Coupling method of shunting disk for thermal state furnace slag process

A diverter plate and slag technology, which is applied in the field of diverter plates for hot slag treatment, can solve the problems that the diverter plate cannot be positioned and connected, affects the service life of the diverter plate, and the workload of connection and disassembly is large, so as to prevent the inability to locate and connect , good force transmission function, and the effect of reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

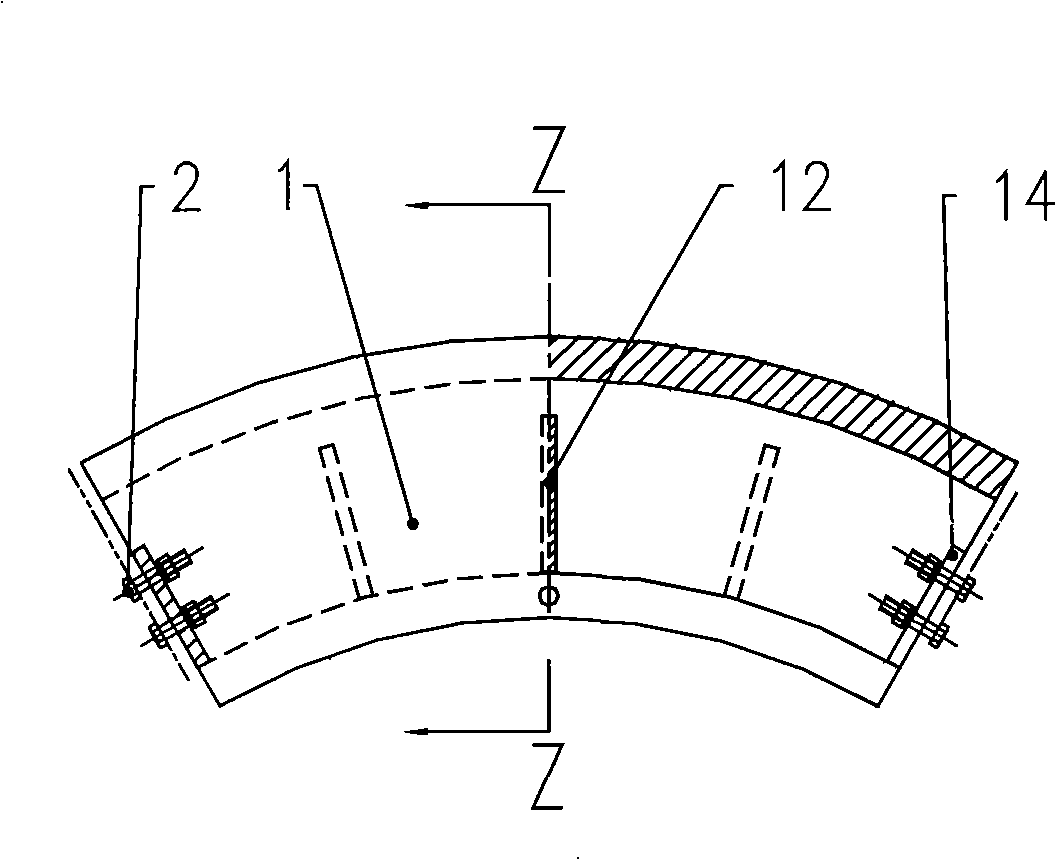

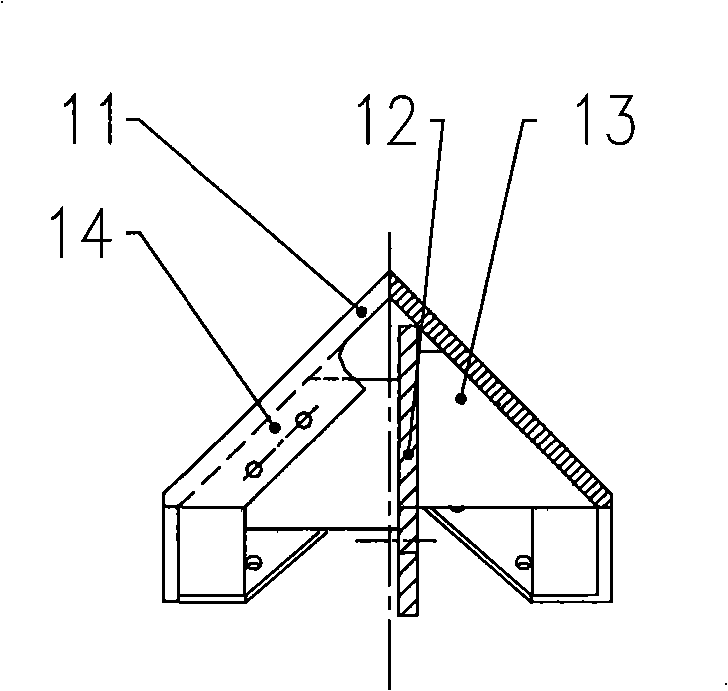

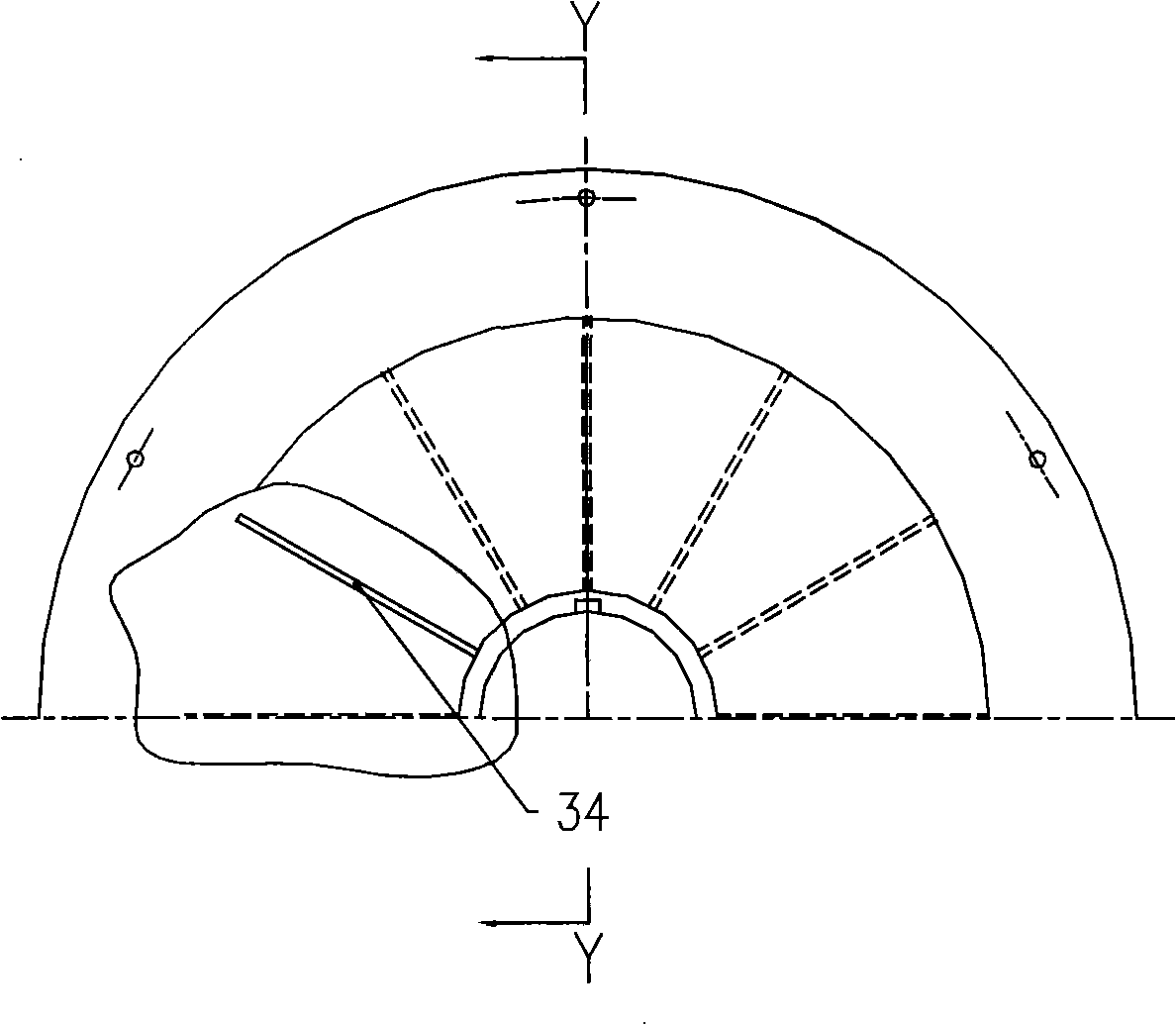

[0027] see Figure 7 , put the key 4 into the shaft 5, and then assemble the key 4 and the shaft 5 into the sleeve 33 of the diverter plate device 8 of the present invention, so that the key 4 and the keyway 35 are closely matched.

[0028] During operation, the external transmission mechanism drives the shaft 5 to rotate around its axis, and due to the transmission of the key 4, the diverter plate device 8 and the shaft 5 rotate together. Metallurgical slag 6 falls from the slag tank 7 onto the rotating splitter plate 8, touches the outer surface of its working plate 11, and flows outward along the outer surface of the working plate 11 by gravity and leaves the splitter plate device 8 .

[0029] Since the splitter tray device 8 is continuously impacted by the molten slag 6, the outer surface of the splitter tray device 8 has a heavy workload and poor environment. However, through the internal connection method of the present invention, each component is connected on the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com