Wind power plant with lightning protection arrangement

A technology for wind energy equipment and lightning protection, which is applied in wind energy generation, mechanical equipment, cable installation, etc., and can solve problems such as high cost and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

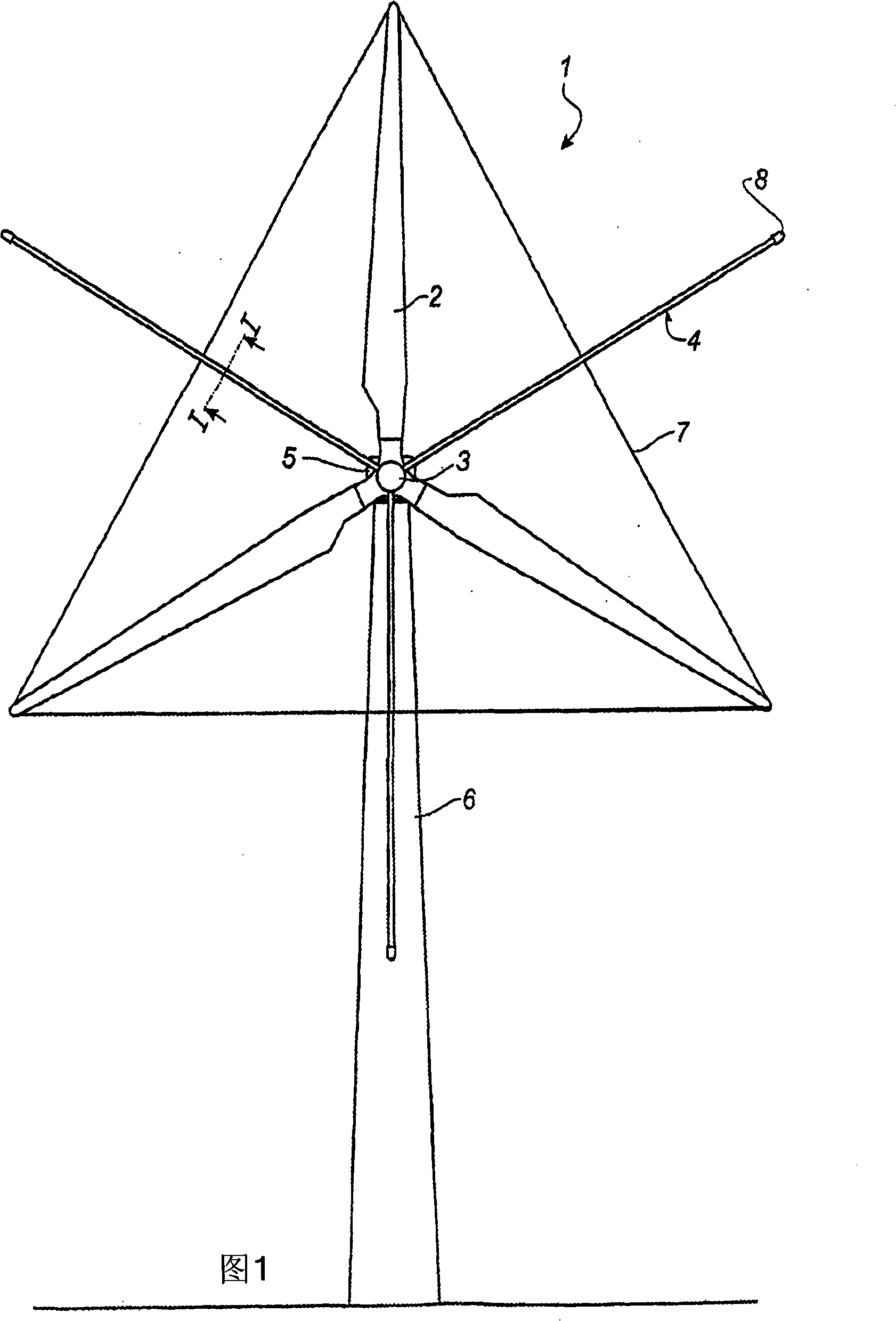

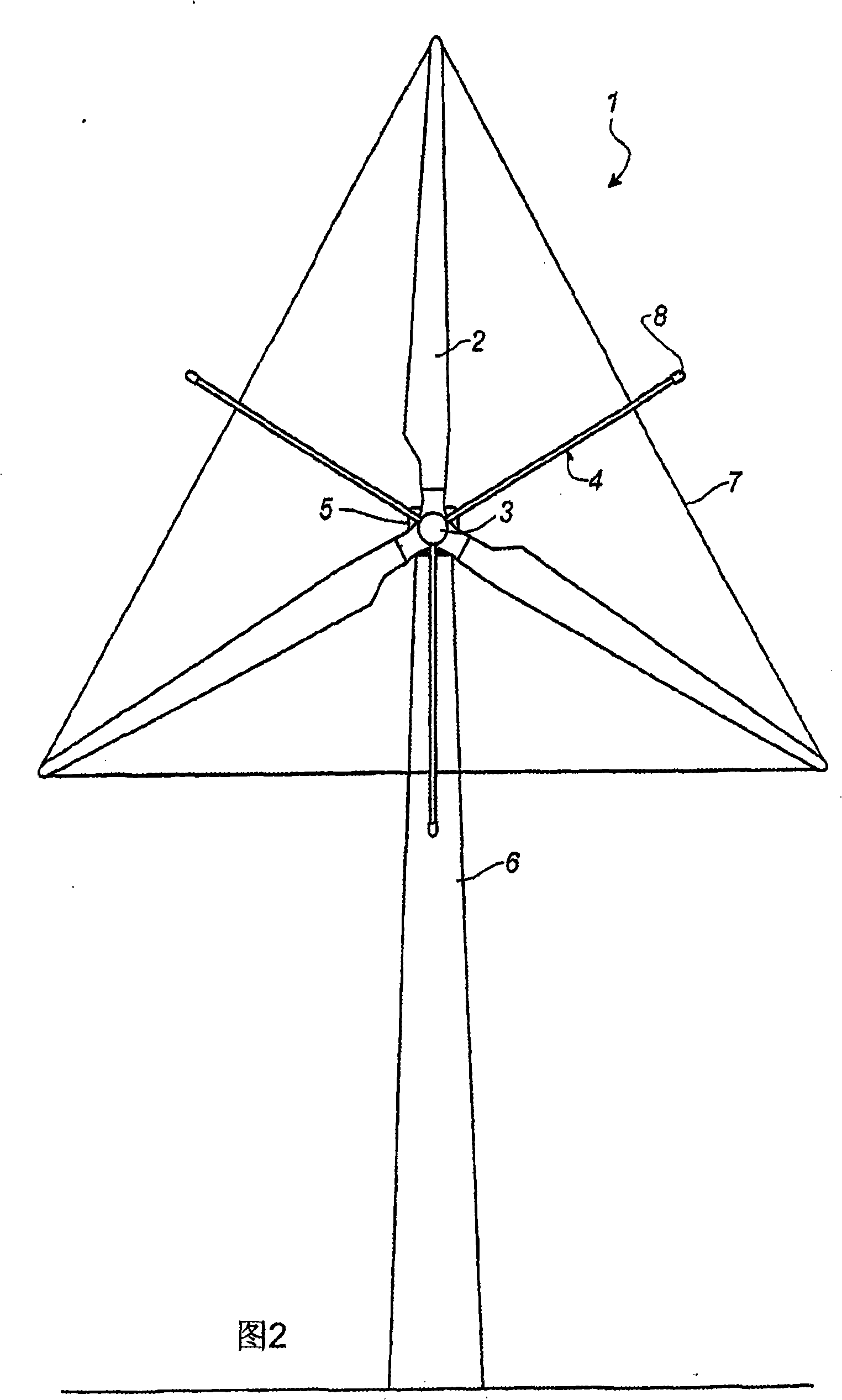

[0026] The wind power plant shown in FIG. 1 comprises a tower 6 supporting a nacelle 5 (also called windmill shell). A substantially horizontal main shaft projects outwardly from the nacelle 5 . A rotor is mounted on the shaft, and the rotor includes a hub 3 and a plurality of blades 2 . The rotor can be rotated by the wind. Preferably, the wind energy plant 1 is a so-called upwind plant, in which the wind hits the rotor before hitting the tower 6 , and in which the nacelle 5 can swing, that is to say rotate about a vertical axis relative to the tower 6 . The rotor thus adjusts itself to the direction of the wind at any given moment. Also, as shown in FIG. 2, the wind energy plant is preferably provided with three blades 2, which extend substantially radially outwards from the hub 3 and form a so-called shell made of polymeric material supplemented with glass fibers or carbon fibers production.

