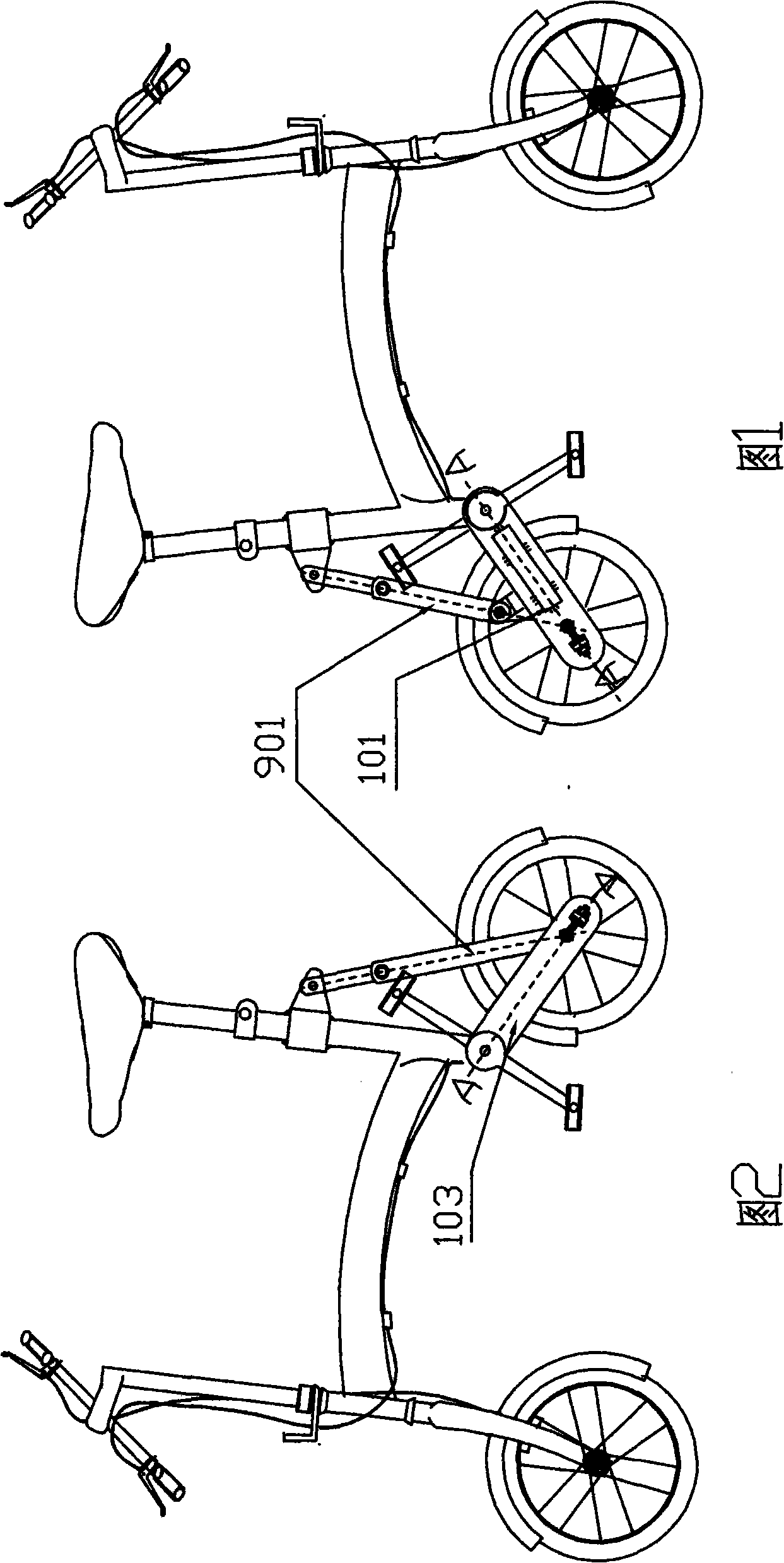

Transmission bicycle by resistance power of toothed chain

A power transmission, bicycle technology, applied in vehicle components, rider drive, transportation and packaging, etc., can solve the problems of long actual pitch, poor meshing, asymmetrical non-elliptical half chain cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

