Apparatus for carrying out plasma chemical vapour deposition and method of manufacturing an optical precast product

一种化学气相沉积、等离子体的技术,应用在谐振腔的谐振器领域,能够解决衬底管有害、高纤维衰减、不稳定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

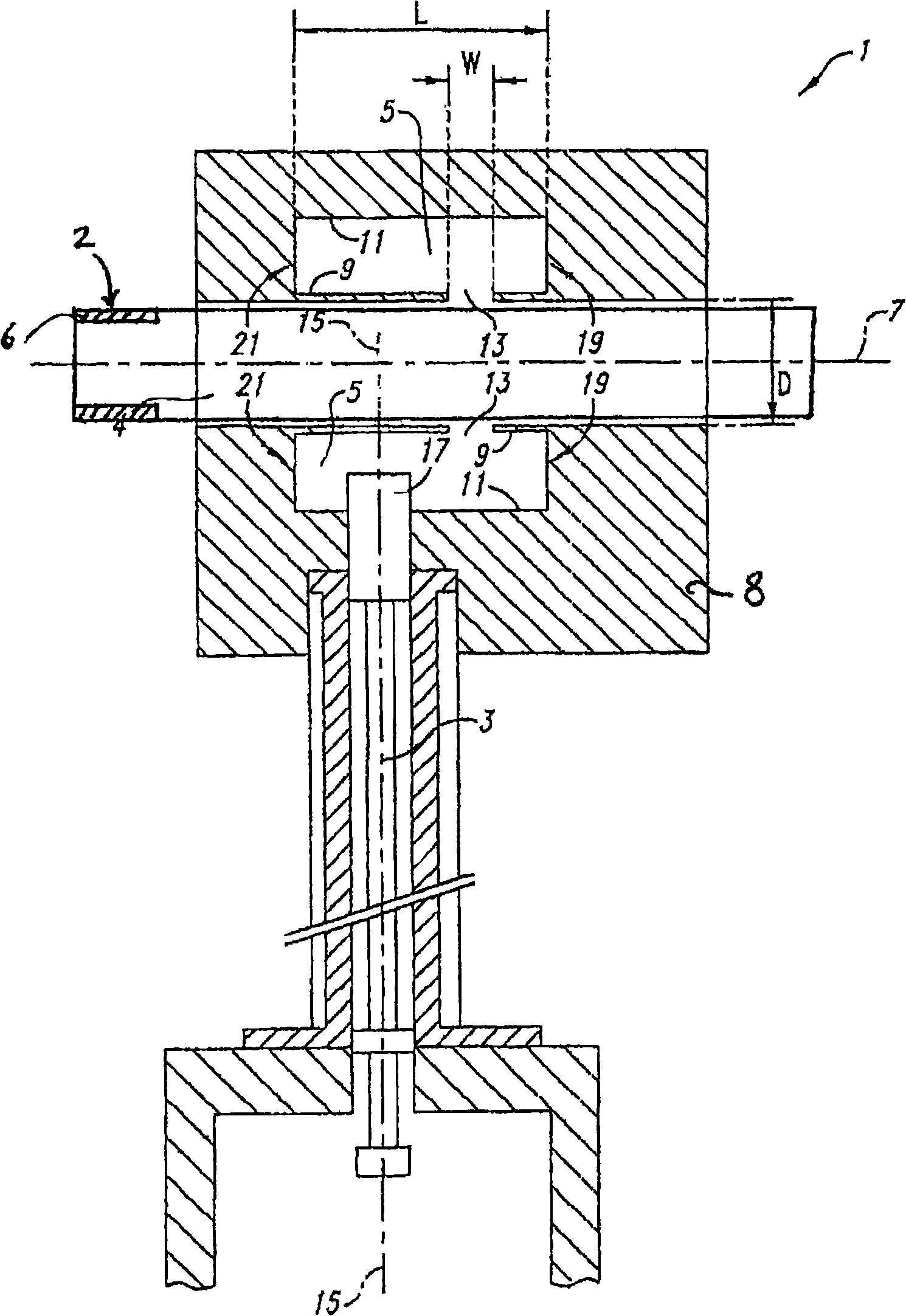

[0029] figure 1 is a cross-sectional view of a part of a PCVD apparatus 1 according to the invention. The device 1 comprises an elongated microwave guide 3 connected to a klystron (not shown) on a resonant cavity 5 extending circularly symmetrically around a cylindrical axis 7 . During deposition, the resonant cavity 5 moves back and forth along the cylindrical axis 7 so that the plasma region moves continuously along the length of the substrate tube (not shown). The resonance cavity 5 is substantially annular with a cylindrical inner wall 9 and a cylindrical outer wall 11 . The cylindrical inner wall 9 comprises a slit 13 which (in this embodiment) extends over the entire circumference around the cylinder axis 7 (in a plane perpendicular to the plane of the drawing). The microwave guide 3 has a (central) longitudinal axis 15 which extends substantially perpendicularly to the cylinder axis 7 . The longitudinal axis 15 and the slit 13 are offset relative to each other in suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com