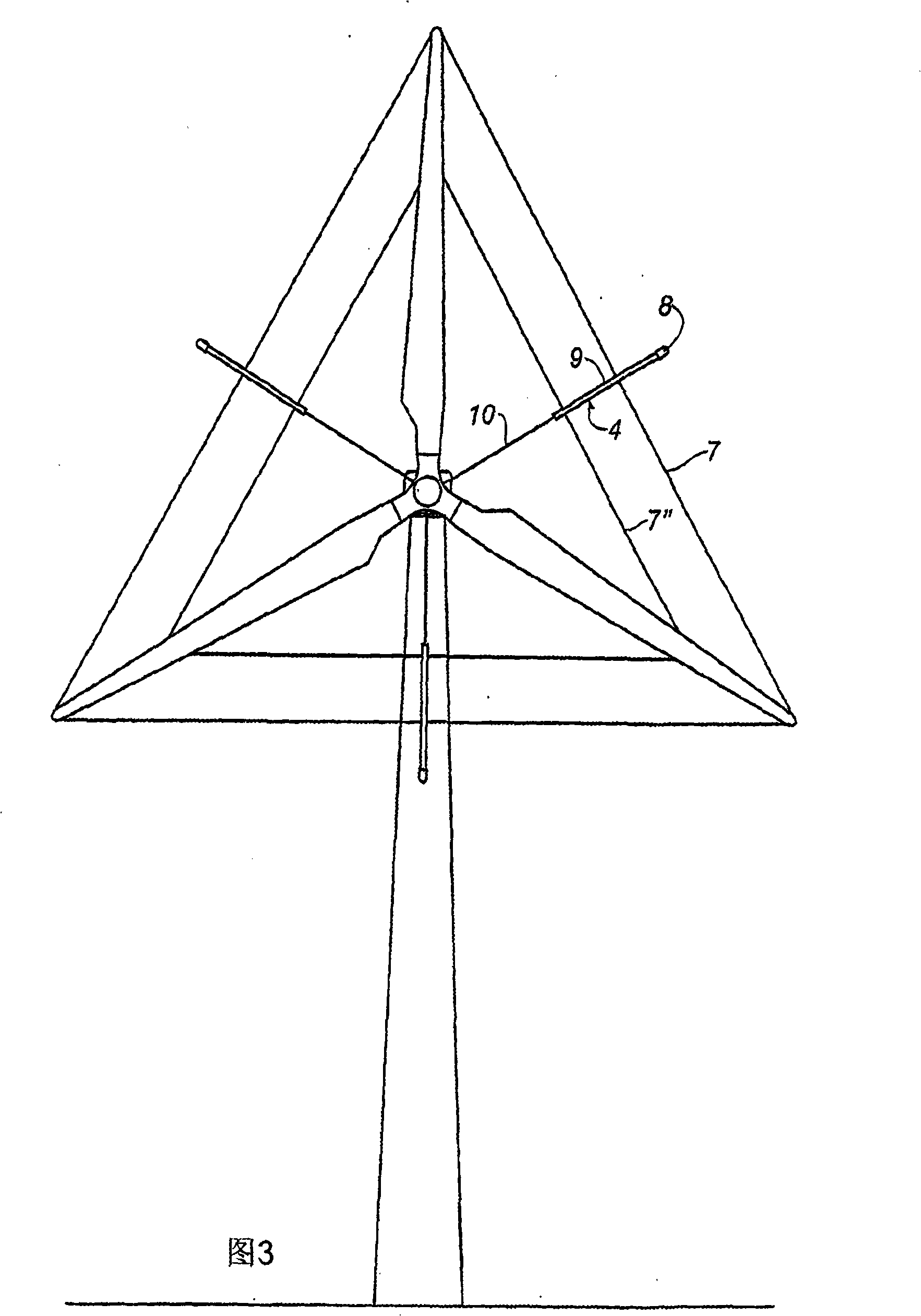

[0027] A typical feature of the wind energy plant 1 shown in FIG. 1 is that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com