Carriage-mounted unit of weft knitting machine

A technology of tripod carriage and flat knitting machine, which is applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems that the miniaturization and light weight of tripod carriage cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the drawings.

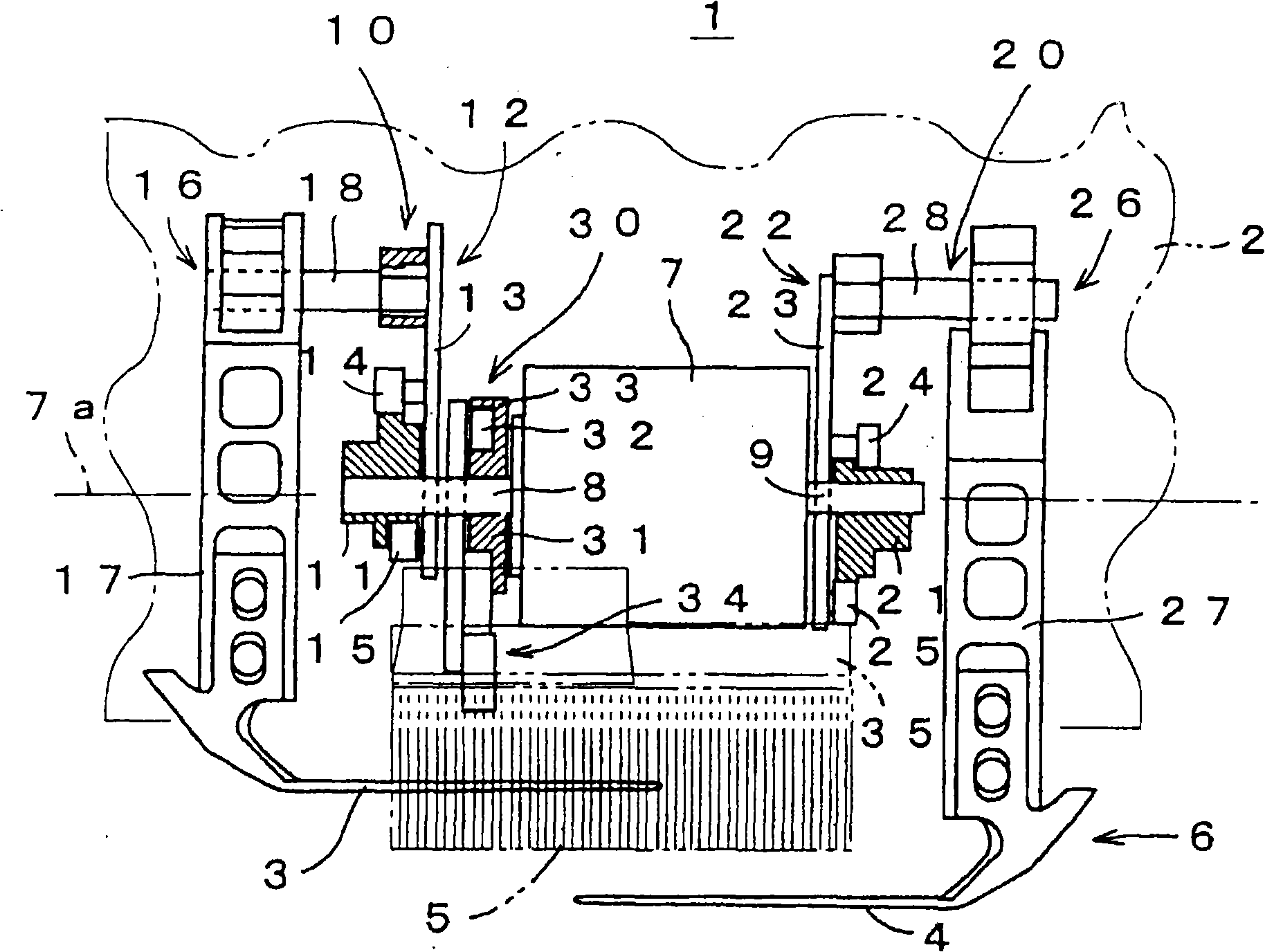

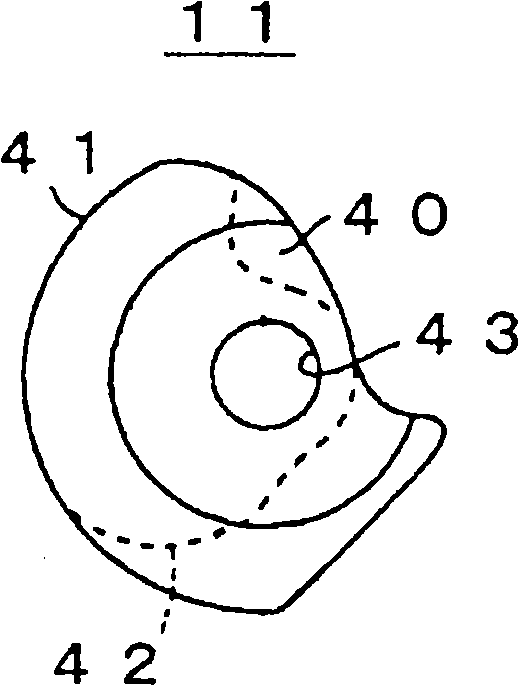

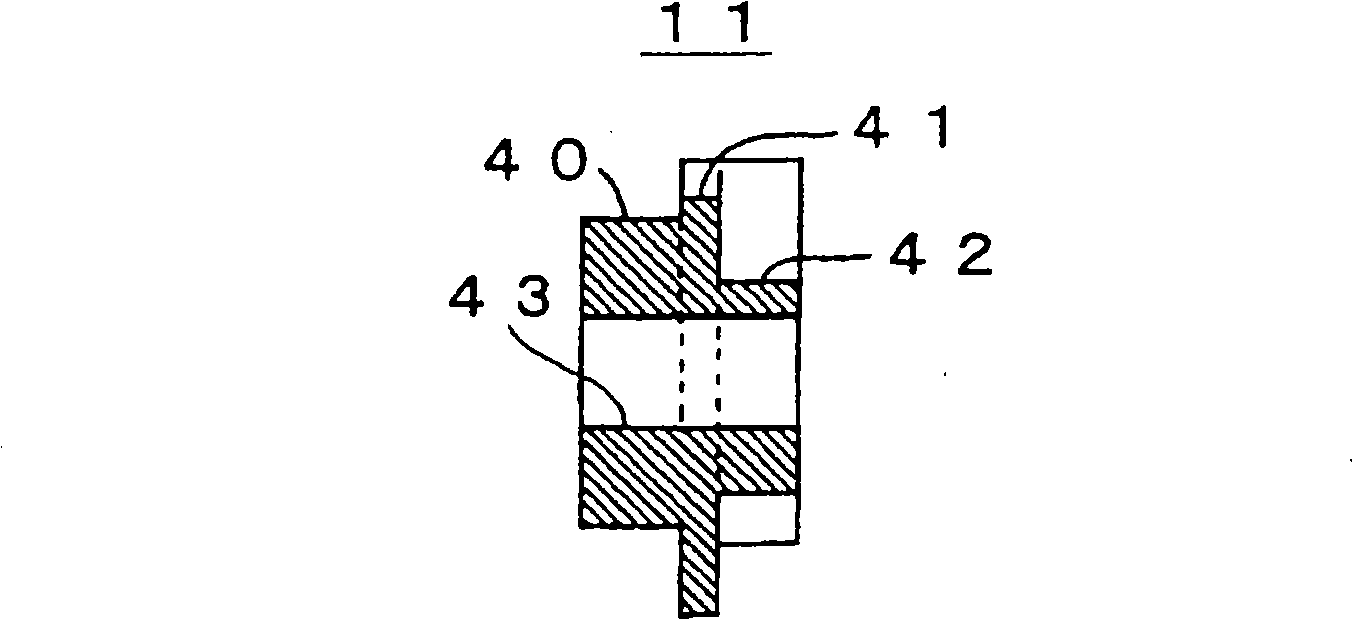

[0030] figure 1 The schematic structure of the drive unit 1 as an embodiment of the present invention is shown. The drive unit 1 is mounted on a carriage 2 that reciprocates along the needle bed of the flat knitting machine, and functions as a carriage mounting unit of the flat knitting machine. The carriage 2 performs selective driving for knitting the knitted fabric by retreating the knitting needles from the needle bed. The drive unit 1 includes a pair of components that can be switched according to the moving direction of the carriage 2 and has at least three components that can advance and retract independently of the knitting needles. That is, a pair of pressure needle plates 3, 4, that is, one needle pressure plate 3 and the other needle pressure plate 4 can be switched between each other according to the movement of the carriage 2 in the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com