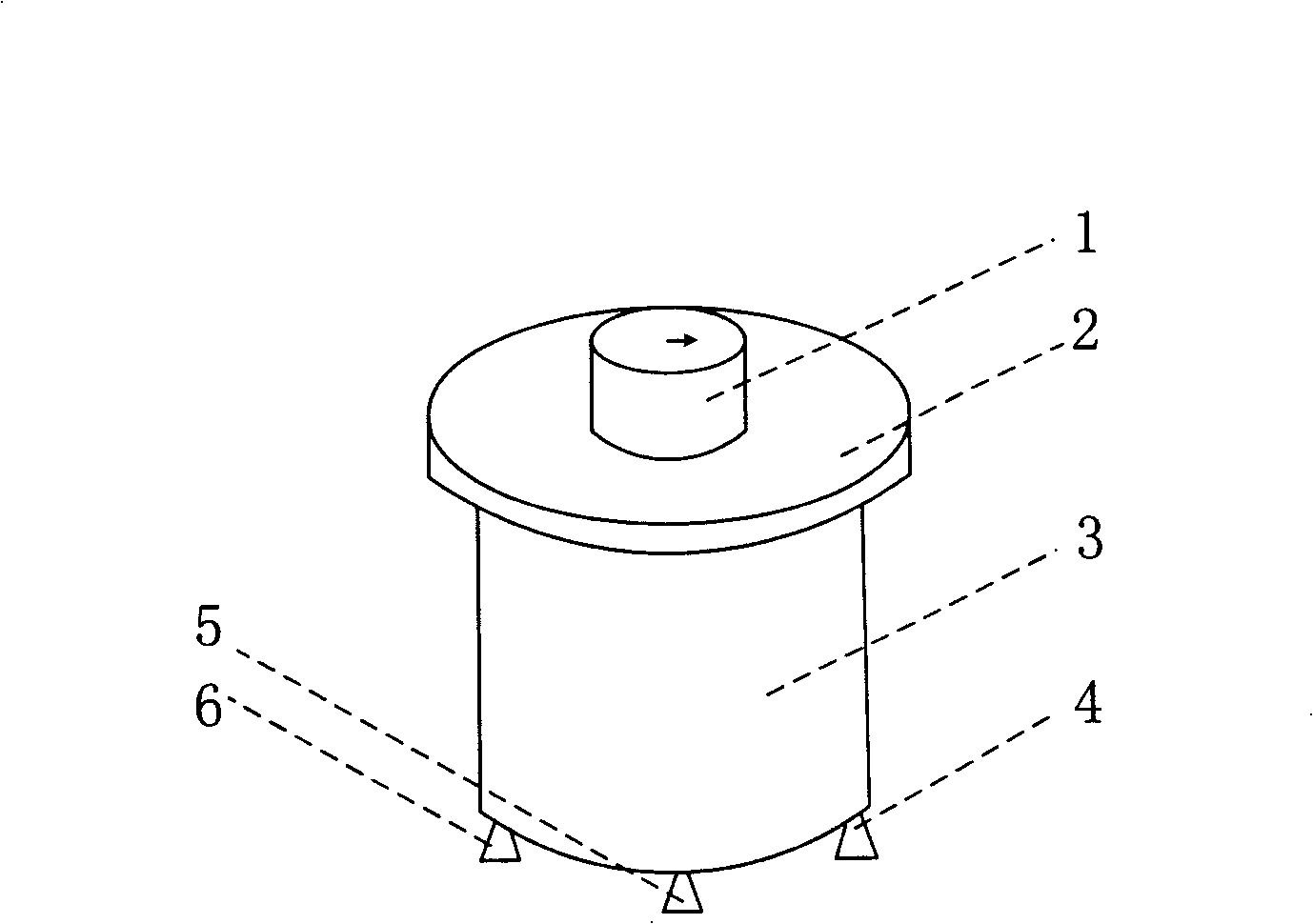

[0019] A kind of theodolite turntable is carried out leveling by the method of the present invention, with the inclinometer as test tool, press figure 1 As shown, set the inclinometer 1 at the center of the turntable surface 2 to be leveled, so that the test axis of the inclinometer is parallel to the turntable surface, and perform leveling according to the following steps:

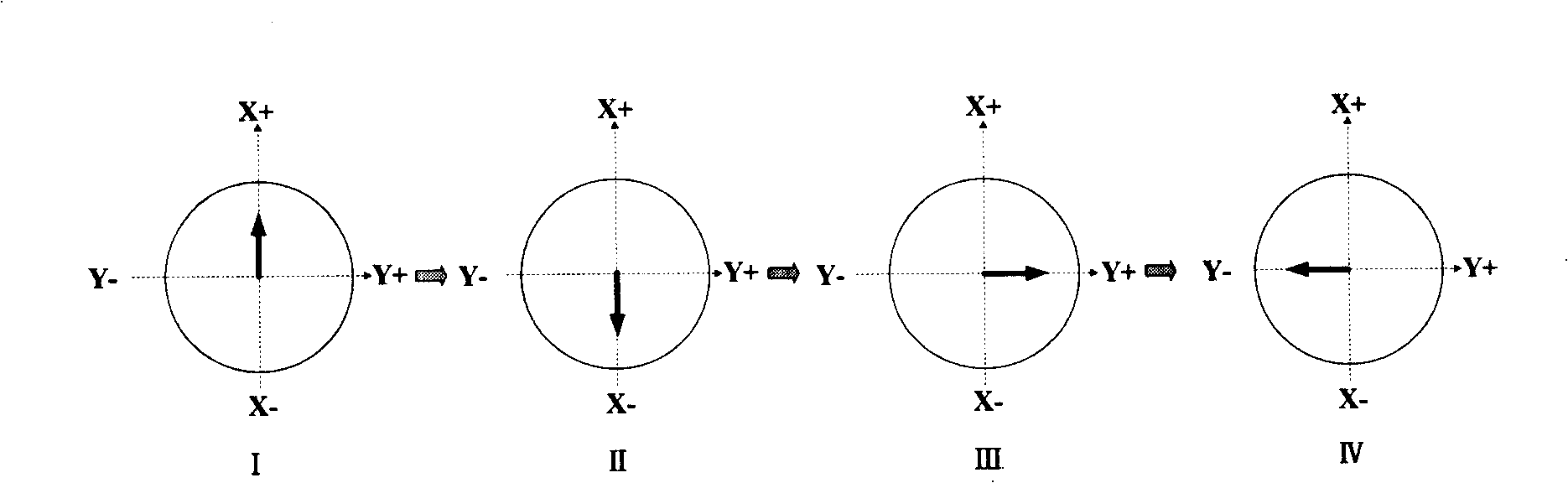

[0020] a. Turn the inclinometer to the initial position I where its test axis is parallel to the line between the two height adjustment mechanisms 4 and 6 under the turntable base 3 (such as figure 2 Shown in I), record the inclination angle value of the test shaft output when the inclinometer is at the initial position I X+ ;

[0021] b. Turn the inclinometer 180° together with the turntable to position II (such as figure 2 II), record the inclination angle value of the test shaft output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com