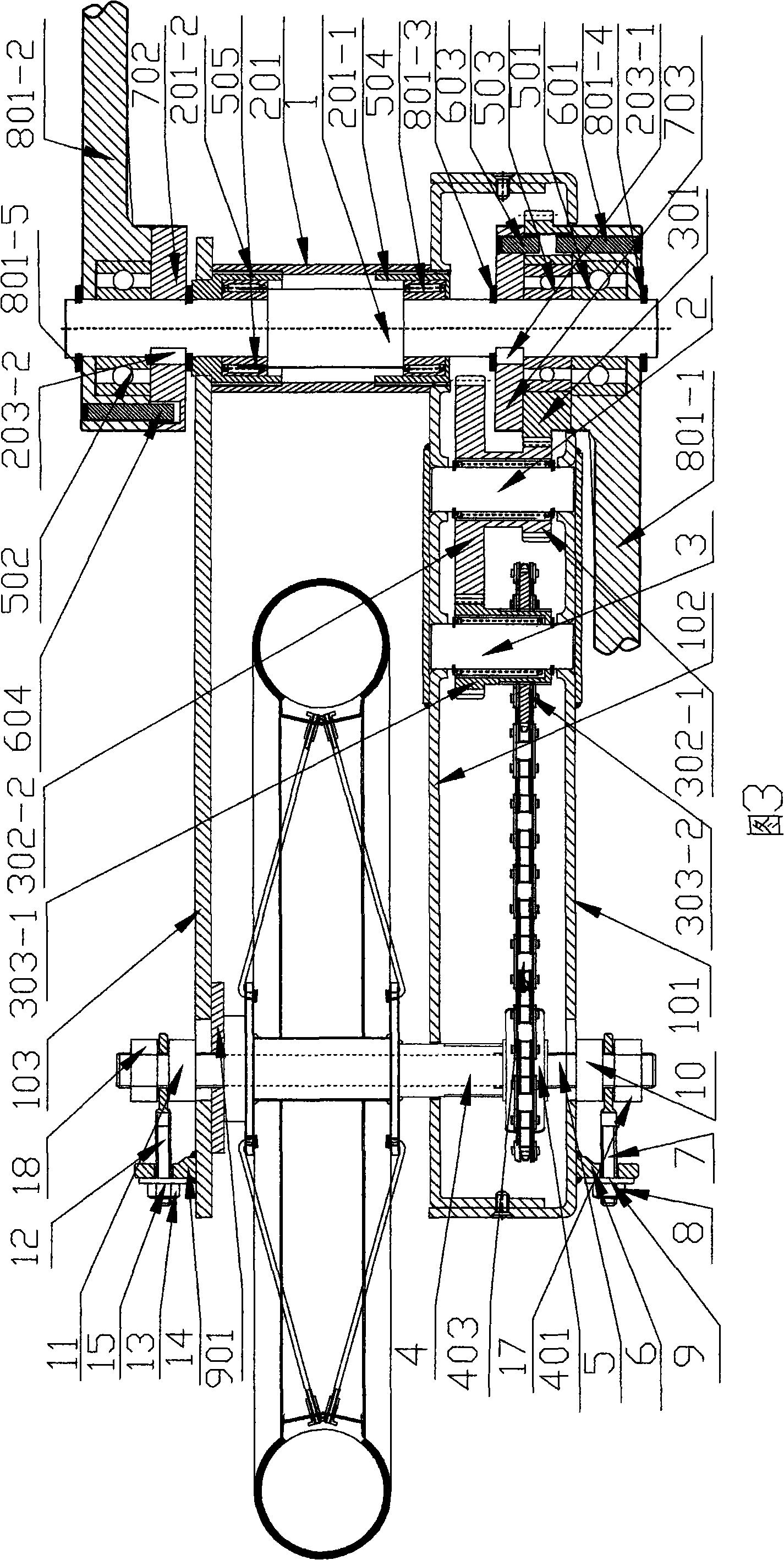

Embodiment Construction

[0022] Concrete structure of the present invention please refer to accompanying drawing. First put the bearing (504) in the right central axis bowl (201-1), and screw it on the right end of the central tube (201), and screw the inner plate (102) on the right central axis bowl (201-1) Put the right end of the central shaft (1) through the central shaft hole on the right central shaft bowl (201-1), install the retaining ring (801-3), and weld the left fork plate to the inner sleeve bearing (505 ) on the left central axis bowl (201-2), then pass the left central axis bowl (201-2) fixed with the left fork plate through the left end of the central axis (1) and screw on the left end of the central tube (201) , install the dual gears (302-1) and (302-2) with bearings on the II shaft (2), and install retaining rings at both ends, and install the II shaft (2) with the dual gears One end of the inner plate is installed on the corresponding shaft hole of the inner plate, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com