Integral type garden tool handle

A garden tool and integrated technology, applied in the field of integrated garden tool handles, can solve the problems of unsatisfactory product stability and difficult processing of the connecting end of the tool handle, so as to improve the operation efficiency, reduce the operation difficulty and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

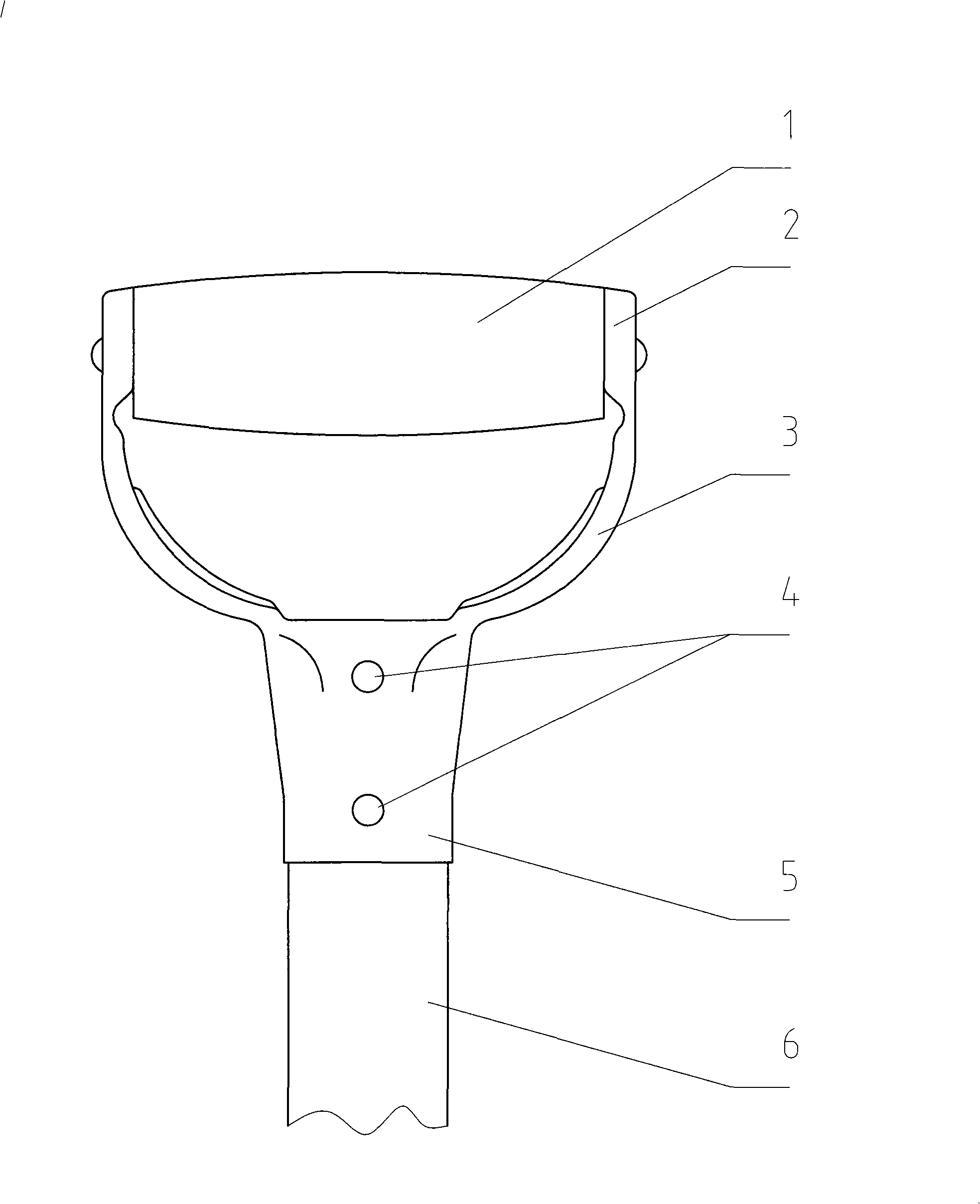

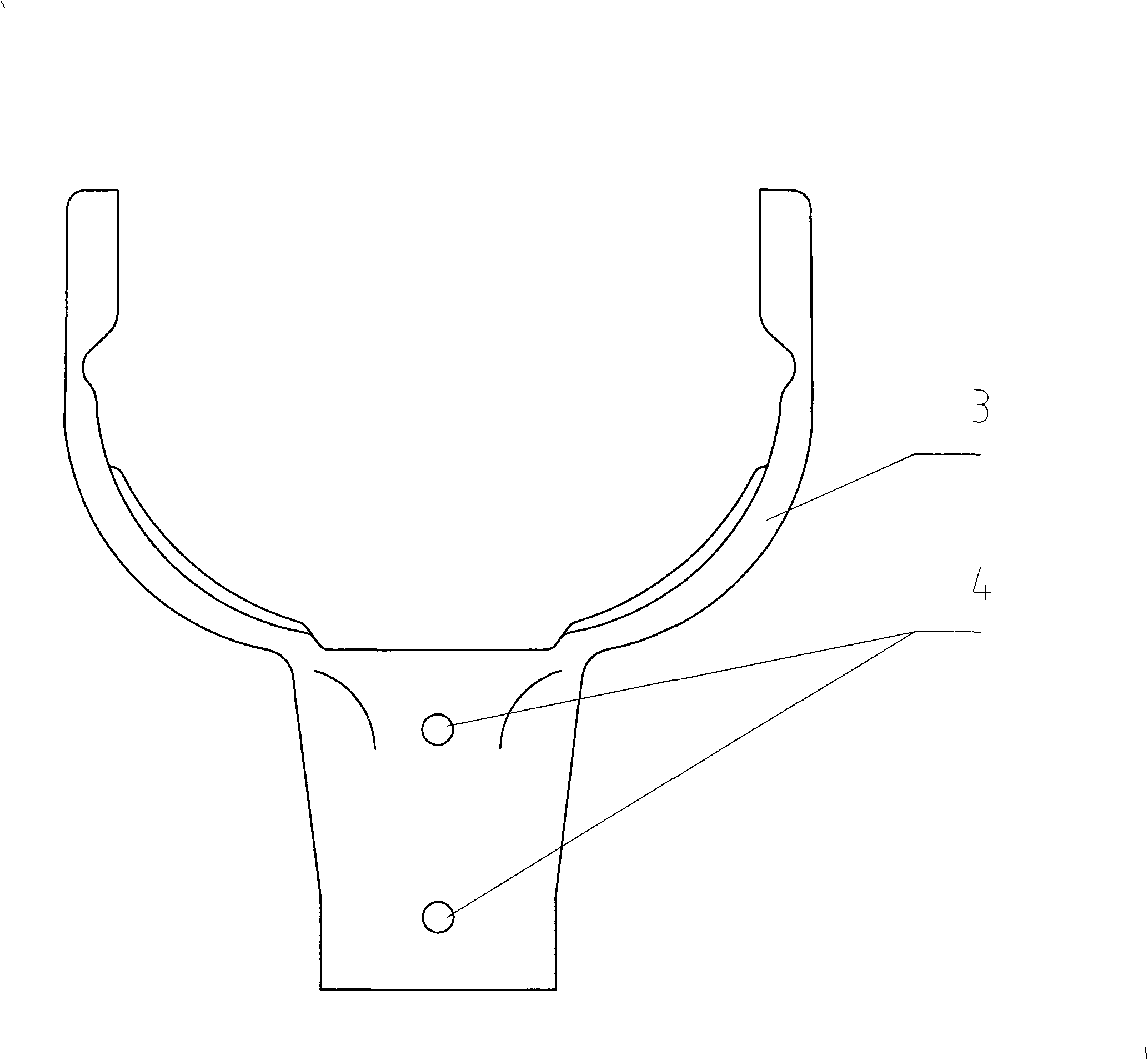

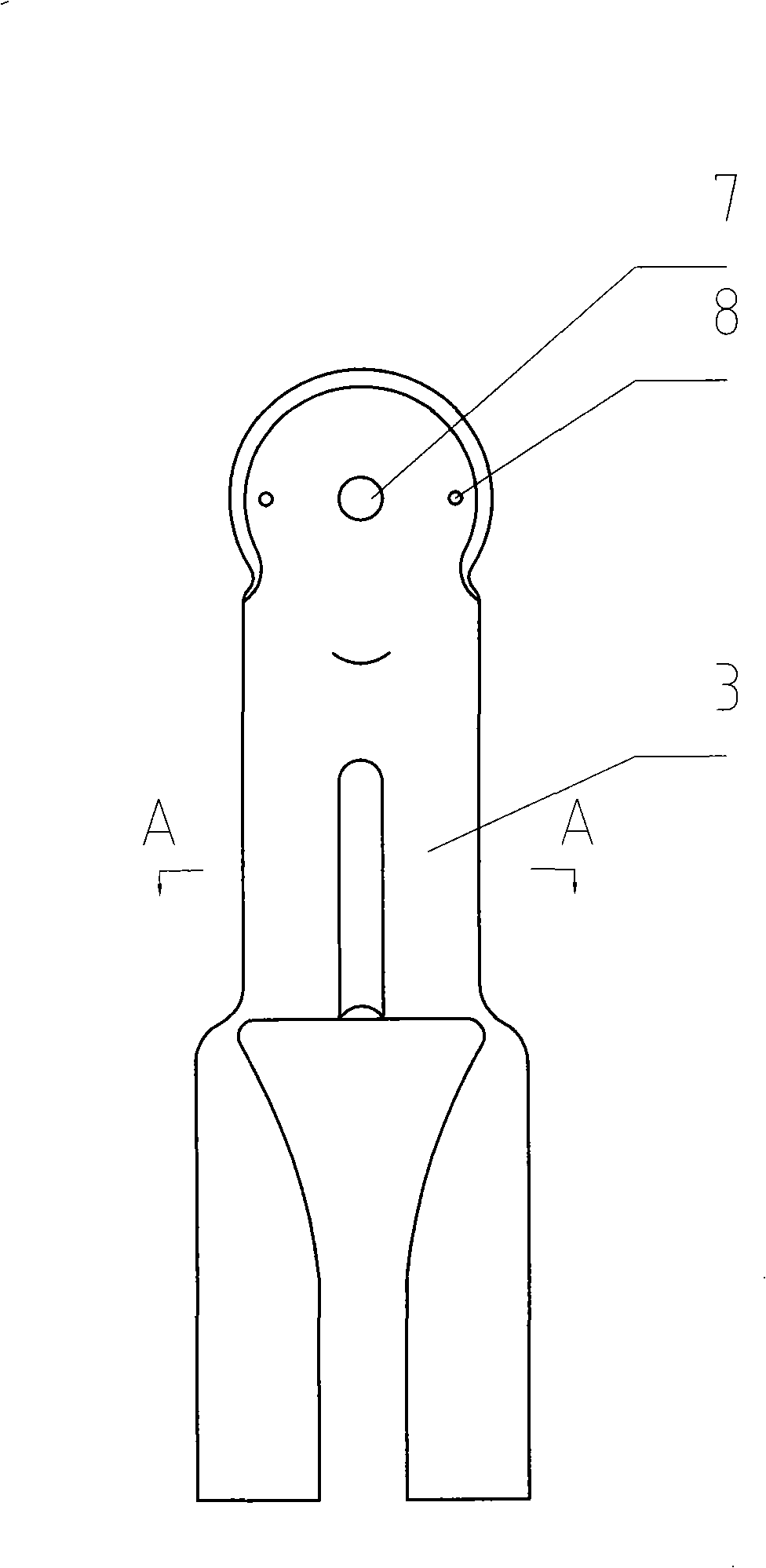

[0011] See figure 1 , figure 2 , image 3 , Figure 4 , a handle of an integral garden tool, including a handshake 1, the handle body is composed of an upper support body 3 fixed to the handshake 2 and a lower connecting body 5 fixed to the tool handle, and the support body 3 is provided with a protrusion The reinforcing rib 9, the handshake connection hole 7 and the positioning hole 8, the connecting body 5 is composed of two arc surfaces smaller than a semicircle, and the two arc surfaces and the support body 3 are a stamped integral connection structure, and the There are connecting holes 4.

[0012] See figure 1 , figure 2 , image 3 , Figure 4 , the connection method of the present invention is: the overall cross-section of the handle is designed as an unclosed shape, and a circular arc-shaped reinforcing rib 9 is arranged in the middle part of the weak force to increase its strength. When assembling the tool handle, when assembling the tool handle, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com