Barrier sealing system for centrifugal compressors

一种压缩机、压缩机转子的技术,应用在发动机的密封、用于弹性流体的泵送装置的部件、液体变容式机械等方向,能够解决不能有效地防止油运移等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

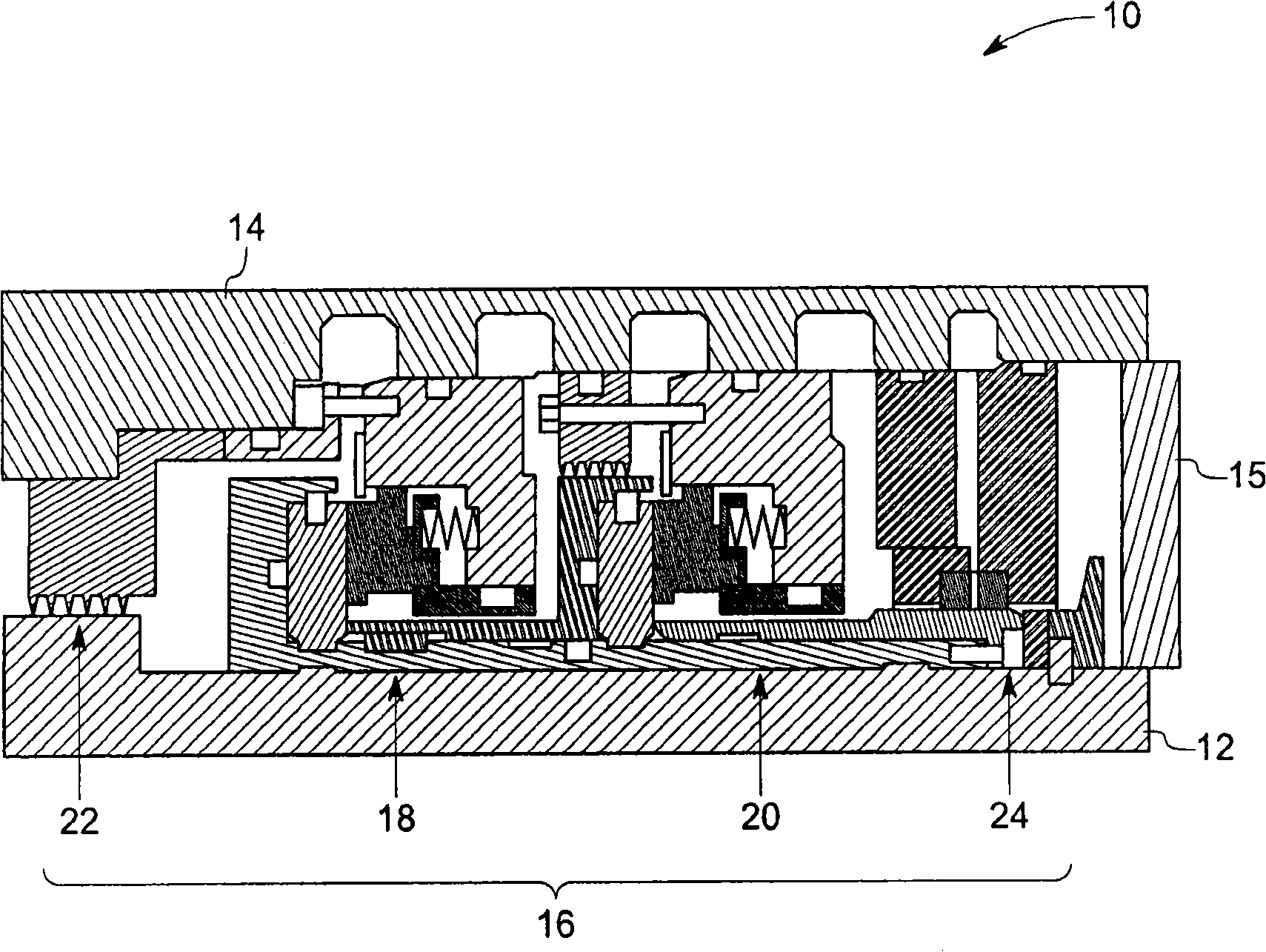

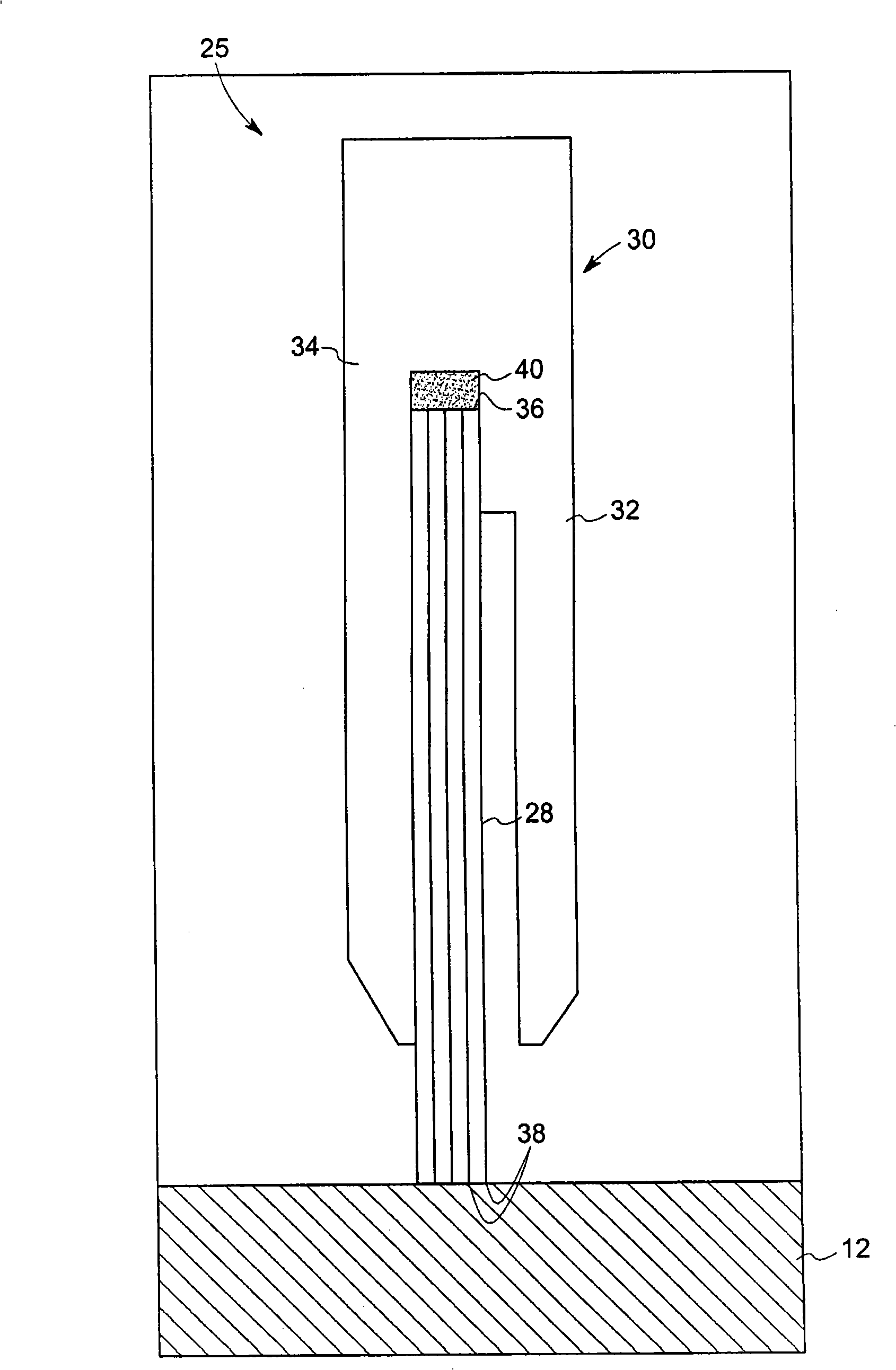

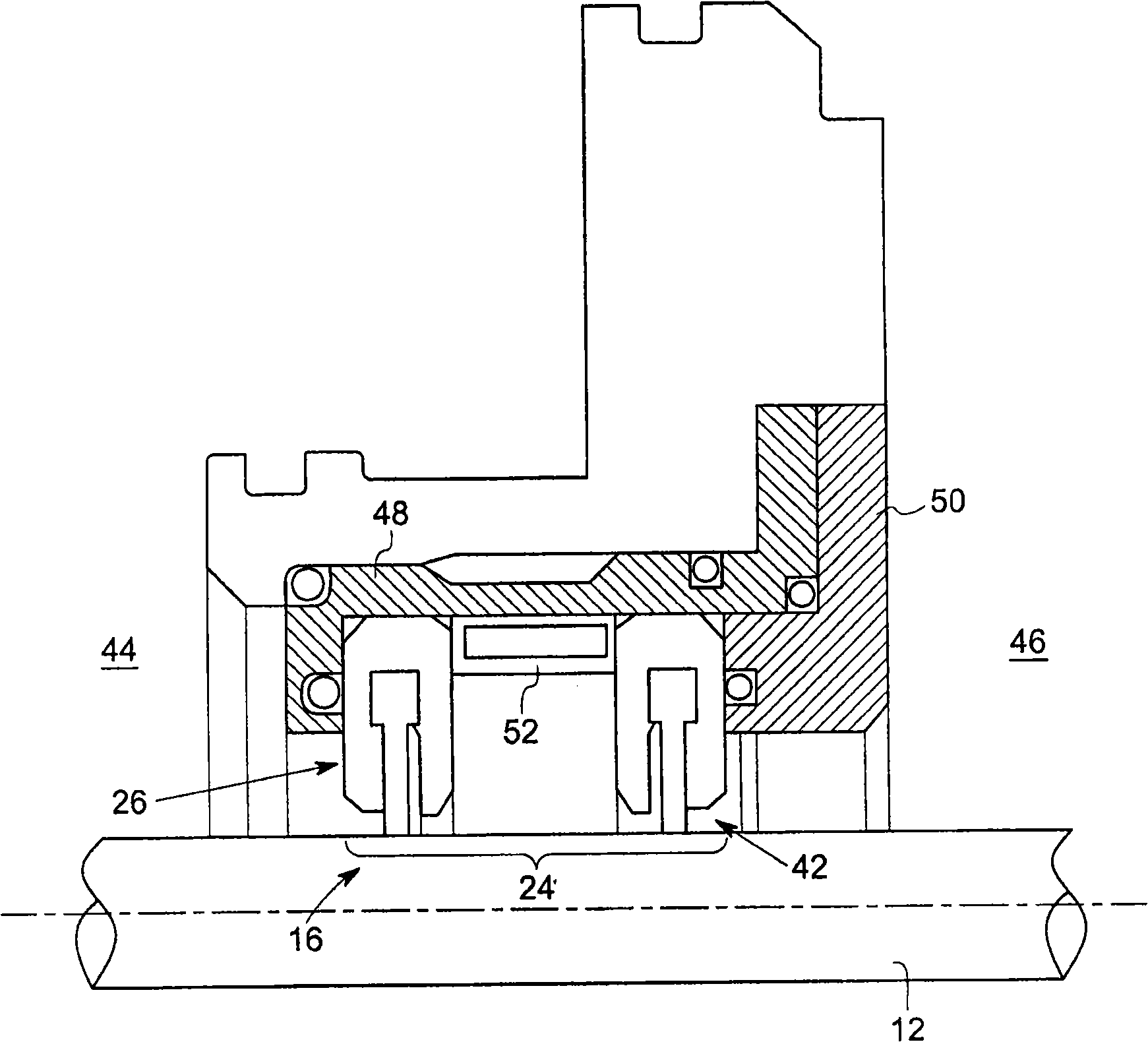

[0050] As discussed in detail hereinafter, embodiments of the present invention provide a rotating machine with a sealing arrangement disposed between a machine rotor and a machine stator. The sealing arrangement includes a dry gas seal, a first seal disposed on a first side between the dry gas seal and the bearing and a first seal disposed on a second side between the first seal and the bearing to provide a rotor of the machine. Two seals. In some exemplary embodiments, the first seal comprises a brush seal comprising non-metallic fibers. In some exemplary embodiments, the second seal includes a brush seal. In some exemplary embodiments, the first seal and the second seal may include brush seals each including a plurality of non-metallic fibers. Both the first seal and the second seal are configured to prevent oil leakage towards the dry gas seal. In some embodiments, other seals such as labyrinth seals or carbon face seals are used in conjunction with the first and second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com