Novel aluminum cell structure

An aluminum electrolytic cell and electrolytic cell technology, which is applied in the field of new aluminum electrolytic cell structure, can solve problems such as retention, achieve parameter balance, reduce pole distance voltage drop, and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

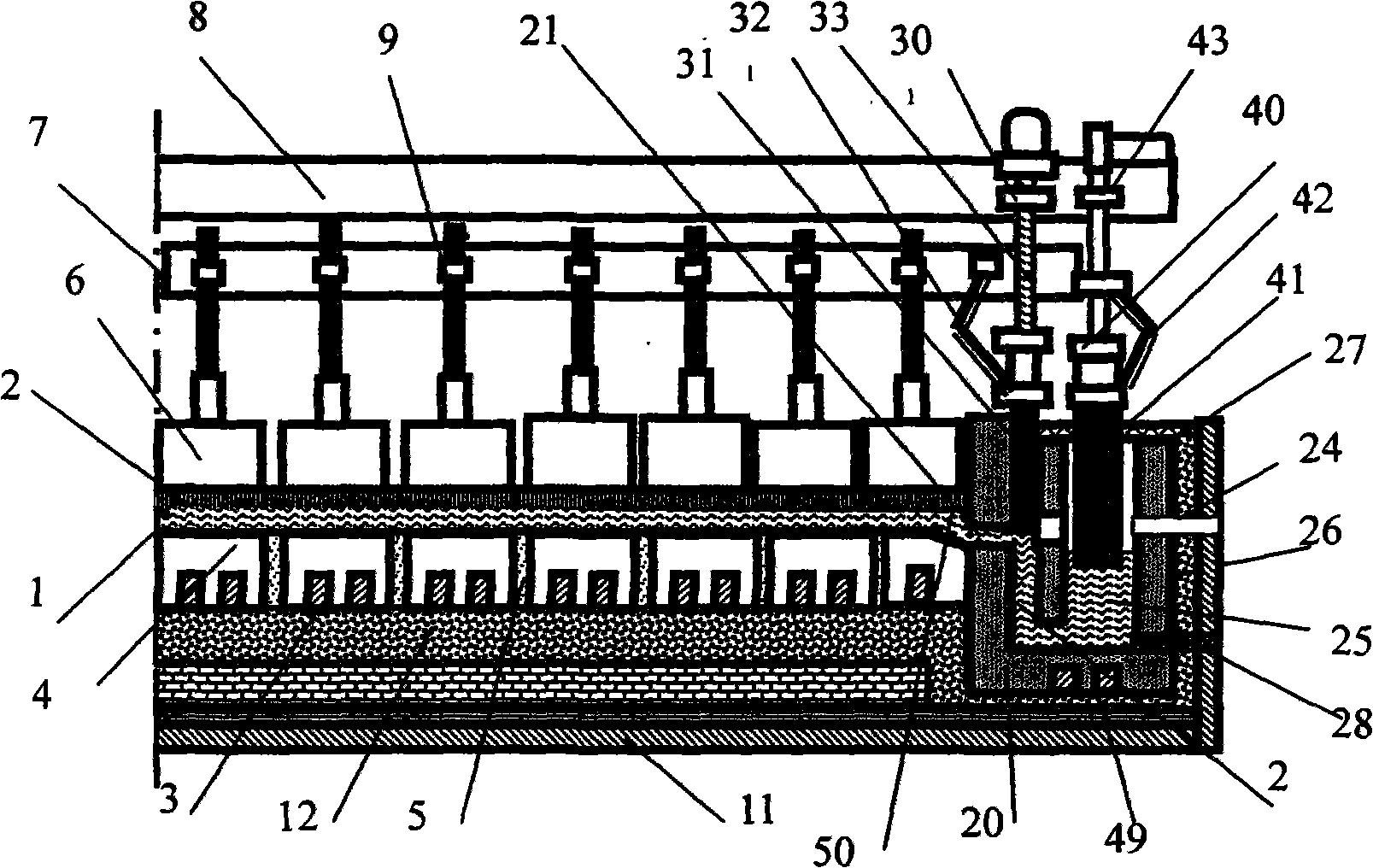

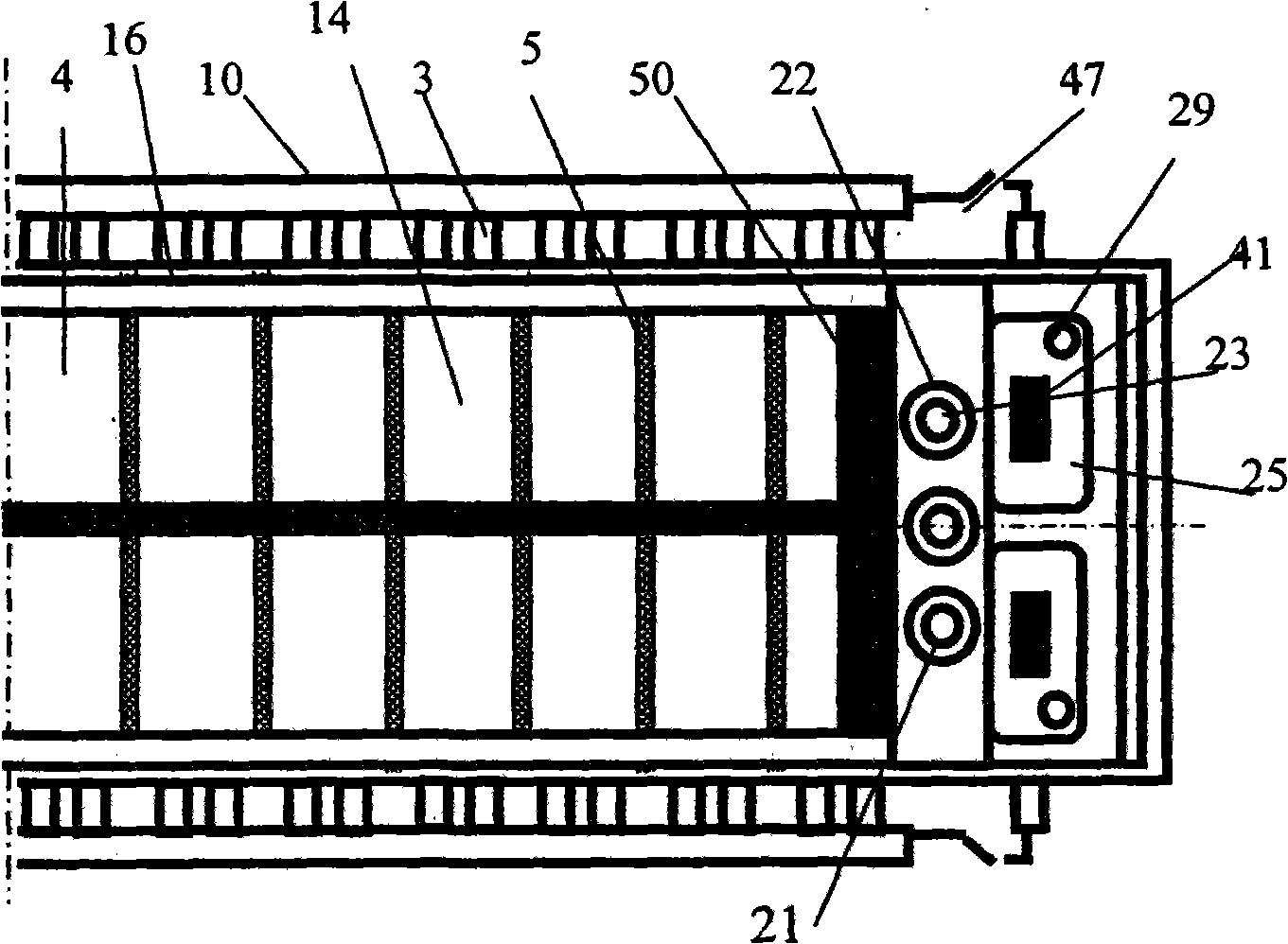

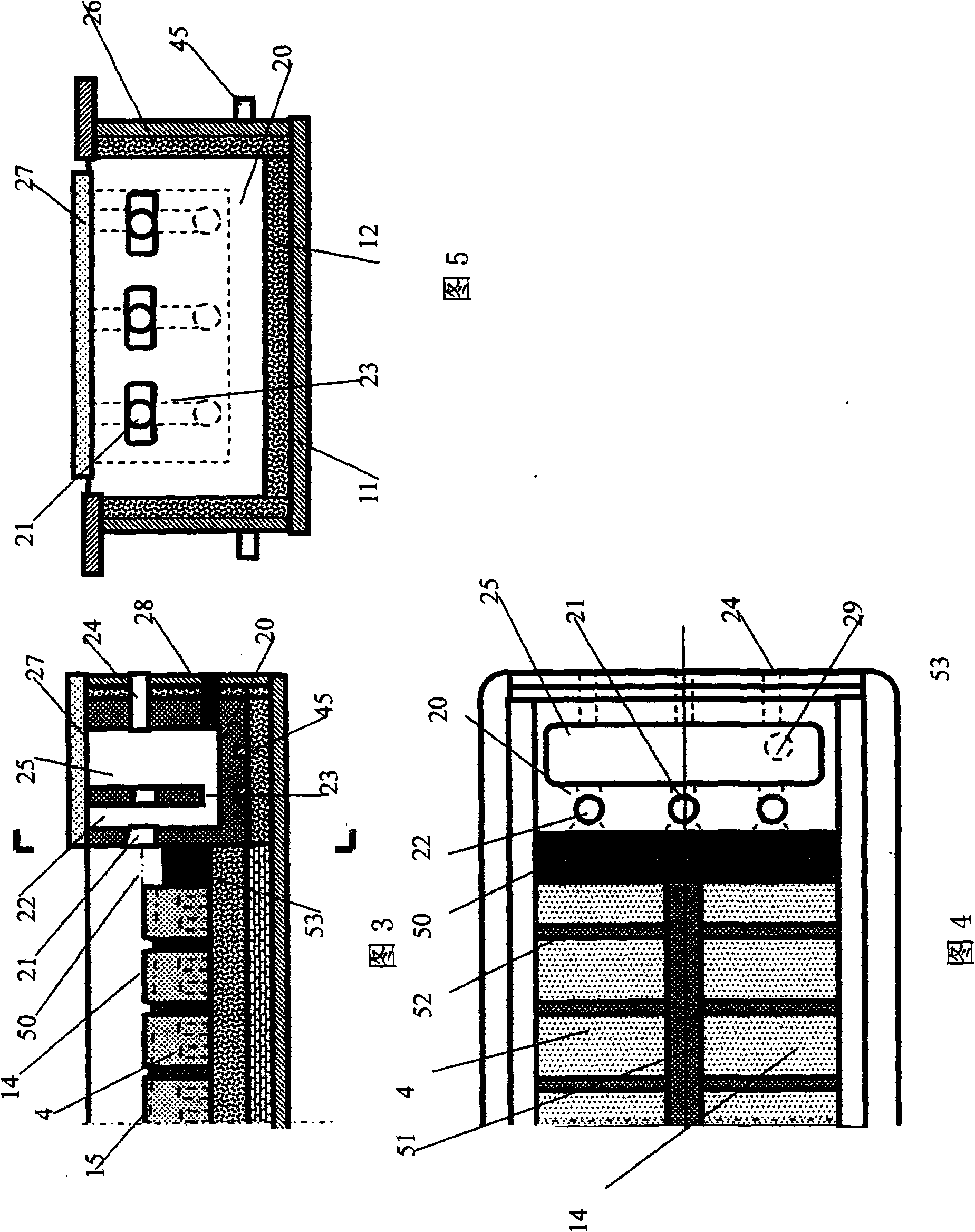

[0033] Implementation plan: A new type of aluminum electrolytic cell structure is innovatively designed on the basis of the current general aluminum electrolytic cell structure. The manufacturing and installation process of the structural components of the electrolytic cell can refer to the current relevant technical process standards. The main points of the masonry construction of a new type of aluminum electrolytic cell and the processing of parts are as follows:

[0034] 1. In the steel shell (11) of the electrolytic cell, according to the blueprint design and process requirements, build the insulation layer and the anti-leakage layer (12) of the cathode carbon block by masonry.

[0035]2. On the anti-leakage layer (12) in the steel shell (11) of the aluminum electrolytic cell, after determining the horizontal elevation and the position of the cathode carbon block (4) at the edge of the aluminum outlet, first construct and install the aluminum liquid storage The tank body (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com