Drop dies with movable bush fitting

A technology of movable inserts and forging dies, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

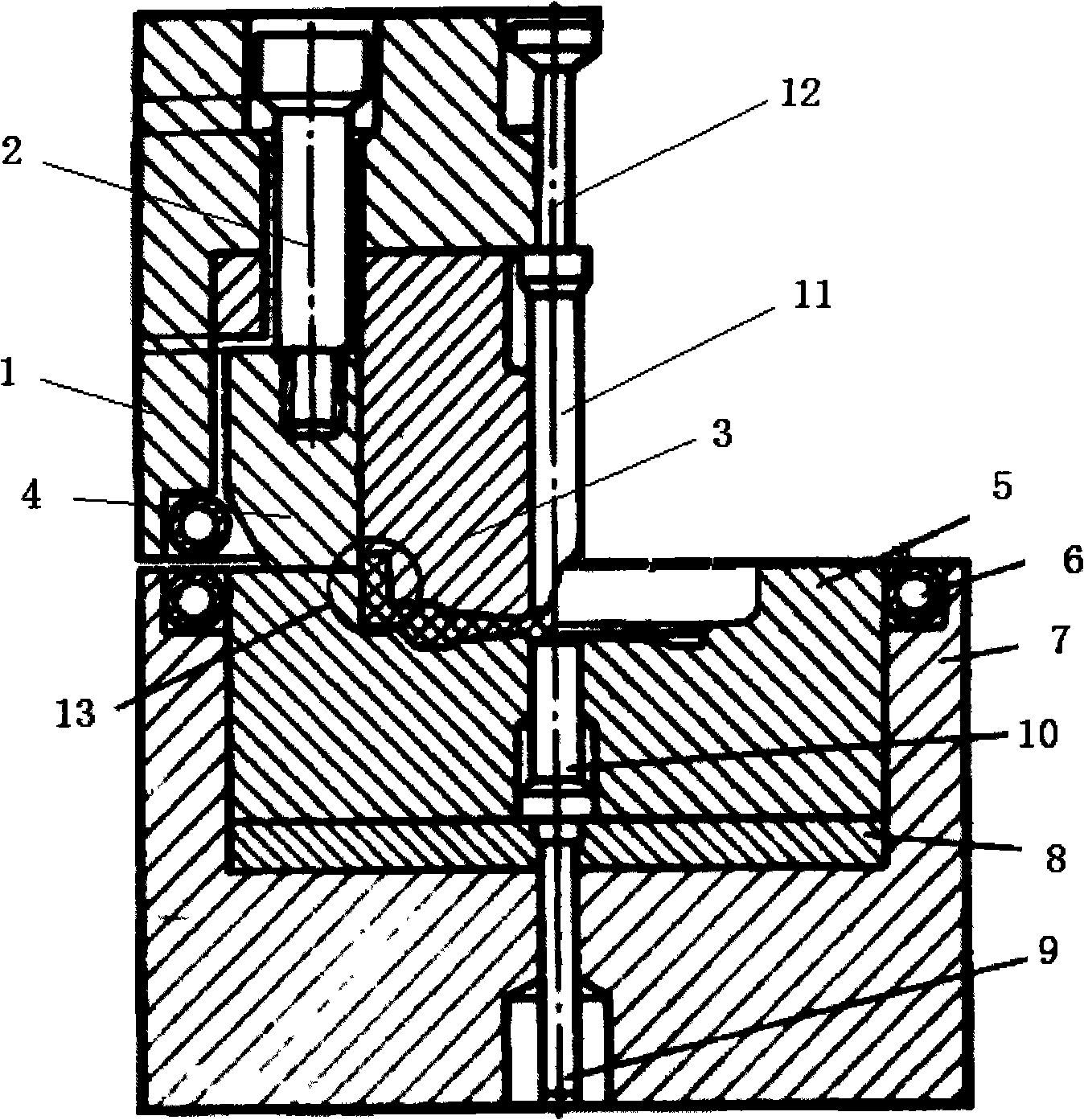

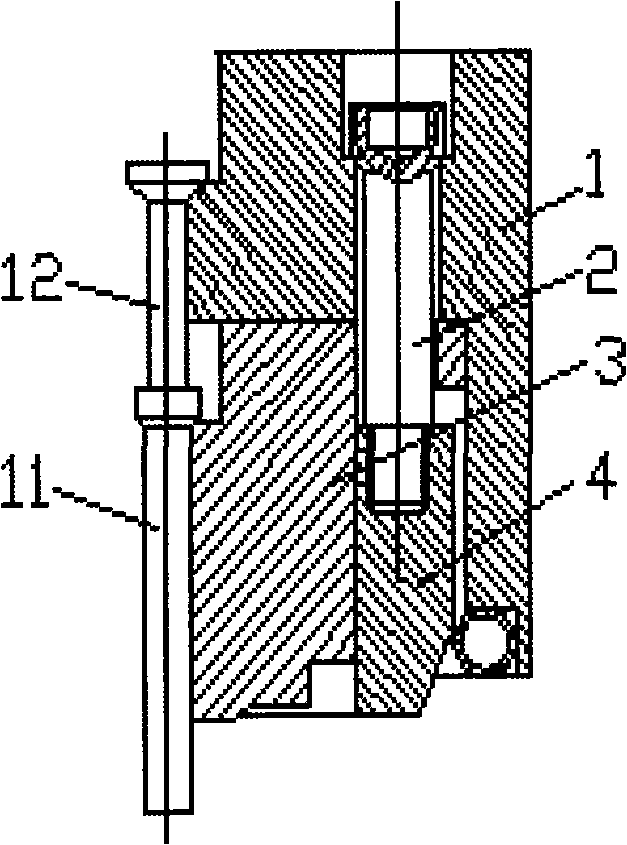

[0026] Such as figure 1 and figure 2 As shown, this embodiment 1 includes: upper die base 1, inserting bolts 2, punch 3, movable inserting sleeve 4, die 5, lubricating ring 6, lower die base 7, die backing plate 8, lower ejector rod 9. The lower ejector rod 10, the upper ejector rod 11, the upper ejector rod 12, and the metal to be forged 13, wherein: the edge of the contact surface of the upper mold base 1 and the lower mold base 7 is respectively surrounded by a lubricating ring 6, and the movable insert The sleeve 4 is fixed on the upper mold base 1 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com