Ground water back pouring cyclic utilization method

A groundwater and reinjection well technology, which is applied in geothermal power generation, heating devices, and other non-combustion heat generation, can solve the problems of groundwater waste and recharge difficulties, and achieve the effect of short well cleaning time and easy recharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

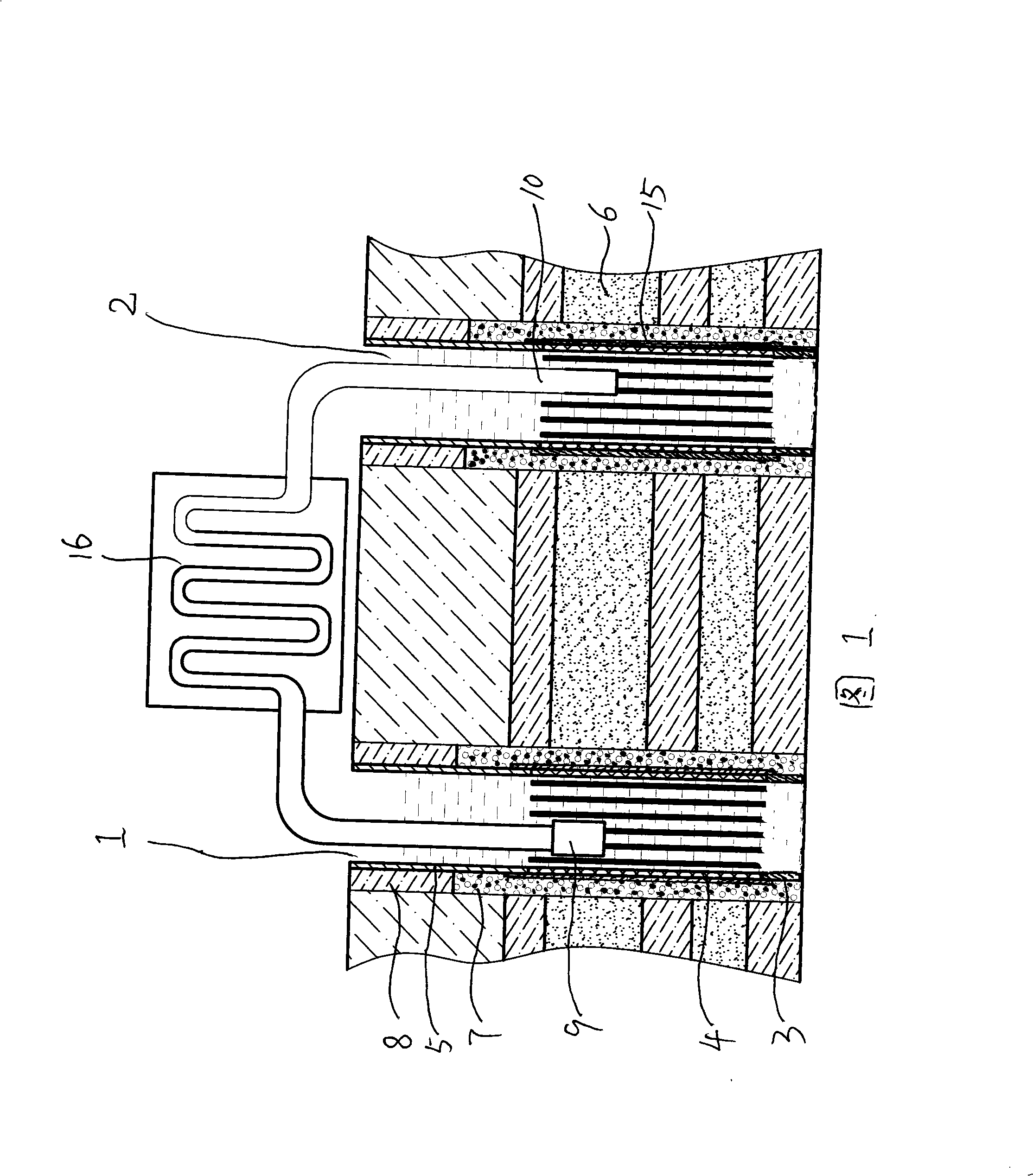

[0045] Embodiment 1: the first step, determine wellbore position and borehole, according to local hydrogeological situation, determine pumping well 1 and reinjection well 2 to be 150 meters, drill pumping well 1 earlier, in the precipitation influence radius of pumping well 1 Drill the wellbore of reinjection well 2 at the 3 / 5 position;

[0046] The second step is to hoist the well pipe, butt and fix the well pipe according to the order of the sedimentation pipe 3, the water filter pipe 4 and the well wall pipe 5, and then put it into the well hole of the pumping well 1 and the well hole of the reinjection well 2 that have been drilled ; And the water filter pipe 4 in the pumping well 1 and the reinjection well 2 is located at the same horizontal position;

[0047] The third step is to fill the filter material. According to the geological structure of the sand layer 6 where the filter pipe 4 is located, a filter material 7 of a corresponding size is selected, and the selected ...

