Assembly method and component for fine process of cylinder of diesel engine

A technology for assembling components and cylinder blocks, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of spindle hole deformation, inability to meet processing requirements, and difficulty in cylinder block processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

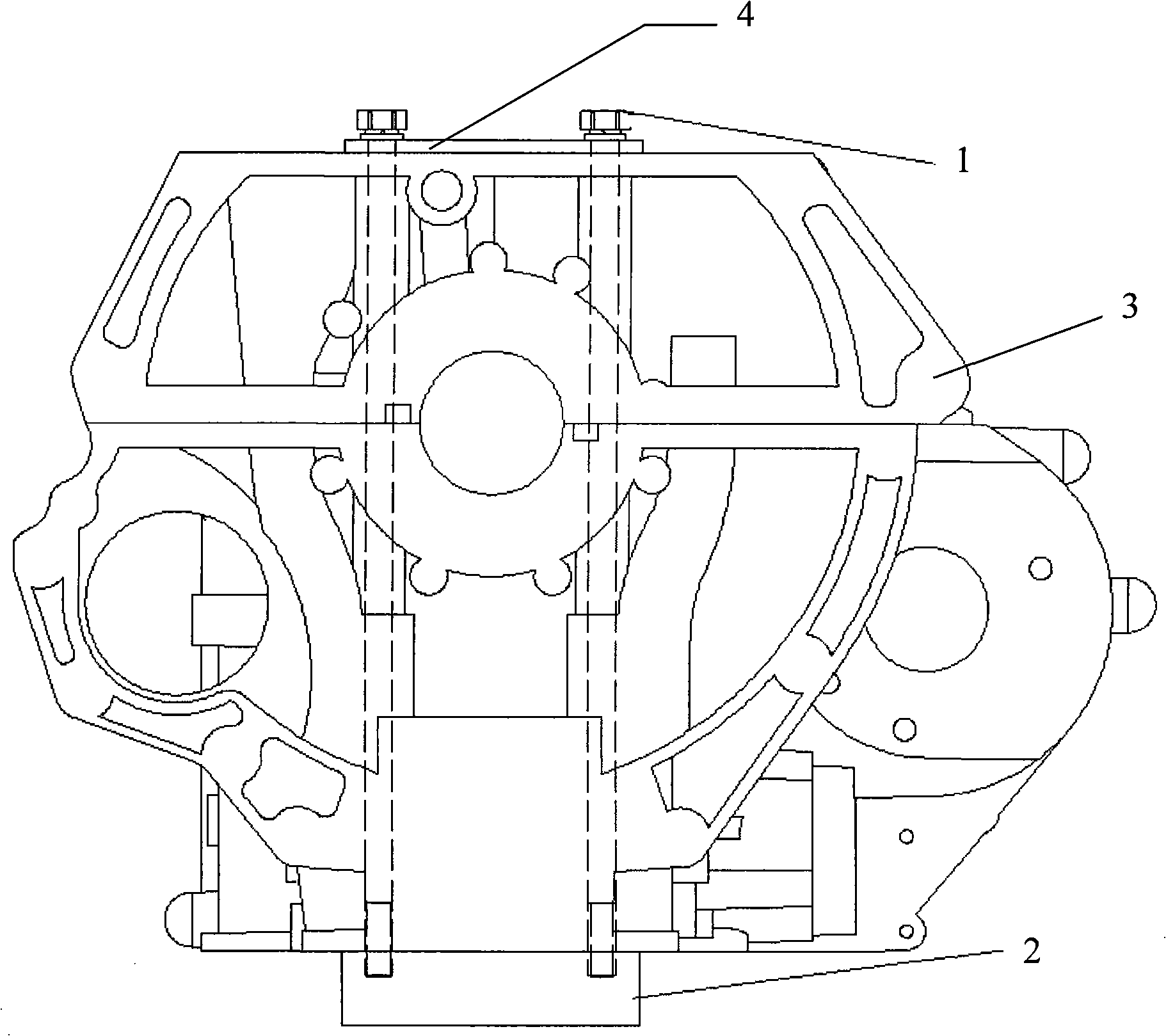

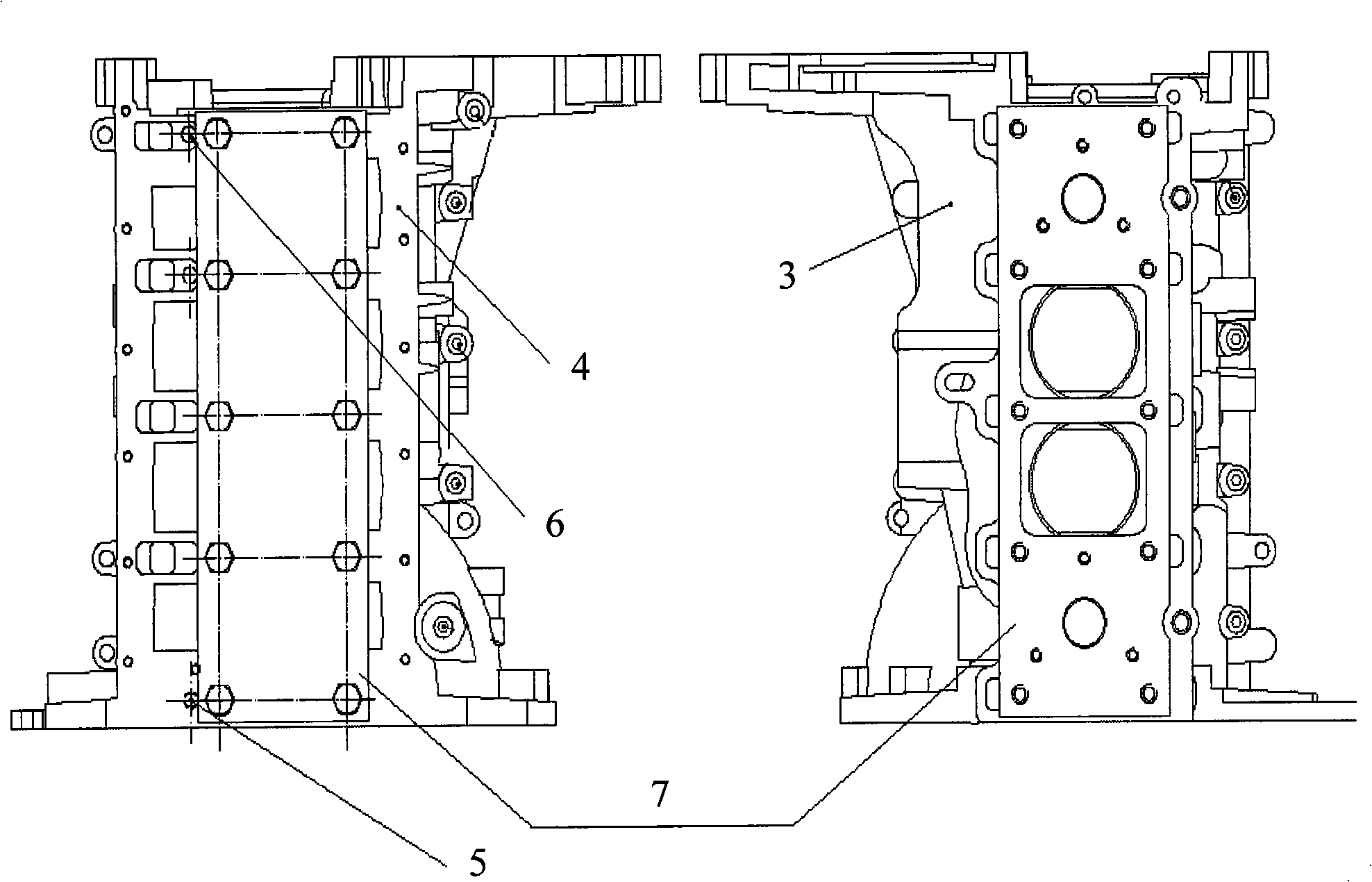

[0016] As shown in Figures 1 and 2, an assembly method for finishing the cylinder block 3 of a diesel engine includes the steps of: designing and manufacturing a simulated cylinder head 2 according to the actual cylinder head; the cylinder block 3 is provided with a positioning round pin 5 , locate the round pin 6, align the base 4 with the cylinder block base installation device 7 on the cylinder block 3, position the round pin 5, and locate the round pin 6, so that the base 4 is installed into the cylinder block 3; use the simulated cylinder head 2 Connect the cylinder block 3 and the frame 4 for machining.

[0017] Among them, the simulated cylinder head 2 is designed according to the actual cylinder head (W3000 cylinder head), considering the assembly height, assembly torque, and stress generated by machining, and acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com