Construction method for hanging wide span arcuated open-web beam

A construction method and technology of hollow beams, which are applied in construction, building structure, processing of building materials, etc., can solve the problems of inability to hoist in place, many high-altitude operations, and long installation period, so as to improve construction safety and ensure construction quality. , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

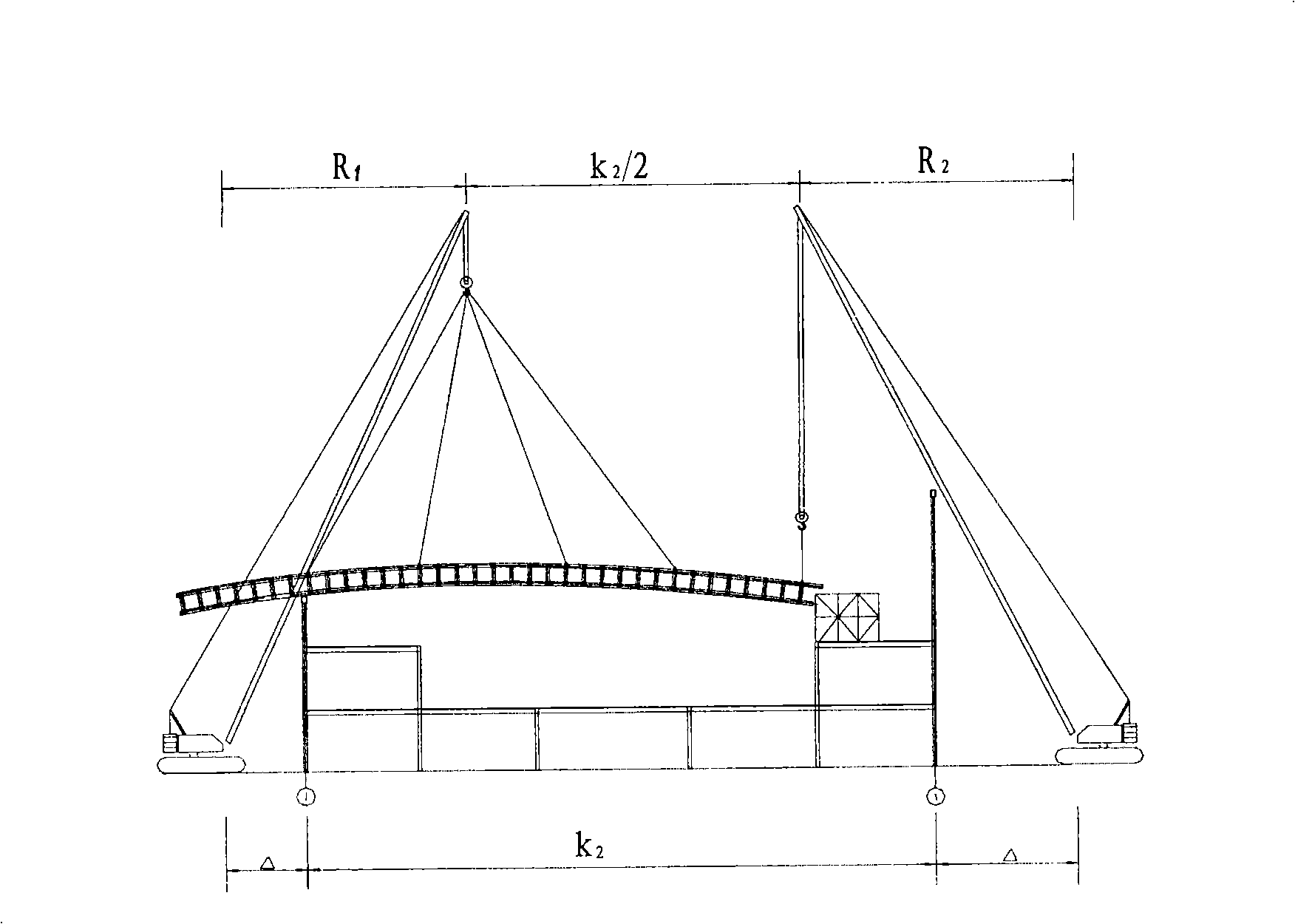

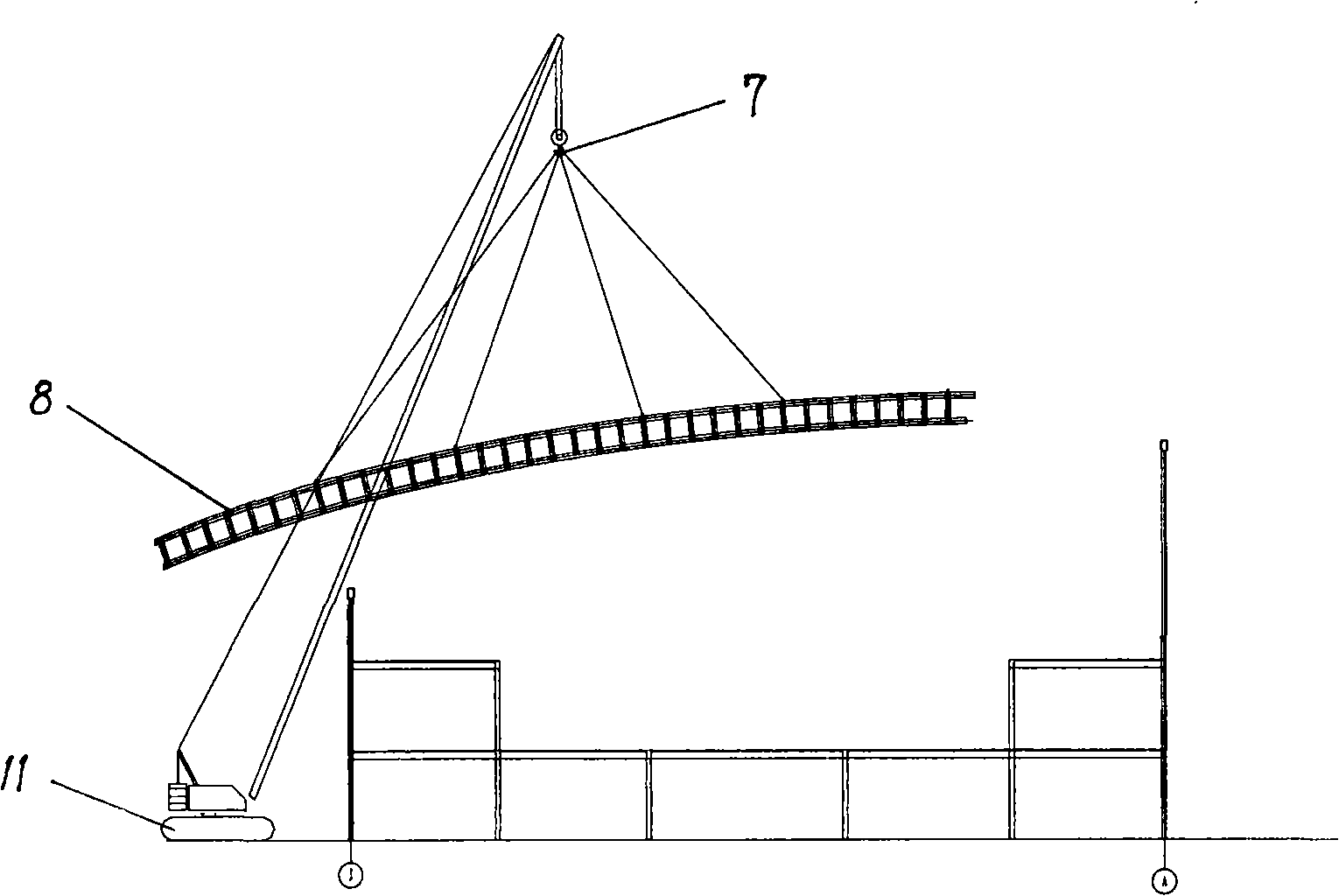

[0036] The invention relates to a construction method for hoisting a large-span curved steel structure vierendeel beam used for building an ellipsoidal roof. Its specific steps are:

