Door for closing a washing machine or a tumble dryer

A technology for washing machines and clothes dryers, which is applied to other washing machines, applications, washing devices, etc., and can solve the problems of complex hinge manufacturing, large weight, and heavy hinges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

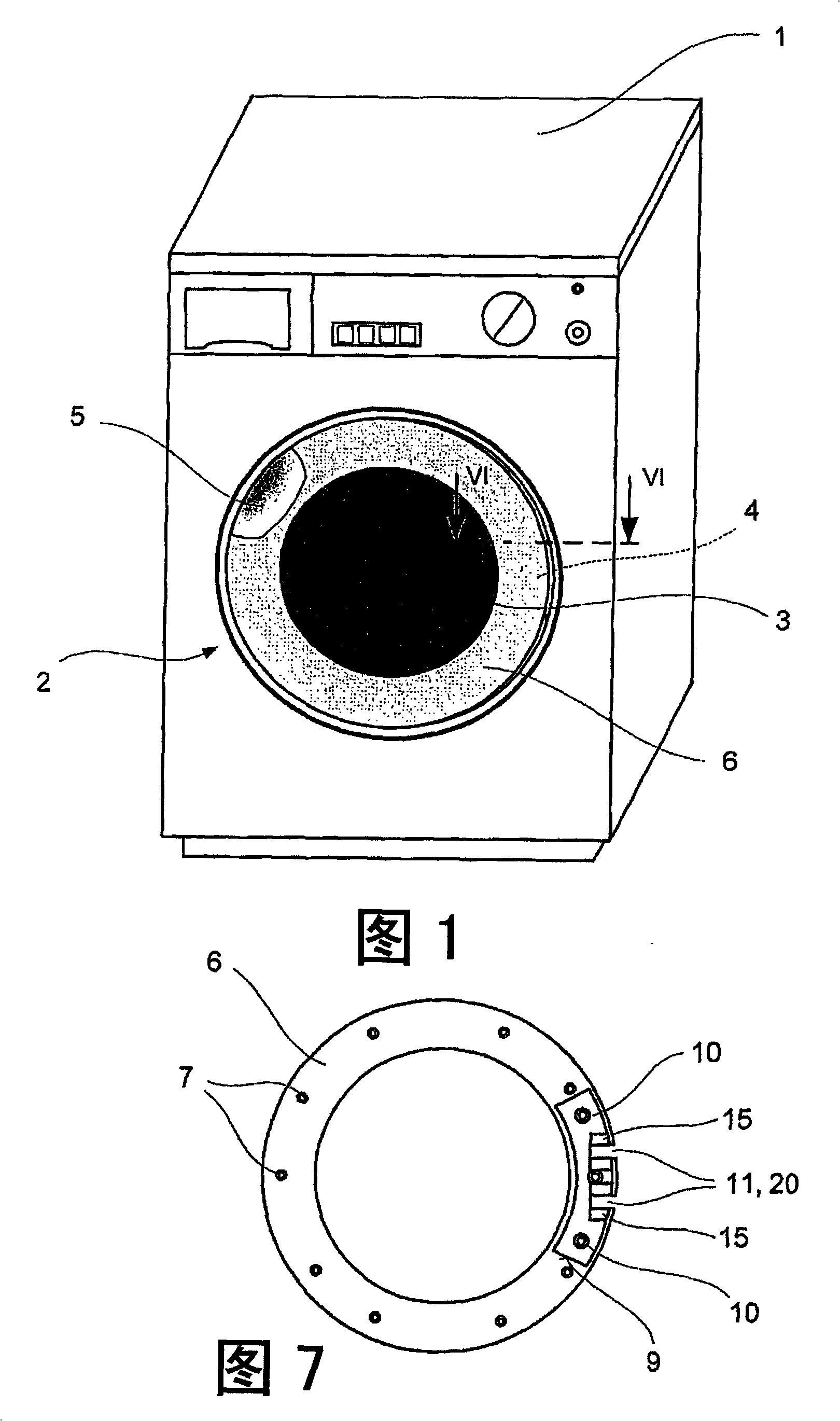

[0026] Figure 1 shows a housing 1 of a tumble dryer, which is loadable from the front side and has a door 2 which is pivotally hinged on one side. The door 2 for closing the load port comprises a two-part plastic frame 6 with a recessed glass window 3 . The door 2 is hinged to the appliance housing 1 by means of a hinge 4 . Opposite the hinge 4 , the integrally formed door handle 5 is offset upwards in the edge region of the frame 6 . When the door 2 is pivoted, the edge 22 tilts behind the hinge arm ( 21 , FIG. 6 ), so that the hinge arm 21 protrudes into the slot 23 of the edge 22 .

