Paper ship production method

A production method and technology of paper boats, applied to boats, toys, instruments, etc., can solve the problems of destroying the firmness of paper, causing wrinkles, and damaging paper boats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

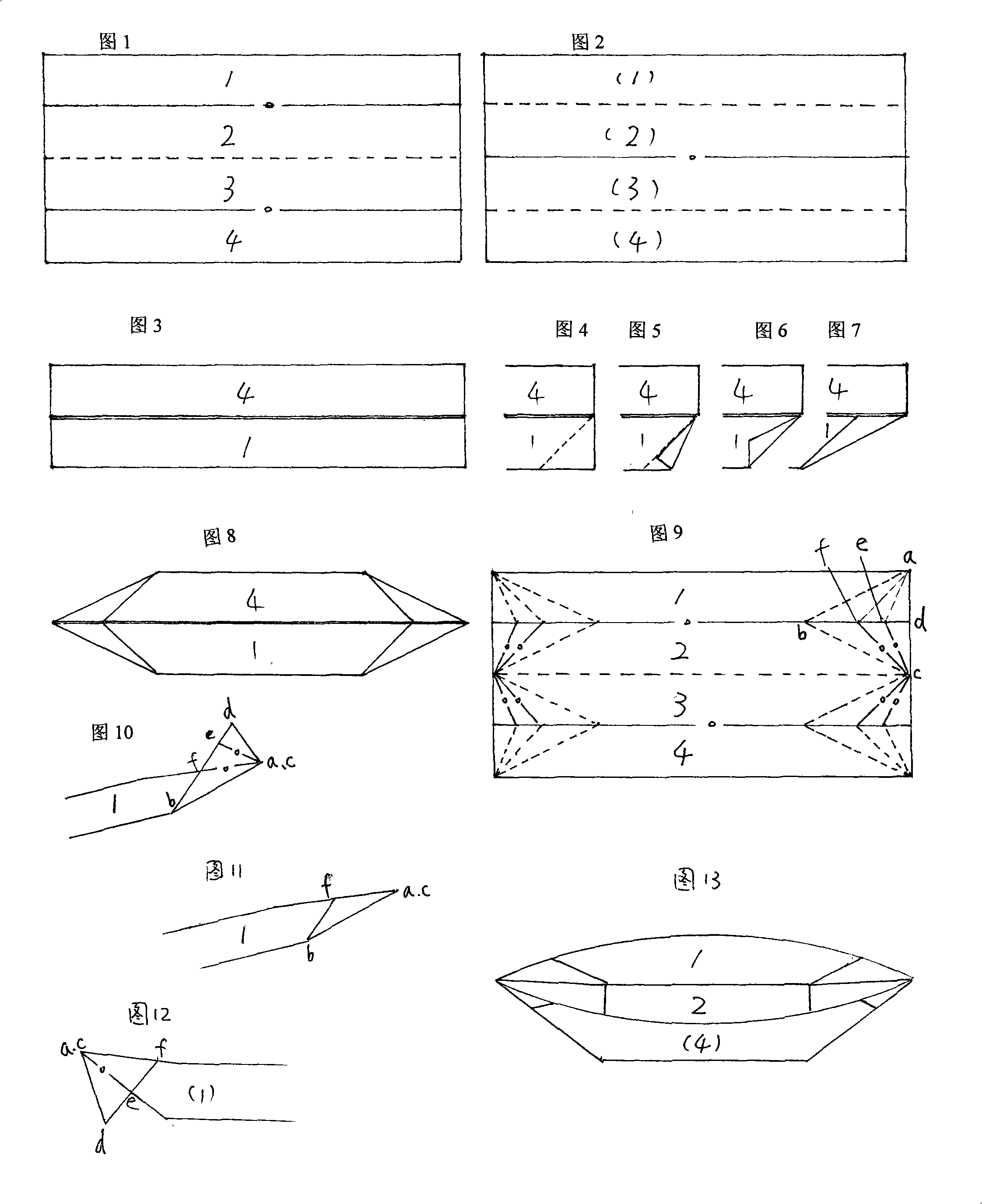

[0019] Further explanation will be made in conjunction with accompanying drawings.

[0020] Fold a rectangular paper with a length and width of about 2:1 and fold it into four equal parts (as shown in Figure 1). Between 1 and 2 and between 3 and 4 are reverse creases, and between 2 and 3 are regular folds Creases; the reverse side is shown in Figure 2; fold 1, 2, 3, 4 to form Figure 3, and the edges of 1 and 4 are connected to the center line; fold the lower right corner forward to form a 45-degree crease, as shown in Figure 4; Based on the 45-degree crease line, fold the lower right corner forward at 22.5 degrees, as shown in Figure 5; fold the crease line at the 45-degree angle, as shown in Figure 6; fold the folded part forward at 22.5 degrees, as shown in Figure 7; fold the other three corners Fold into this shape, as shown in Figure 8; unfold the paper completely, as shown in Figure 9; use the upper right corner of Figure 9 for further explanation, the crease between 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com