Device for compacting sand soil foundation by librating

A sandy soil foundation and vibratory compaction technology, which is applied in the fields of soil protection, transportation and packaging, and infrastructure engineering, etc., can solve the problem of high construction costs and achieve the effect of increasing the compacted area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

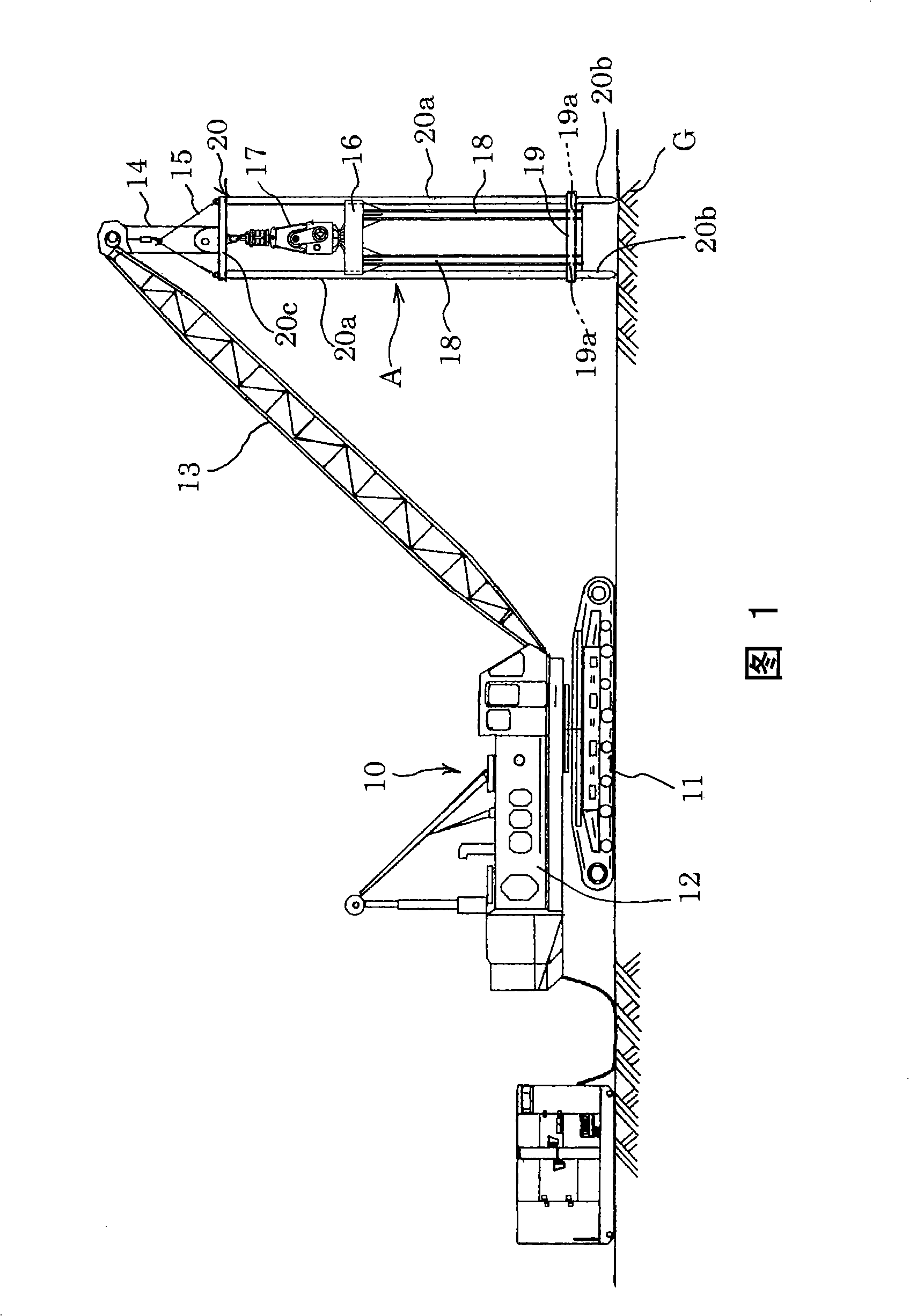

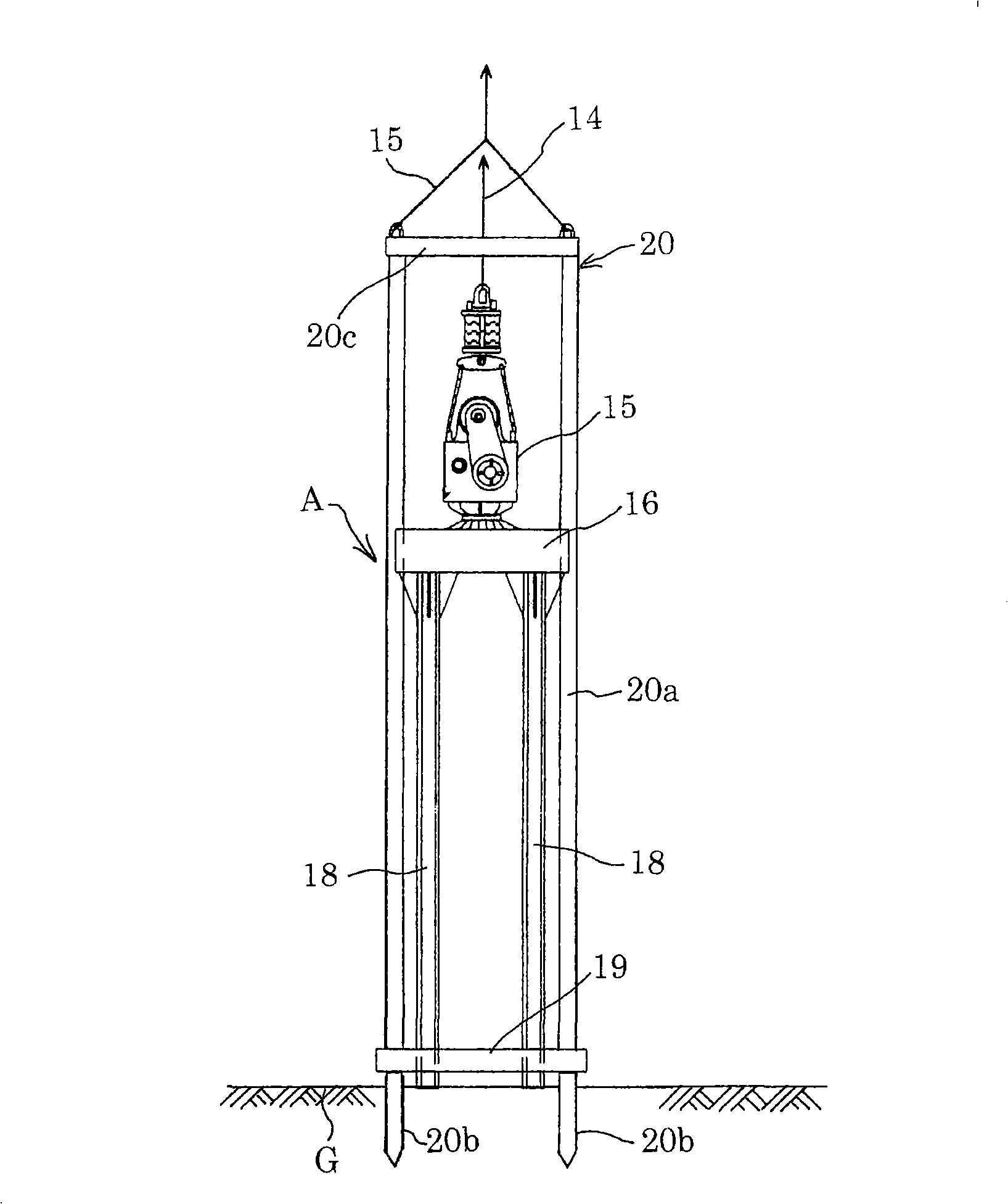

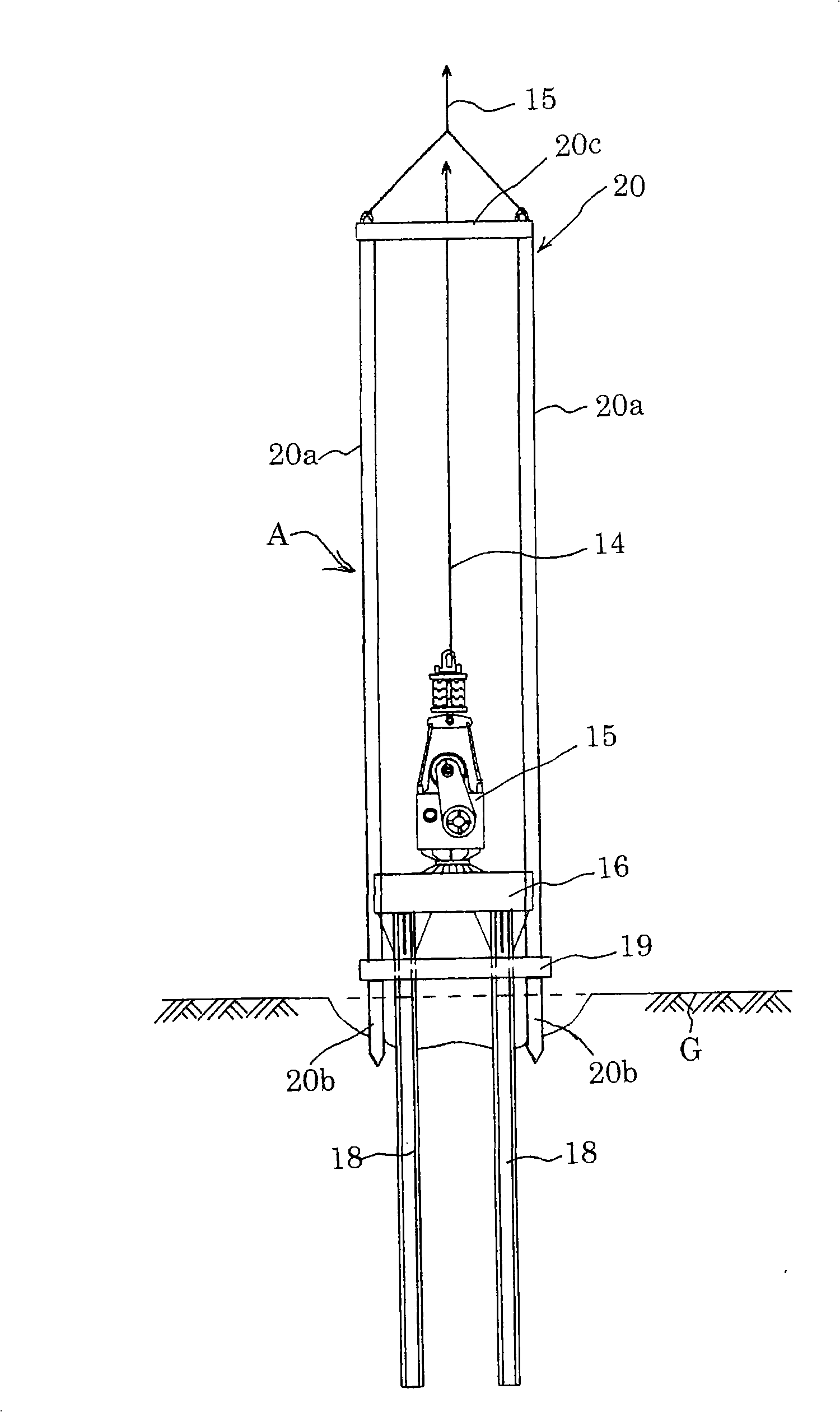

[0050] The present invention will be specifically described below according to the embodiments shown in the accompanying drawings.

[0051] In order to achieve the purpose of making the reinforcement range of the sandy soil foundation as wide as possible by the rod pressing construction method, and processing it at the same time, reducing repeated operations of small-space construction, and reducing construction costs, a rod compacting device is provided , which is characterized in that the device is basically box-shaped, including a rod installation arm, a plurality of rods are vertically fixed at a certain distance from each other on the bottom surface of the rod installation arm, and fixed at the center of the top surface of the rod installation arm. There is a vibratory hammer. In addition, the vibratory hammer is connected to the main winding wire rope of the crawler crane, and a box-shaped metal holder is provided. The metal holder can move up and down simultaneously acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com