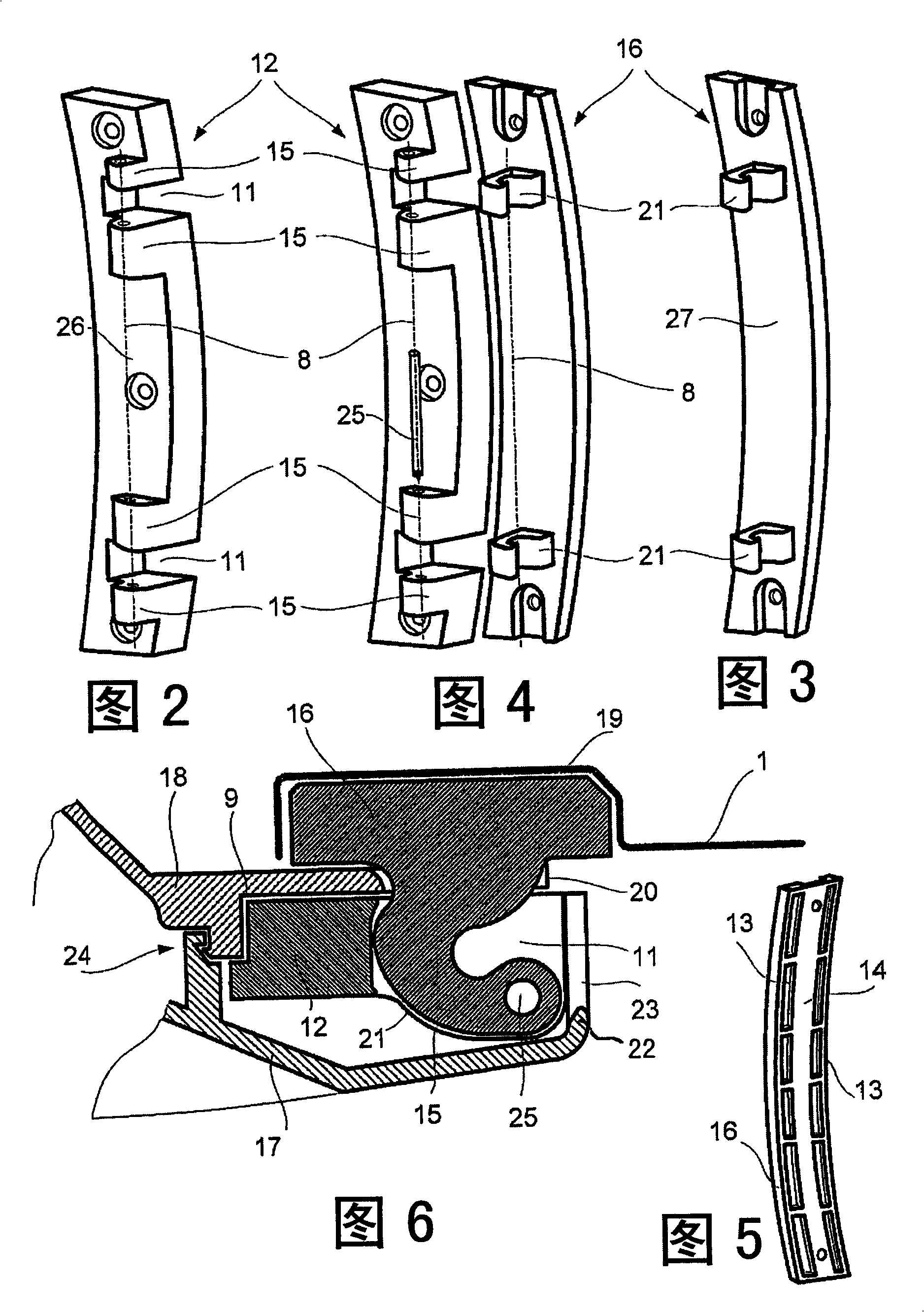

[0027] According to FIGS. 2 to 4 , the hinge 4 comprises two parts, the door-side hinge part 12 and the appliance-side hinge part 16 , which are connected to one another via only one axis of rotation 8 . The axis of rotation 8 of the hinge 4 divides into two. The crescent-shaped base plate 26 of the door-side hinge part 12 traverses the transverse opening 11 ( FIG. 7 ) in the door frame 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com