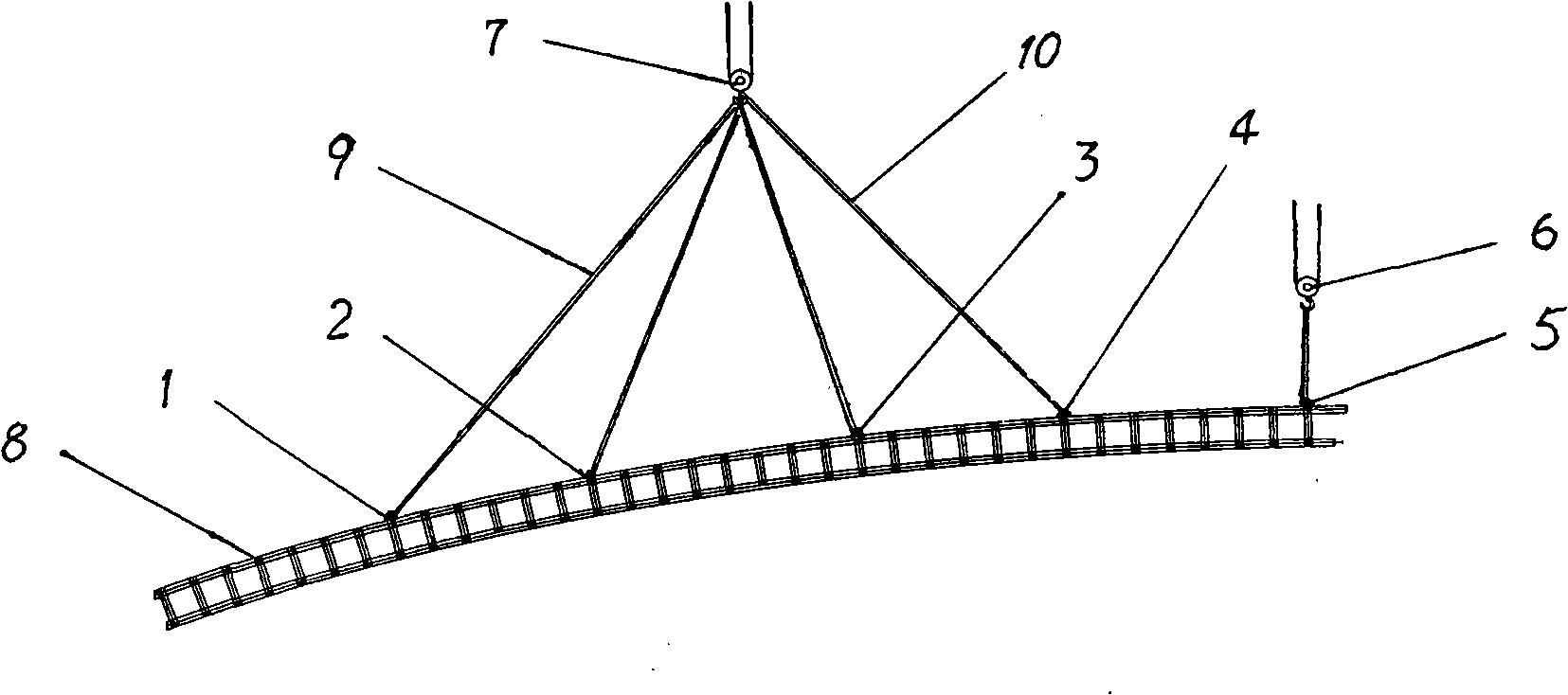

[0037] (1) Assembly of hollow beams, arrangement of lifting lugs and tying of lifting ropes.

[0038] After the hollow beam is manufactured in sections in the factory, it is transported to the construction site outside the span of the building, and the overall assembly pretreatment of the large-span steel structure hollow beam is carried out at the lifting position. The assembly pretreatment of the hollow beam is to weld and assemble the hollow beam made in sections at the lifting position into a whole, and paint it after passing the flaw detection inspection.

[0039] After the assembly is completed, press on the upper chord of the hollow beam 8 figure 2 Five lugs (1-5) are welded in the locations shown. Among them, the four lifting lugs No. 1-4 are distributed in the length direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com