Automobile luggage case link connection mechanism

A technology of trunk hinge and connecting mechanism, which is applied to hinges without pins, upper structure, vehicle parts, etc., can solve the problems of large cargo space and unsuitable for large trunk models, etc., achieve large space layout, and improve practical value , strengthen the fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

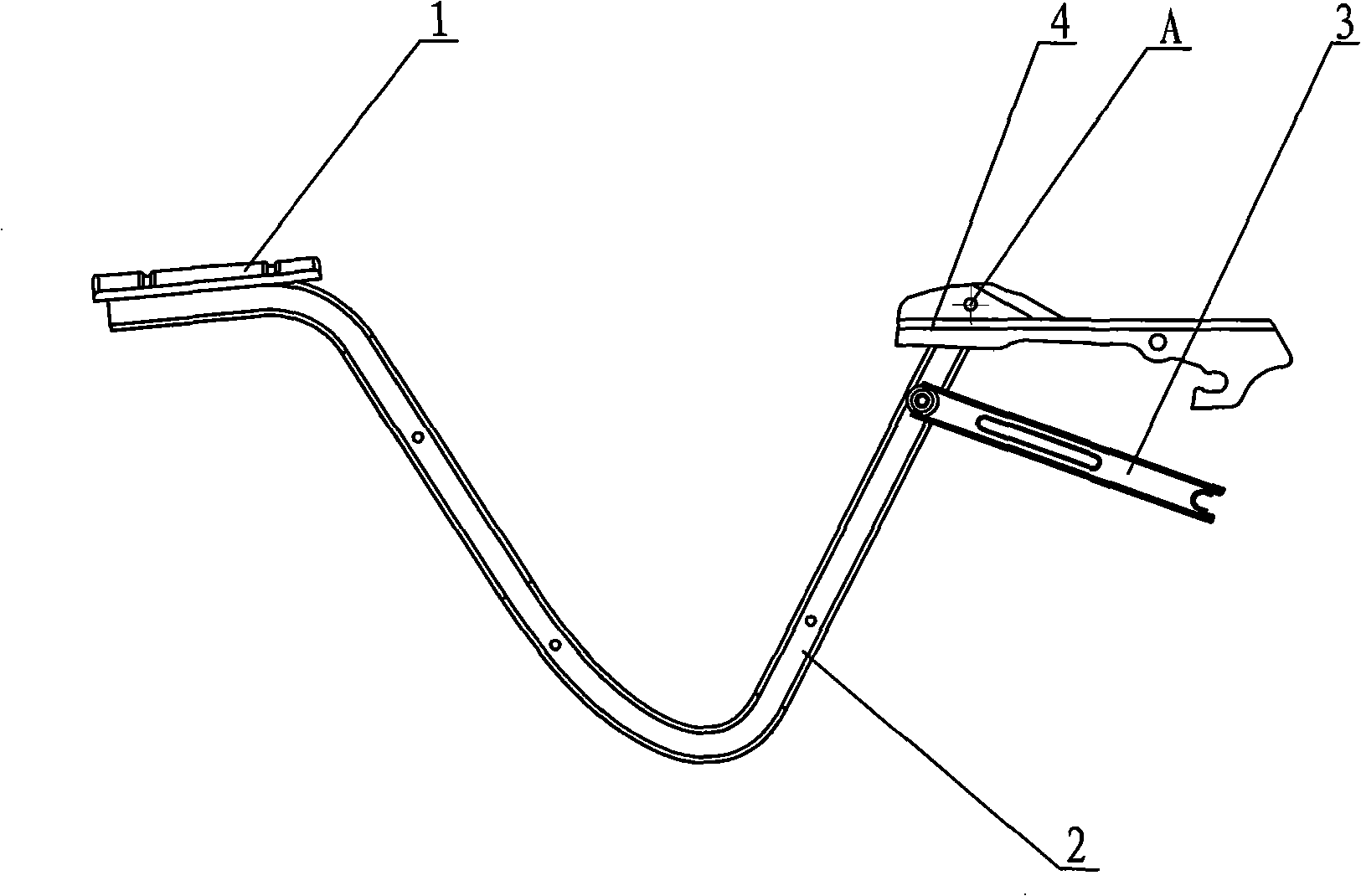

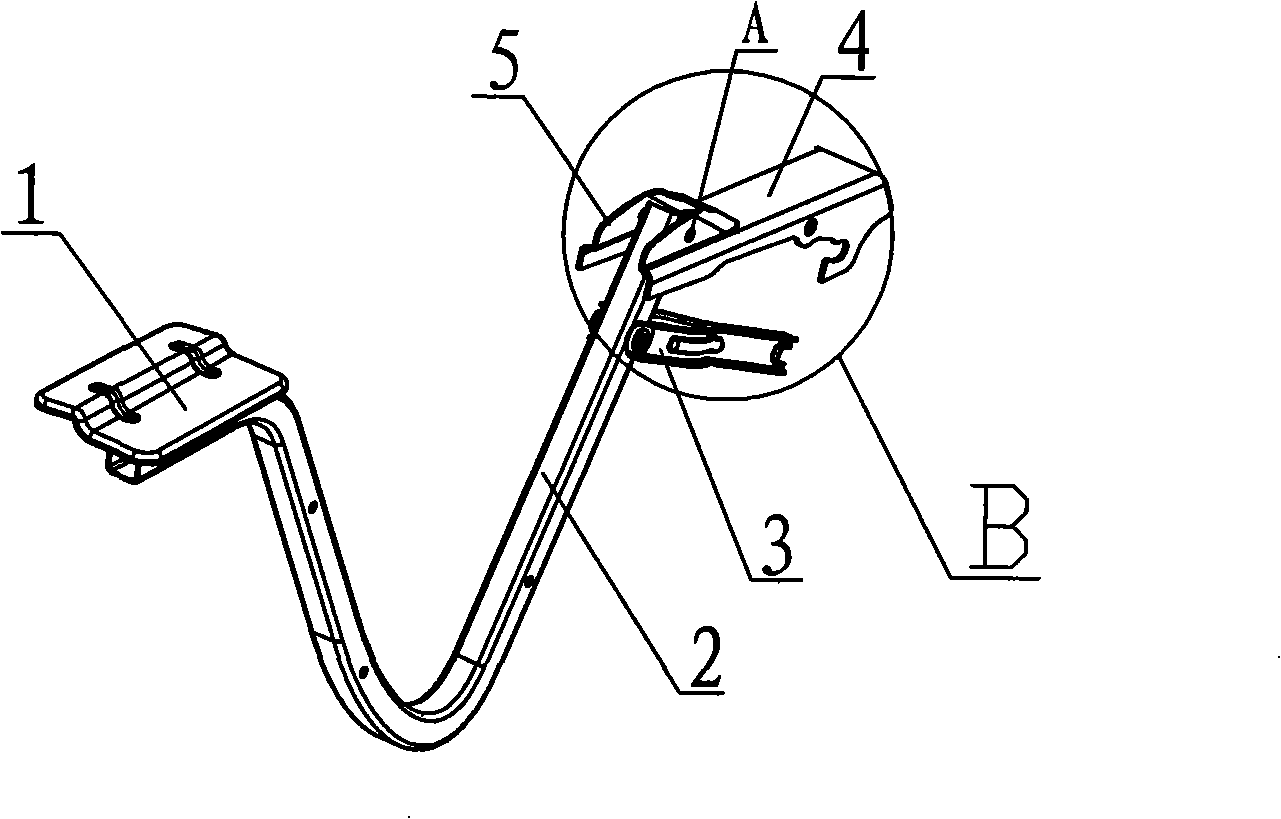

[0022] See figure 1 . According to the present invention: a hinged connection structure for a trunk of a car, comprising a trunk inner panel bracket 1, an elbow 2, an elbow connecting rod 3, and an elbow bracket 4, wherein one end of the elbow 2 extends horizontally, and the luggage is connected thereto. The box inner panel support 1, the other end is hinged with the end of the elbow bracket 4, and the elbow connecting rod 3 is hinged at the bottom. The optimal distance of the hinge point A of the support 4 is 790 mm, and the maximum angle of rotation of the elbow 2 around the hinge point A is 63 degrees.

