Large piece weight molybdenum, tungsten, titanium stick and wire coil blank

A large unit weight, titanium rod technology, applied in the field of large unit weight molybdenum, tungsten, titanium rods and coil blanks, can solve the problems of poor quality and small unit weight, and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

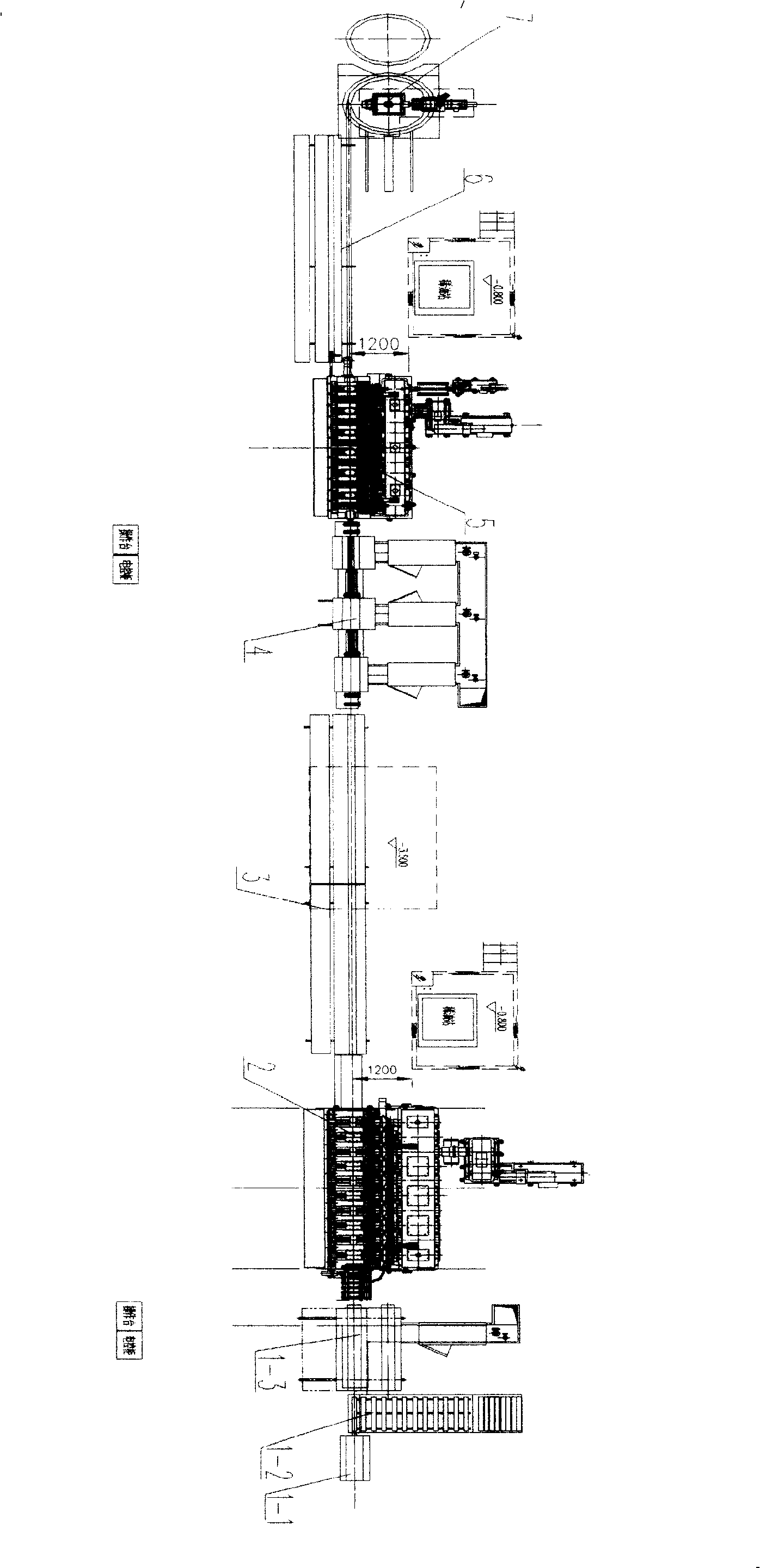

[0020] The sintered molybdenum billet with a net weight of 25 kg of Φ50~53×1300 mm is placed in front of the push rod in front of the furnace by the billet feeding mechanism, and pushed into the induction heating furnace (the current is zero when there is no material in the furnace); the furnace can Two billets are placed, and the temperature of the material is controlled by the feedback of the photoelectric thermometer. One can be pushed out every 3 minutes (the heating time of each molybdenum billet is 6 minutes); It is pulled out from the furnace mouth at a speed of m / s, and quickly sent to the rough rolling mill for rolling. The rough rolling start temperature is 1400-1500°C; The size is a hexagonal or round wire rod with an inscribed circle diameter of 16.2 mm, and the temperature drops to 1150-1200 °C. Its deformation resistance is also increased from 50MPa at the beginning of rolling to 220MPa, and the maximum elongation coefficient is also reduced from 60% to 7-8%. If...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com