Embodiment 2

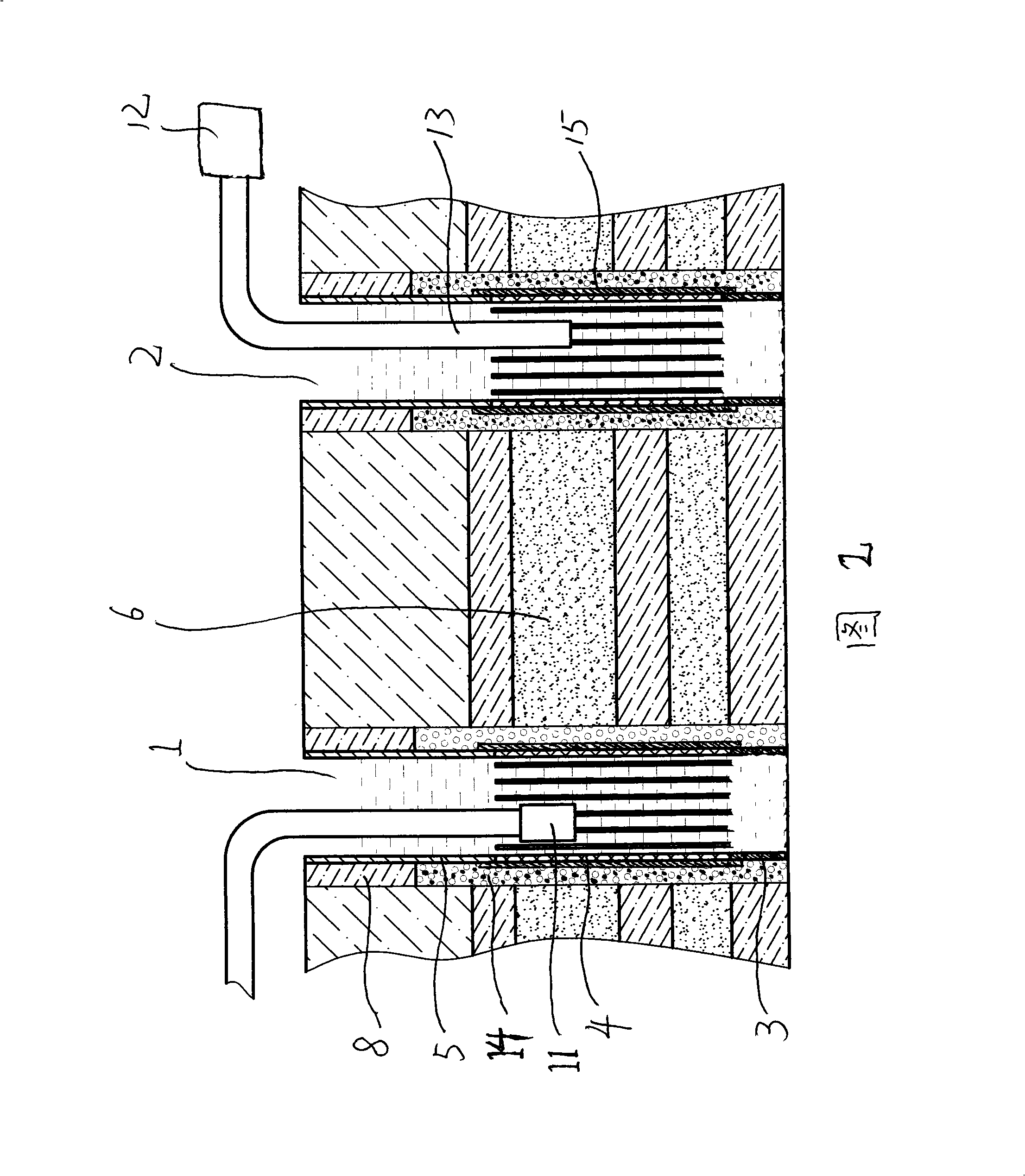

[0052] Determine the location of the well hole and drill the well hole. According to the local hydrogeological conditions, determine the pumping well 1 and the reinjection well 2 to be 1000 meters. 2 well holes; and a double-layer 60-mesh filter screen 15 is wound around the filter pipe 4. All the other steps are the same as in Example 1.

Embodiment 3

[0054] Determine the location of the wellbore and drill the wellbore. According to the local hydrogeological conditions, determine the distance between the pumping well 1 and the reinjection well 2 to be 600 meters. 2 well holes; and a double-layer 80-purpose filter screen 15 is wound around the filter pipe 4, and the remaining steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com