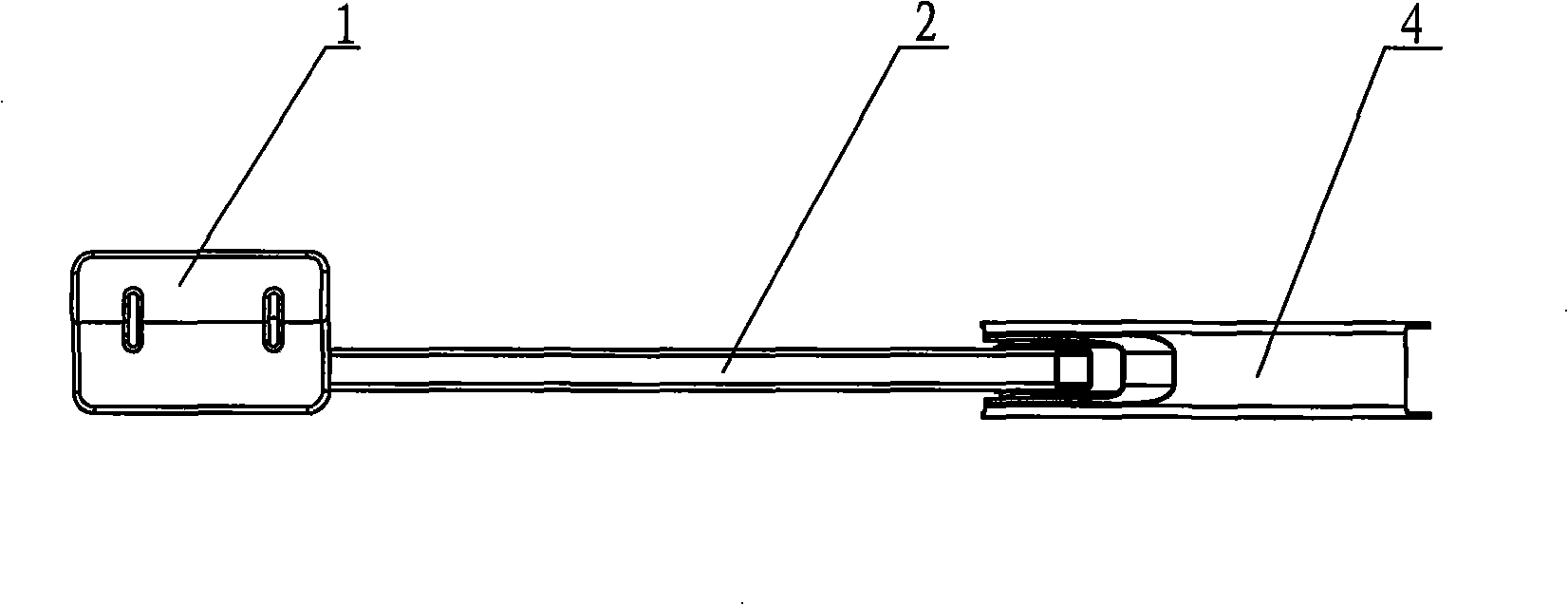

[0023] Such as figure 2 , image 3 , Figure 4 There is a "U"-shaped notch 5 at the joint between the bent pipe bracket 4 and the bent pipe 2 as shown, and the end of the bent pipe 2 is clamped in the "U"-shaped notch 5, and the "U"-shaped notch 5 faces into the trunk lid Opening in the direction of the board support.

[0024] The trunk inner panel support 1 shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com